Density of Wood

Do you want to start a woodworking project and you wonder what type of wood to choose? One of the most important factors in your decision should be density of wood. Let’s see what is density of wood and why is it so important?

Density is mass per unit volume. The density of the wood relates strictly to the solid substance of the wood, without taking under consideration the water and air within the wood structure. Wood density or wood specific gravity is measured in kg/m3 and it varies from one wood species to another.

How is the density of wood measured?

Density kg/m3 = [mass of wood] / [volume of wood]

A green tree contains up to 75% water, which is then lost, depending on the drying. In general, the density of the wood is measured at different degrees of humidity, the wood being hygroscopic.

Usually rangers measure the weight of a given volume of wood that has been air-dried. Depending on the country, conventions differ about air drying: the fraction of water remaining within the wood sample could also be 12%, or 15%.

Scroll down to see some density chars of the most common types of wood used!

In order to determine the density we need to determine the green volume!

Green volume are often measured using two different methods :

A) Using the dimensional method which calculate the volume of the wood assuming that is a regular cylindrical shape.

Using a caliper you measure the diameter at different points and using a ruler you measure the total length of the wood.

When you measure the diameters with the caliper, be careful not to pressure the caliper blades on the wood.

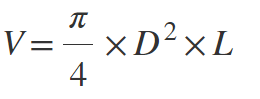

Knowing the length of the wood sample and also the mean diameter we can use this formula to determine the volume:

D = Diameter of Wood

L = Length of Wood

After we know the green volume, we need to weight the wood and after that we can calculate the density using the following formula:

m = mass (lb)

V = Volume (ft3)

To make this easier we’ve created this density of wood calculator!

Density of Wood Calculator

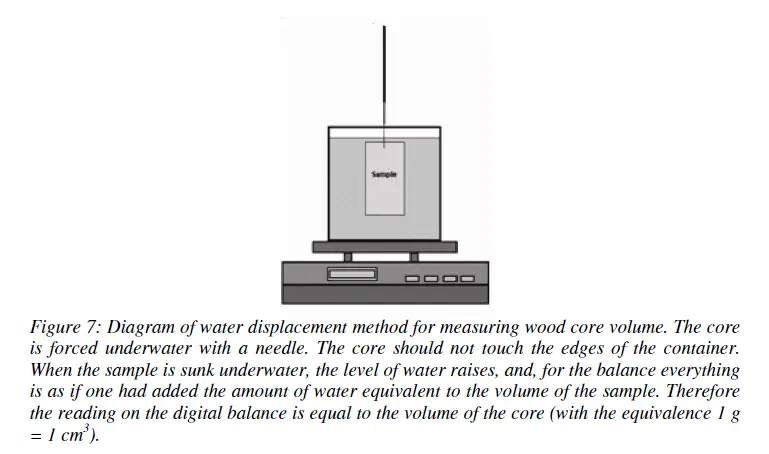

B) Using the water-displacement method which calculate the volume of the wood. This method is great for irregularly shaped wood samples.

First fill a container with water that is capable of holding the wood sample. Place this container on a digital balance of precision of minimum 0.01 g.

To not take into account the container weight, the digital balance should be re-zeroed (indicated the reading zero).

The container should not be filled completely with water. Take the sample and carefully sunk it within the water and make sure that is completely under.

To make this procedure even better we recommend that you use a thin needle. In this case the sample will not touch the surface or the bottom of the container.

The weight of the displaced water that is measured is equal to the wood sample’s volume since the water has a density of 1.

The digital balance should always be re-zeroed after every measurement.

Two type of density

You need to know that there are primary two types when it comes to density: apparent density and conventional density.

Sound confusing? Let’s clarify this!

Due to the fact that wood in general is a porous material, its conventional density differs from its apparent density.

Apparent density is the ratio, expressed in g / cm³, between the apparent mass and volume of wood. It varies from one species to another. It can also vary depending on the same species the growth conditions, the width of the annual rings, the proportion of late or early wood, the existence of inlays and humidity.

