How do I Choose a Blade for my Miter Saw?

You’ve found the right miter saw for your job and can’t wait to get started.But before plugging in, you also need to think about the saw blade you are going to use. So how do I choose the right blade for my miter saw?

The blade of a miter saw is the most important part of this tool. Here are a few things to check before choosing a miter saw blade.

The material, the number of teeth and the thickness of the saw blade have a big influence on the final result.

You want beautiful planks for your gangway or your palisade, but you don’t want to spend too much time cutting out materials that should not be beautiful, but above all functional.

In this article, I explain what you need to pay attention when you choose the right blade for miter saw.

Choosing a saw blade according to use

Choosing a miter saw blade means identifying:

- the materials to be cut – wood, non-ferrous materials, plastic – determine the plate ;

- the type of tooth – relative to the material cut and the type of cut desired – and the step , the greater the space of the step, the more the is preferred;

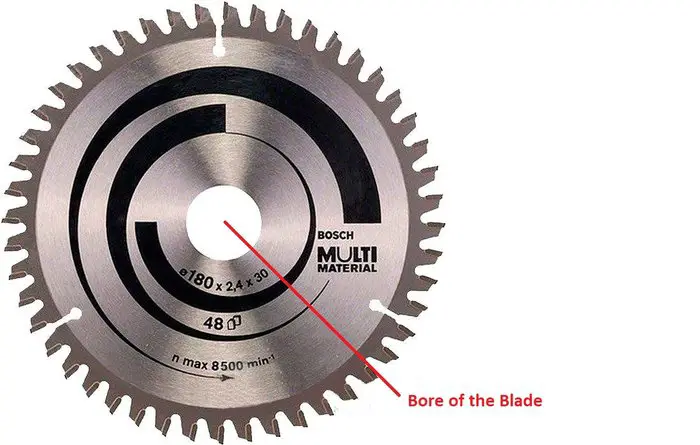

- the bore in millimetres (mm), or the diameter of the hole in the center of the blade, which can be reduced thanks to reduction rings ;

- the thickness of the blade in mm;

- the required cutting depth is indicated by the blade diameter as a function of the circular saw;

- the materials of the blade (the body) and the plate – depending on the materials cut, cf. The materials of the saw blades and plates;

- the number of teeth – the higher the number, the better the finish – indicated with the letter Z ;

- the number of revolutions / minute allowed ( rpm / rpm) relative to the diameter of the blade – to be checked together with the performance of the circular saw.

What are the criteria you choose the blade to be mounted on the miter saw?

The diameter of the blade

The diameter of the blade of your miter saw will determine the depth of your cuts. There is only one limit to the choice of blade diameter: the maximum diameter supported by your saw.

Otherwise you can fix a small diameter blade on your saw if you are used to working on not very thick objects.

You should know that the larger the diameter, the smaller the number of revolutions per minute of the saw.

Tips for choosing the right saw blade

As already described above, there is a differentiation between CV and HM saw blades . You should always buy a HM saw blade for the miter saw.

Saw blades are very important. Do not save money when buying a saw blade and invest a few dollars more. With the miter saw, it is recommended to buy a model cheaper and preferably to buy a noble blade for sawing.

The diameter and the bore of the saw blade must also match the cross-cut saw. Insert washers, etc. are not recommended.

What material do you want saw blade to be made of?

When choosing a saw blade, consider the materials you are going to saw.

Each type of material has a different structure which requires its “own” saw blade in terms of hardness, number of teeth or thickness.

You can imagine that solid hardwood requires a harder and better saw blade than chipboard.

For harder materials, you need a saw blade with fewer teeth than for less hard materials.

Are you planning to saw aluminum, laminate and plastic and do not want to use different saw blades for each material? Then opt for a universal saw blade.

Choose the right materials of saw blades and pellets:

| Abbreviation | Material | Use |

| VS | Carbide | Clean and precise cuts. Softwood, hardwood, chipboard, non-ferrous metal profiles, plastic, unchanged plexiglass sheet. Intensive use. |

| C1, C2, C3, C4 | Carbide 1, Carbide 2, Carbide 3, Carbide 4 | Hardness of carbide teeth; the higher the number, the more resistant the carbide (stays sharp longer but is more fragile). |

| CT or TCT | Tungsten Carbide or Treated Tungsten Carbide | Ideal for hard, soft, chipboard and composite materials. Regular use. |

| KC | Chromium | Cutting of the coating of bilaminated panels, MDF. Intensive use |

| HW | Uncoated cemented carbide | Body of the blade, does not include the pads on the teeth. |

| AHC | High carbon steel | High carbon steel; softer steel suitable for cutting wood. |

Choose the saw blade cut: rough or precise?

The number of teeth on a saw blade has a big influence on the type of cut.

The basic principle is as follows: with a saw blade with few teeth, you work quickly and make rough cuts.

If your saw blade has many teeth, your cuts are cleaner and more precise. To cut beams for construction, a rough cut is enough and you can use a 24-tooth saw blade.

But if you’re making a table, bookcase or cutting custom laminate, the finish should be clean and free of splinters.

It is therefore better to opt for a saw blade with 48 or even 72 teeth. Make sure that at least 3 teeth are in the material during sawing. If there is less, adjust the depth of the miter saw until it is.

