How Does a Sandblaster Work? Wish You Knew Before

Whether it is for shot blasting, scraping, stripping or even cleaning surfaces, the sandblaster is the ideal tool. But few people think about how exactly this works. In this article, I will try to explain how does a sandblaster work?

The principle of operation of a sandblaster is extremely simple : A strong jet of air is generated which is mixed with a blasting agent. The required air pressure is generated by special compressors and the powder-like abrasive can either be mixed in dry or with water from a collecting container.

This special sand-air mixture is then blasted at high speed via a hose and nozzle system onto the surface to be treated. In the process, surface particles are loosened out due to the abrasive blasting effect and then removed. Surfaces are thoroughly cleaned of impurities, rust, paint or scale. Depending on the process, different degrees of cleaning can be achieved.

What is sandblasting?

Sandblasting is a method of surface treatment and is used to clean metal surfaces and to matt glass. The sandblasting of metals fulfills a double function, as the surfaces are both cleaned and roughened.

This blasting effect is achieved by so-called blasting agents such as corundum or garnet sand, which hit the surface at high speed and thus clean and roughen the metal surfaces in one machining process. The surface structure is determined by the abrasive used and the choice of degree of cleaning depends on the subsequently required surface protection.

The Main Tasks Of The Sandblaster

Before you understand how does a sandblaster work, you need to carefully study all the possibilities of using the equipment:

- removal of the appeared rust;

- removal of scale and molding soil from a car body;

- getting rid of old paint layers from wood;

- preparatory measures before matting;

- removing burrs and polishing that has aged;

- preparation before further painting or applying anti-corrosion agents.

- create decorative effects on wood or concrete.

Carrying out all of the above activities provides for a minimum financial investment. At the same time, high quality cleaning is guaranteed.

How Does a Sandblaster Work?

First of all, you should familiarize yourself with how does sandblasting equipment works.

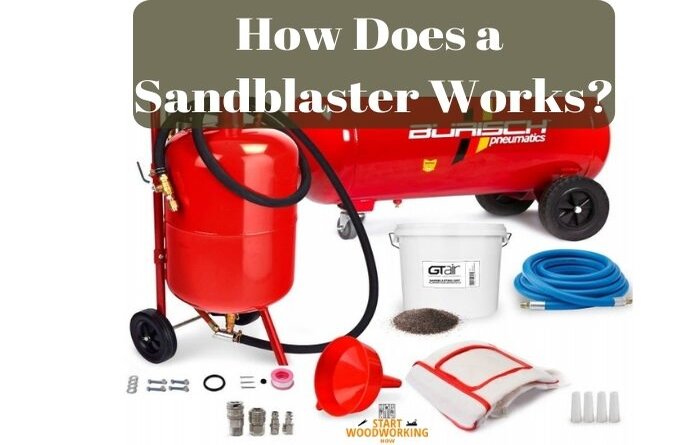

Structurally, each sandblaster consists of:

- Air compressor;

- Accumulative receiver;

- The main tool (pistol);

- Containers with abrasive particles;

- Automation and control systems;

- Connecting hoses

The principle of operation of a sandblaster is comparable to a spray gun:

- Air is supplied to the compressor and accumulated.

- When the maximum pressure is reached, air enters the gun.

- A vacuum is formed, the air flow draws in the sand. The abrasive particles are accelerated up to 40 m / s.

- The air with the abrasive exits through the nozzle from the gun and enters the treated surface.

The main component of the installation is a compressor that delivers compressed air at different speeds. Its characteristics will be leading when choosing a product.

The nozzle is used to direct and localize the jet. The best material for it is tungsten carbide, boron. You should not choose ceramic or cast iron nozzles, as they have a short service life.

The sandblaster additionally includes cables, power supply and hoses of the required size. More expensive models are equipped with an automation and control system.

Automation increases safety: when the worker releases the gun, a shutdown occurs. The control system not only turns on and off the compressed air supply, but also allows you to go to idle.

