What is a Wood Planer? Easy Explanation (With Pictures)

The plane is a tool that has been around for more than 3000 years. It is mainly used for machining wood. You can use the plane to smooth, flat and straightens the wood surfaces. Here you can find out exactly what is a wood planer and how it works.

The wood planer or planer is a machine used to plan or flatten wooden surfaces providing powerful and precise removal of the material as well as a smoothing. It is made up of a frame which supports the rectangular work plane, this in turn is made up of two horizontal tables between which the knife-holder wood is located.

What is a Wood Planer?

A wood planer is a tool used to remove a layer of wood from a flat surface, straighten wood surfaces, smooth (finish) surfaces on both sides of the work piece.

The planer is a tool with which you can remove a layer of wood from a flat surface, you can straighten surfaces, you can smooth (finish) surfaces, you can be chamfered edges or you can make folds on doors. Not all these operations are done with the same planer, but in principle they are built the same way.

As we said, planers are hand tools and are used to flatten, roughen, face, smooth and level. With the correct movement, the tool is able to cut , flatten and straighten wooden structures, removing thin wood chips until the entire desired extension is aligned and without undulations or unevenness.

After use, fine sandpaper is recommended, which will prepare the piece for the application of finishes, such as varnish , paint and enamel .

The main element is a sharp metal blade and a body. The blade passes through the body through a slit called the mouth of the planer and reaches the wood.

By passing the planer over the wood, layers are taken from it, thicker or thinner depending on the position of the blade, the angle at which it is placed, the pressure exerted on the planer.

The planer for wood is a tool used to perform carpentry work aimed at smoothing the wood. Wood must be worked with sharp tools and this principle applies more than ever to planing with a wood planer.

Wood planers are designed for processing various types of wood. Often these machines are used after pre-processing the workpieces on a sawing machine.

Undoubtedly, the planer is a multifunction tool that will allow you to: perform high-precision operations on your parts with the possibility of calibrating them perfectly while making them completely flat.

The planing machines can be divided into table-top and freestanding machines by design. Bench-top machines are mainly intended for domestic use. The areas of application of such machines are small-scale production, subsidiary farming, private workshops.

Freestanding machines, with rare exceptions, belong to the professional class. Almost all machines have the option of connecting a chip suction unit as they generate a large amount of chips. The power of such machines is in the range of 1000-5500 W.

The machines are equipped with a parallel stop that can be tilted up to 45 degrees.

Often, planers have the following functions: maintaining constant speed under load, protection against voltage surges, soft start, thermal switch (overheating protection), magnetic starter, emergency stop button for the engine, chip evacuation system, anti-vibration system.

What is a Wood Planer made of ?

A manual plane consists of a sharp cutting blade or sharp metal plate attached to a solid body with a handle on top. The blade extends below the body and, as the tool passes over a wooden surface, it removes thin wood chips, smoothing the surface and reducing the thickness of the material.

Usually a planer is pulled away from the body, but Japanese planers are pulled towards the body. The blade is often adjustable to control the amount of material to be removed with each pass. Electrically powered wood planers, sometimes referred to as electric planers, are also available.

As a rule, a wood plane consists of a plane body, the underside of which the plane sole rests on the workpiece. The plane body has two handles by which it can be safely guided. It also contains the chip passage through which the wood chips are diverted upwards. Plane irons and planing knives do the actual planing work. Hand planes also contain a clamping device with which the plane iron is fixed.

Hand Planners components

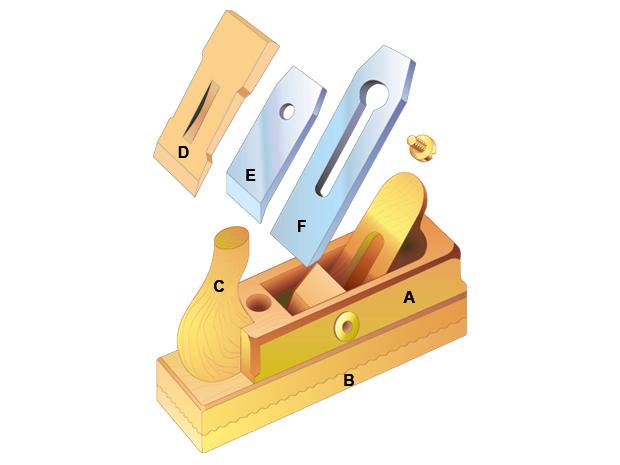

Structure of a simple double planer:

In the planer box A , which is usually provided with a harder underside (planer sole B ), the knife D screwed to the flap C is fastened with a wedge E. The left hand guides the plane with the help of the planer nose F .

The main components of the wood plane are:

- knife

- plane block

- wooden wedge.