Conventional density (ρc) represents the ratio of wood mass a.u. (anhydrous) and the maximum volume of the same sample (the maximum volume is the wood with saturated moisture fiber)

Depending on the apparent density we can classify the wood as follows:

- easy: alder, fir, chestnut, douglas fir , juniper, spruce, American walnut, pine, poplar, willow;

- semi-hard: hazelnut, maple, cherry, mulberry, larch, birch, maple;

- hard: green alder, hornbeam, horn, beech, ash, field maple , maple, plum, acacia, oak, elm, english yew etc.

Density is a reliable indicator of :

- Strength

- Stiffness

- Joint Strength

- Fire resistant

- Ease of machining

Wood Types

There are primarily two type of wood : Hardwood and Softwood. Each type comes from different types of trees so they are classified separately.

Hardwoods comes from Deciduous Trees. Deciduous trees have covered seeds and annually shed leaves.

Softwoods comes from Conifers. Conifers trees have uncovered seeds and cones which fall on the ground.

The wood density differs from type to type taking into account:

- the environment of the tree

- the tree species

- the tree area measured for density calculation.

Generally the branches have a lower density value compared to the trunk of the tree. A lower density is present in the fast growing trees. On the other hand older and slowly growing trees have an increase density

It varies within the plant, during the life of the plant, and between individuals of identical species. Also the branches and also the outer a part of the trunk tend to have a lighter wood than the pith.

Density Charts of Different Wood Types

Density of Hardwoods

| Type of wood | Density Dry Wood [kg/m3] | Density Dry Wood [lb/ft3] |

| Alder | 400-680 | 24.97 – 42.45 |

| Hornbeam | 990 | 61.80 |

| Cherry | 600 | 37.45 |

| Oak | 600 – 900 | 37.45 – 56.18 |

| Sessile Oak | 760 | 47.44 |

| Acacia | 760 | 47.44 |

| Ash | 920 | 57.43 |

| Black Ash | 720 | 44.94 |

| Manna Ash | 720 | 44.94 |

| Beech | 950 – 970 | 59.30 – 60.55 |

| Blackberry | 560 | 34.95 |

| American sycamore | 670 | 41.82 |

| Chestnut | 590 | 36.83 |

| Walnut | 960 | 59.93 |

| European Linden | 790 | 49.31 |

| Willow | 500 | 31.21 |

| Ebony | 1120-1220 | 69.91 – 76.16 |

| Apple | 650 – 850 | 40.57 – 53.06 |

| Olive | 920 | 57.43 |

| Bamboo | 320 – 400 | 19.97 – 24.97 |

| Basswood | 325 – 590 | 20.28 – 36.83 |

| Birch | 500 – 700 | 31.21 – 43.69 |

| Elm | 530 – 610 | 33.08 – 38.08 |

| Gaboon | 430 | 26.84 |

| Gum Black | 590 | 36.83 |

| Gum Red | 540 | 33.71 |

| Hackberry | 620 | 38.70 |

| Hickory | 610 – 920 | 38.08 – 57.43 |

| Logwood/Blackwood | 900 – 910 | 56.18 – 56.80 |

| Magnolia/ Cucumbertree | 570 | 35.58 |

| Mahogany | 500 – 850 | 31.21 – 53.06 |

| Maple | 610 – 750 | 38.08 – 46.82 |

| Poplar | 350 – 500 | 21.84 – 31.21 |

| Teak | 650 – 900 | 40.57 – 56.18 |

| Redwood | 450 – 510 | 28.09 – 31.83 |

| Elder tree | 620 | 38.70 |

Density of Softwoods

| Type of wood | Density Dry Wood [kg/m3] | Density Dry Wood [lb/ft3] |

| Cedar | 368 – 577 | 22.97 – 36.02 |

| Cypress | 520 | 32.46 |

| Douglas Fir | 510 | 31.83 |

| Silver fir | 470 | 29.34 |

| European Yew | 700 | 43.69 |

| European Juniper | 550 | 34.33 |

| Pine | 350-850 | 21.84 – 53.06 |

| Spruce | 790 | 49.31 |

| Norway spruce | 430 | 26.84 |

| Fir | 830 | 51.81 |

| Hemlock | 500 | 31.21 |

| Larch | 500 – 550 | 31.21 – 34.33 |

Why is the density of wood important?