How deep and how wide do you want to saw?

The cutting depth depends on the thickness of the material. For plinths or jambs, a maximum cutting depth of 65 millimetres is sufficient.

But if you want to cut spruce beams, you need more depth. In this case, you need a miter saw with which you can use a large saw blade, with a diameter of about 250 millimetres for example.

You normally penetrate deeper into the material than with a 210 millimetre saw blade.

A miter saw is only suitable for one specific size of blade, so it is not possible to use different sizes. The maximum cutting width is also fixed by miter saw. Here too, the larger the saw blade.

What size should the bore of the blade be?

The bore is the small hole found in the middle of the blade. It is through this hole that we manage to fix the blade on the miter saw. You must therefore ensure that the diameter of the hole is suitable for your miter saw.

A miter saw has a fixed attachment size for the saw blade. If this size is 30 millimetres, you should opt for a saw blade with a bore of the same size.

This is the hole in the middle of the saw blade. If the size is not the same, the saw blade will not fit your miter saw.

There are also saw blades with reduction rings. You can then adapt a 30 mm bore for smaller diameters, for example 16, 20 or 25.4 mm.

The blade is therefore suitable for your miter saw and you do not have to buy new ones.

Bore and diameter of the blade: the imperatives

A blade is a toothed metal disc with a hole in the center which is called a bore . It is through this hole that the blade is fixed to the saw.

The blade we are talking about is nothing more than a toothed metal disc with a hole in the center called a bore.

Through this hole, the blade is fixed to the circular saw. Be careful because, if you choose a blade with a larger bore diameter than that of your saw, you will have to mount it with an adapter ring.

You can choose a blade with a larger bore diameter than that of your saw, provided you mount it with an adapter ring and that the diameter of the bore is at least 5 mm less than that of the flange that secures the blade on the tree. This of course for security reasons.

You need to choose a blade whose diameter does not exceed the maximum diameter of the blades that can be mounted on your miter saw .

Choosing a slightly smaller blade is not dangerous, you will simply have a lower maximum cutting depth . If in doubt, read the instructions of your saw or check its dimensions on the blade already mounted.

The number of blade teeth

Contrary to what one might think, a miter saw blade is not a disc with perfectly circular edges.

They are rather accessories with serrated edges and these are the teeth that are responsible for cutting your materials.

The number of teeth will determine the quality and sharpness of the cut. The more teeth a miter saw blade has, the sharper the cut.

Choosing of miter saw blades according to the number of teeth

Below is a very, very rough indication of which materials can be cut according to the number of teeth:

- Up to 25 teeth : rough cut of the wood along the grain

- From 28 to 40 teeth : transverse cutting of the wood

- From 40 to 80 teeth : cutting of wood, plastic, aluminum and laminate

Consider that in addition to the type of material you must also consider the thickness .

In the case of wood, a general indication could be to choose a 24 tooth blade for large thicknesses (50/75 mm), a 40/60 tooth blade for smaller thicknesses.

As you have understood by now, it is always possible, indeed sometimes appropriate if not essential, to change the blade supplied with your miter saw: on the market there are blades of all diameters and adaptable to all saws.

At the time of purchase, always think about the use you will make of your miter saw and based on that it assesses whether the blade supplied is suitable or not.

For finer and more precise work, e.g. for laying floors, you should choose a saw blade with twice the number of teeth.

For example, a saw blade with 72 teeth would be a good choice. These saw blades are also recommended when working with harder materials.

Does the saw blade have to be of the same brand as the miter saw?

No, it is not mandatory. A Kreator saw blade fits perfectly with a Metabo miter saw.

There is obviously a difference in quality between the brands. A 20 dolar saw blade is less suitable for cutting hard wood and will probably lose its edge faster than an 80 dolar saw blade under intensive use.

This is particularly related to the material of the saw blade. Note, however, that whatever the brand, a circular saw blade is not suitable for a miter saw and vice versa.

The angle of the teeth differs from one saw to another, because the saw blade of a miter saw pushes the work piece towards the table, while a circular saw somehow “pulls” the material up .

Blade material

The material from which the blade is made will determine the strength and life of the blade.

It is advisable to buy blades that you can use for a long time. The stainless steel blades for example are perfect. Not only are they strong but they are also rust resistant.

By checking each of these points, you can be sure to choose the best blade possible for your miter saw.

Here is an easy way to remove rust from saw blade in an easy way!

Teeth type

There are different types of teeth: anti-recoil teeth, trapezoid teeth, alternating bevel teeth, etc.

Trapezoidal teeth, for example, are capable of cutting into nails, hence its name as a nail punch.

Anti-kickback teeth are widely used for cutting wood. The alternating bevel teeth are versatile and are used to process different materials.

Conclusion

The selection of miter saw blades is quite large and it is probably not always easy to find the right blade with the right number of teeth for the right material.

Most of the time, however, the products are so well described and labeled (both in the hardware store and online) that it is no longer difficult to acquire.

When you choose a miter saw blade always pay attention to the following:

- number of teeth

- material of the blade

- mounting of your miter saw

- cutting height

- diameter of the saw blade

- tooth position

- chip space as well as cutting width.

Now you know how to choose the right blade for your miter saw!