What is a Jointer? Is Jointer the Best Hand Tool?

Even the smallest children know exactly what a hammer, saw, screwdriver and even a drill or grinder. But regarding what is a jointer, even the name seems foreign by most people.

This attitude is completely normal because the jointer is not a small piece of equipment that you can easily put in your toolbox. A jointer is a fairly large but extremely necessary material found in the workshop. It is used in the same way as the router or the planer.

The jointer is a special kind of planers that can be fixed motionless thanks to special equipment. Usually a long base plate is used for this purpose. Initially, the jointer is designed for finishing wood. Joiners as a category of electric planers have the largest dimensions and significant weight – thus, it is not possible to keep them in the process by weight.

Throughout this article, you will know what is a jointer and a little more about this very useful and practical tool.

What is a Jointer purpose?

When considering what a jointer is, we note this tool is used to change the surface quality of wood.

It depends on him how much the final product will be pleasant.

The jointer can look in the most different way, the mechanical embodiment is represented by a combination of three main elements:

- The body in most cases is made using wood, but there are also metal options.

- The product with a wooden case is suitable for working with soft rocks.

- The metal is designed to withstand heavy loads.

When considering what the jointer is for, we note the following points:

- It is used when it is necessary to align large fragments. In this case, the work piece may have a large area and length.

- Installed cutters can have a width of up to 8 cm, while the block is also characterized by a sufficiently large size.

- The first holding of the tool causes the formation of small chips, the second becomes the cause of obtaining long, uniform chips.

- On sale there are a variety of types of tools, the choice is made depending on the task.

The manual jointer version is different from the electric one, which has a complex structure. It consists of the following:

- The persistent handle with which the force is transmitted.

- Bell for connecting a vacuum cleaner. It should be kept in mind that at the time of operation, a large number of chips can form. In order that it does not have a negative impact on the work, a special vacuum cleaner is connected, which immediately after the appearance of the chips carries out its collection.

- The control buttons allow you to set the basic parameters of the device.

- The hand screw is found on almost all devices. It is required to change the depth of planing.

- There is also a lateral emphasis, due to which the width of the working surface is changed.

- Protective hinged cover that eliminates the possibility of damage.

- Sole. It is in contact with the treated surface, often represented by aluminum.

- Many devices are characterized in that they have a built-in battery. In addition, there is the possibility of connecting a cable.

What is a jointer used for?

The jointer is a kind of woodworking machine allowing to transform a rough part into a tool with four well parallel faces and squares. It also offers the user the opportunity to use his planer to work with wood, in order to have the desired dimensions.

To do this, the shaft with sharpened irons, in particular a circular saw blade, is propelled by a motorization system. With the right tool, the user begins by cutting the wood, according to his expectations.

The tasks can thus be summarized in two very distinct stages. It is necessary, in fact, to start by planing, before planing. It is therefore an ideal way to do away with twisted creations.

The use of a planer and thicknesser makes it possible to have a flat face which will use a reference to machine the remains.

This material is thus essential in any project to pay particular attention to the perfection of wooden elements, and this, so as to have flat parts.

It must therefore have its place in the workshops to successfully plan rough wood tools.

How does a jointer work?

To understand how a jointer works, let’s take it step by step.

First, take a piece of rough wood and lay it lengthwise on the entry table. It must be set beforehand so that we can have the desired thickness.

The level of the input and output table differs by the desired thickness of the wood.

Then, the carpenter gradually pushes the piece towards the exit table. Afterwards, the wood is pressed against the table and the guide parallel to the axis.

And finally, the iron-carrying shaft in turn automatically does its job without any intervention once it is properly adjusted in maintenance. The raw wood comes out flat and flat.

Operation and characteristics of a jointer

For neophytes, a jointer works like a fixed and inverted planer to equalize a wood, that is to say that the blades which are used to remove the material are located under the wood and not on it.

The other difference with the planer is that while this one acts freely on the wood while leaving possible all the errors of wrought, the jointer has a perfectly flat table which is used as template in order to obtain a face of wood perfectly straight.