In your woodworking project you can already know how a type of wood will perform based on the wood density.

Let’s see why!

Density of wood is a very important trait for furniture making. There are two main important mechanical properties: strength and stiffness.

Research has shown that a increase density equals an increase strength, hardness and stiffness of sawn timber.

The basic purpose of furniture is to hold a load so it’s a must to choose the right wood that has the proper strength and stiffness to perform this task, be it to support a person or a significant load of books.

Wood within the density range 400–800 kg/m3 (oven dry mass, green volume basis) is preferred.

Woods that have lower density have also inferior strength, stiffness properties and manufacturing characteristics.

On the other side if the density is higher than the threshold mention above, will have some disadvantages like : more costly to process and may yield a piece of furniture heavier than desired by the customer

In practice, the density of wood really makes a big difference, considered a crucial indicator of general wood quality. For example, wood is harder, where the density is higher.

This means that the material will be more difficult to handle thus affecting the cost of shipping the lumber and also the overall weight of the structure.

The density of the lumber is additionally a very important design consideration. Most specifically, connections in wood design are hooked in to the particular gravity of the lumber being connected.

The National Design Specification publishes an average relative density value for species of wood utilized in structural design. Individual pieces of lumber will vary in relative density .

One among the sole negative features of upper density wood is that it does show greater shrinkage after drying.

The density (specific weight) of wood is the main indicator of the value of the thermal energy – the calorific value of the wood.

The relationship is direct. The denser the structure of wood in the forest, the more fuel wood substance (caloric energy) contained.

Check this guide on Caloric Power of Wood

The influence of humidity on density of wood.

Wood moisture greatly influences the density of wood, and some variation may occur due to swelling or shrinkage of the wood.

Wood is know to be a hygroscopic material (tending to absorb moisture from the air) so it’s density is influenced by the weight of water in a given volume of wood and the volume of wood at a stated moisture content.

Because of this the density of wood will vary with moisture content.

When reporting the density value of wood the moisture content must be also reported.

The humidity of the wood for construction, and especially its value, has a great influence on the properties of the wood material.

Wood moisture is the physical property that influences the appreciation of the physical or mechanical characteristics of this material.

In engineering design, density values are usually supported oven dry weight and volume at 12% moisture content.

Density is correlated to the mechanical properties of wood therein as density increases, the strength of wood increases.

The density of green pine wood is 700kg / m³, and the dry pine has 600 kg / m³ , beech wood has 950 kg / m³ green, dry has 750 kg / m³.

It can only be said that for the ordinary species, which have a lower density than water – 1000 kg / m³, the dry wood has a lower density than the green one, for the same tree species, otherwise, it depends on the respective essence.

How to determine the humidity of wood.

The moisture content of the wood material is determined on samples taken from the respective wood. These samples are weighed beforehand and then dried at 105 ℃ up to constant weight.

The difference in weight obtained is related either to the weight of the wet wood and is called relative humidity or to the weight of the dry wood and we call it absolute humidity.

The value of the ratio in both situations is multiplied by 100. Thus, the percentage moisture content of the wood is obtained.

What Wood has the highest wood specific gravity ?

For practice, the indicative values are obtained from graphs that give the dependence of the density of humidity.

Each species of wood has the characteristic average density.

For comparison, the absolute density (absolute dry wood) is taken; from this point of view all wood species are classified into the following 6 classes:

- very heavy wood species (ρo> 0.8 g / cm3): birch, horn, ebony, eucalyptus;

- heavy wood (0.71 <ρo <0, 8 g / cm3): acacia, hair, oak, yew, gorun;

- semi-heavy wood (0.61 <ρo <0.7 g / cm3): beech, hornbeam, elm, ash, apple;

- semi-light wood (0.51 < ρo <0.6 g / cm3): juniper, chestnut;

- light wood (0.41 <ρo <0.5 g / cm3): spruce, linden, poplar;

- very light wood (ρo <0.4 g / cm3) : fir, pine.