Hoses must withstand pressure, have minimum internal resistance. Their diameter and length affect the overall performance.

The operation of a sandblaster is related to its type. Nevertheless, sandblasters share pretty much some common principles.

They use the finely ground silica sand to scrub and clean rust, paint and other material from surfaces. These are mainly made of metal.

The sandblasters to get to the end of the stain are equipped with a gun designed in ceramic with an interior coating which minimizes the risk of liquefaction of the sand.

This gun is compressed air, which allows it to shoot the sand on the surface to be abraded with high speed. The distinguishing principle of the different types of sandblasters is the process by which the sand is introduced into the gun.

The sandblasting gun is equipped with a small tank that must be connected to an air compressor, for this reason it is very often called a compressor sandblaster gun .

A special material is placed inside the tank, sold in building material resales, and consists of silica sand or synthetic abrasive sand , both dry, previously filtered and with a defined but variable grain size, so as to be able to choose the most suitable one for the job to be performed.

In this way, the pressurized air, passing quickly into the gun, sucks the sand which, impacting on the material to be treated, is able to remove paints, rust and oxides. from all those surfaces which, having irregular shapes, are difficult to treat with abrasive paper.

Remember to set the compressor at a pressure of at least 8 bar in order to always work at full capacity; furthermore, to obtain optimal results, it is important to keep the jet of air and sand never perpendicular to the material to be processed but always in angled positions .

Finally, as it lends itself well to any surface, as long as it does not contain plastic elements, one must keep in mind not to insist too much on the same area, especially when dealing with delicate materials such as aluminum, in order not to risk removing the structural material.

How different types of sandblasters works?

There are basically three types of sandblasters. These are: the gravity-fed sandblaster, the pressure sandblaster and the siphon sandblaster.

How Does Gravity-Fed Sandblaster Work

This type of sandblaster is gravity fed. The gravity-fed sandblaster is made up of three important parts:

- the pressurized air tank (compressor),

- the pressure hand gun with air hose

- the hopper that is located above the gun.

The principle of operation of the gravity fed blaster is the following: the hopper which is filled with silica sand and the air pipe is connected to the tank. Two reactions occur when the gun trigger is pulled.

First, as long as the trigger is depressed, compressed air is released from the gun air hose. Then, an opening is created at the level of the hopper.

The sand then comes out thanks to the pressure of the air which propagates in the barrel coupled to the force of gravity. It must be said that it is a sandblaster fed by gravity.

In fact, the hopper is filled with silica sand and it is connected to the compressor by means of an air pipe.

How Does Pressure Sandblaster Work

Pressure sandblasters are the most popular because of their lower cost and ease of use. They are simply large bottles filled under pressure with silica sand. This concept can be likened to that of an aerosol.

The principle of operation of the pressure sandblaster is the following: The sandblaster gun, often with two hands, is connected to the port on the top of the cartridge via a very special hose. It is able to counter the abrasive effects of sand.

When the gun trigger is pulled, air and sand are forced out of the cylinder together. The advantage of this system is the virtual non-existence of maintenance and servicing.

This represents a great advantage for the pressure sandblaster. However, it has a drawback. As the bottle is hermetically sealed, the sand driven out cannot be collected for reuse.

We are therefore obliged to change the empty bottle. All in all, it’s a good sandblaster.

However there are some disadvantages which can be summed up as follows. Because the cans are closed, the expelled sand cannot be collected for reuse.

How Does Siphon Sandblaster Work

This is the sandblaster found in most handymen. It is used to perform cleaning and stripping of surfaces.

Also called siphon sandblaster, it is made up of three parts: the gun, the pressure tank and the sand tank.

The sandblaster gun has two different hoses which connect one at the bottom of the handle and the other below the barrel. The pressure tank is the air compressor.

This is why it is often said that the siphon sandblaster is similar to the pressure sandblaster. The sand tank is in the form of any container or bucket.

When the gun is triggered, the air creates the suction of the sand from the tank towards the hose then the gun to finally be fired into the barrel.