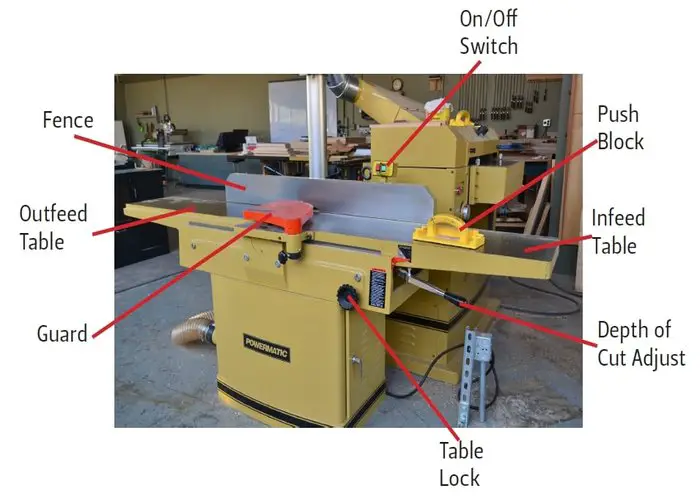

A jointer is therefore a workshop machine which consists of a frame on which are maintained:

- An entry table on which the wood to be planed is slid towards the cutting head.

- A cutting head, usually a rotating head with irons (blades). The rotation of the irons nibbles the roughness of the wood as it advances.

- A guard or bridge which supports the wood on the cutting head.

- An output table which is the main table, the template on which the wood to be planed must be supported when it passes over the cutting head.

- A lateral guide perfectly perpendicular to the exit table which supports the edge. Some guides are adjustable in order to plan with an adjustable angle between the facing and the edge.

- An electric motor used to drive the cutting head in rotation. This motor is supplied either with single-phase 220 V current for standard machines, or with three-phase 380 V for industrial joiners.

What is the difference between a jointer and a planer?

The geometry of the jointer makes it possible to dress on two sides but cannot calibrate the board. To be able to achieve this end, a planer must be used.

This tool will make it possible to have two surfaces parallel to the two faces. The work accomplished by these two tools is rather complementary.

To get a clearer and more precise idea of how these two tools work, the jointer is used to have a flat board, and the planer ensures two perfectly parallel faces.

The jointer is much more practical for certain specific tasks. To find out more, contact a professional as soon as possible. He will be able to provide the most exact answers.

Jointer types

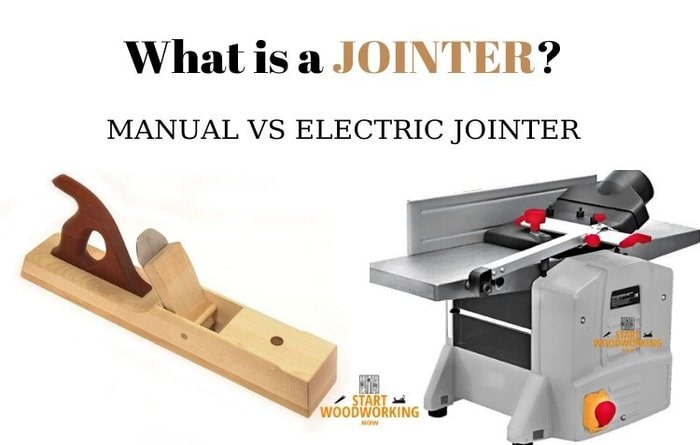

The jointer has two types: manual and electric.

Hand jointer

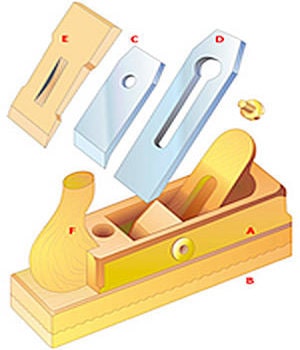

This is a metal or wooden tool, the design of which includes:

- housing;

- pen holder;

- blade (knife).

The block length is 90 cm and the width of the blades is 8 cm. For mini-models, half-shirts, the sole length does not exceed 50 cm. This is convenient for processing large parts.

Strength is required to trim the workpiece. Professionals often use an electric jointer. Electric jointers have the following advantages:

- Larger mass and downforce.

- More precisely processes the workpiece.

- Work is much faster.

- The tool has a set of interchangeable nozzles.

A feature of using an electric jointer is the possibility of attaching it to a workbench . It turns out a machine replacing special stationary equipment. It is convenient for home or in a small workshop .

Most of the work can be done using a manual jointer. This can be attributed to the following points:

- The device is easy to use.

- It is possible to carry out the processing of various surfaces.

- The tool is inexpensive.

The desktop version can have a very different device, the choice is made by a specialist, depending on what work should be done.

Electric joiner tool

Today the stationary jointer can be made in the electric version. Professional devices are characterized by the following features:

- Quite a lot of weight and downforce.

- When working, you can achieve high accuracy.

- Increased labor productivity.

- Often in the design provides the ability to quickly change knives.

- The electric jointer is used in industry and everyday life, the product is characterized by high performance characteristics.

- The only drawback in most cases is the high cost, as well as the significant cost of electricity.

Jointer or planer?

Similar to the names of the tools are understandable: both are designed to align the surface of the workpiece.

What is the difference between jointer and planer?

Planer and jointer differ in the principle and quality of work:

The plane performs the initial surface preparation. It removes the top layer of the thickness that the blade is tuned to.

Tool planing removes basic bumps, knolls, knots. The design of the planer includes a block and a knife.

There can be two cutting elements, then the second after the first removes thinner wood chips, leveling the surface. He doesn’t finish the turning of a planer .

Jointer – Variety of planer with improved design. It has a longer and heavier body, which allows the tool to more closely cling to the work surface. 2 blades are integrated in the tool, tuned to the finishing joint.

The work of stationary equipment is the same for both types: they remove the rough edge from the wood. But the essence is different:

- Jointer removes the layer from the board, makes the surface flat, the end edge the planer makes it perpendicular to the main one.

- To create strictly parallel product planes you need a thicknesser, but the equipment processes only previously aligned raw materials.

Jointer and planer work in conjunction: one prepares, the other – finally aligns. But this is the case with machine tools.

Manual and electric jointer evens the surface and edges clean, and the thicknesser is used to draw parallel lines to a given size.

What things to avoid when working with a jointer or planer?

- Do not cut any part where there are plug knots, cracks, defects or foreign bodies (e.g., metal, stone).

- Do not leave the machine running unattended. Turn off the power and make sure that the tool holder has stopped turning before leaving the area.

- Do not make cuts more than 0.3 cm (1/16 inch) deep per pass.

- Do not make edges on workpieces that are less than 30 cm (12 in.) Long, 2 cm (3/4 in.) Wide and 0.6 cm (1/4 in.) Thick.

- Do not plan the surface of parts that are less than 30 cm (12 in.) In length, less than 2 cm (3/4 in.) Or more than 15 cm (6 in.) In width and less than 1.5 cm (5 in.) / 8 in.) Thick.

- Do not put your hands near or over the tool holder.

- Do not remove dust or wood particles from the tray with your hands or with compressed air. Use a piece of wood or a brush.

- Do not wear loose clothing, work gloves, tie, ring, bracelet or other jewelry that can get caught in moving parts.

How to choose the best jointer?

Having your own jointer, whether you are a professional handyman, a carpenter by trade or only in the shoes of a simple user is suitable.

But what to do given the number of models and brands that exist, and the promotions that are raining everywhere, the choice becomes difficult.

To do this, you have to trust yourself by considering the following:

- Know the use of the device: occasional or professional

- The power of the machine: a power less than 1600 W is more than enough for a device intended for occasional use.

- The quality of the machine: for this criterion, the opinion of specialists is highly recommended

- The price.