The planer essentially consists of the following elements:

The planer box gives the planer its shape. It encloses the chip passage in which the plane iron (knife) made of hardened tool steel is. A wooden wedge clamps the plane iron in the plane case.

The plane sole is called the support plate of a wooden plane. It is exposed to strong friction during planing and is therefore made of hard-wearing material such as hornbeam.

The plane bodies were made from cast iron or tool steel very early on (cf. metal planes). A knob-shaped handle is located at the front end of the plane: the so-called plane nose.

Electric Planners components

Electric planners components:

- Rack or table

- Entrance placement table

- Exit table.

- Knife shaft.

- Height adjustment

- Stop ruler or guide.

The electric planer consists of the following main elements: knife shaft, motor, work table. The desktop is divided into two zones. A knife shaft passes between them and cuts off the lower part of the part. As a rule, workpieces are fed in manual mode.

An important criterion for processing parts is the number of knives provided by the machine. There are one, two, three or four knives. There are also shafts with many small removable knives. As a rule, these knives demonstrate high quality of workmanship, reliability, and also have a long service life.

Electric planers are frequently used by woodworkers and DIYers. They are used to make boards of the same thickness and for flat surface work. The technology developed with them makes it a highly appreciated tool by allowing you to work quickly and without as much effort as with conventional hand brushes.

Let’s see its characteristics:

- Flat bottom with a protruding rotating drum where sharp blades remove layers of wood.

- You just have to slide it over the surface of the material.

- Adjustable blades.

- They exist in various sizes. From the large 6 ½ inch wide models to the 3 ¼ inch wide models, which are the most popular.

What is a Wood Planer used for?

A carpentry tool such as the wood planer has many uses. Obviously, some such as smoothing or beveling have been with us all our lives, but it is no less true that new models with new applications are being developed.

Planing machines for wood are widely used in the production of various products: furniture, parquet, lumber, musical instruments, etc.

Some of uses of wood planners are:

- Match, smooth and grind various elements, from boards to doors, frames or wooden beams.

- Lowering of the heights of wooden pieces.

- Chamfering and grooving the wooden edges.

With the help of a planing machine, a person can:

- level the surface on large wooden blocks;

- trim the planes of the workpieces;

- select the grooves by the angular method;

- remove the edge.

In addition to these areas of application, the planer can be used for other woodworking operations.

| Advantages | Disadvantages |

|---|---|

| Essential to finish well the wood finishes | It must be handled with due precautions |

| Tool that we can take advantage of a lot | Many models that sometimes complicate the purchase decision |

| Most models are easy to operate |

Types of Wood Planer

Depending on the material and the desired result, you decide which type of plane you want to use. Planes can be divided into manual planes and electric planes, among other things .

Although the latter are now more widely used, both types have their advantages and disadvantages and are available in different designs.

Hand plane

Hand planes for manual work can have a body made of wood or metal. While metal is particularly robust, wood planes are usually better in the hand and have a more traditional look. The plane iron is made of tool steel.

There are a number of different types of hand planes. Which plane is best suited for what depends on the intended use.

These are the most common variants:

- Roughing plane: particularly high chip thickness; suitable when workpieces are to be planed thinner

- Raubank: for straight, even surfaces

- Double plane: suitable for small or narrow workpieces; Use instead of a robbery bench

- Finishing plane : for flat surfaces, small chip thicknesses up to 1 mm

- Smoothing plane: particularly thin chips, for cleaning veneers or solid wood

- Toothed planer: for targeted roughening of surfaces

In addition to these common types of planes, there are many other types of planes for specific purposes.

Electric planer

With the electric planer, the chip is removed by a cutting edge rotating horizontally and parallel to the workpiece surface . This is also known as a planer knife and is attached to the circumference of the drum-shaped planer shaft.

The planer shaft rotates at high speed and is moved against the direction of rotation over the workpiece or along the workpiece edge.

The plane has two soles. The height of the front plane sole is adjustable – so you can pre-select the desired chip thickness. Electric planers work at a fixed speed.

How high this is depends on the type of cutter, the speed is therefore predetermined by the design and cannot be changed. Planes with a one-knife cutter have a higher speed than planers with a two-cutter.

Depending on the type, the speed is electronically regulated and is then kept constant even with different loads.

Planer shafts with two knives have a larger diameter and a lower speed than planer shafts with only one knife. However, the peripheral speed is the same, so the quality of work and the work progress are comparable.

However, planes with only one knife can be made smaller and more manageable.

The electronic hand plane is a device for woodworking. The processing options for plastics depend heavily on the type of plastic in question. If possible, it is best to try out a piece of material beforehand to see whether the plane can be used on your workpiece.

The processing of metals leads to the destruction of the planer knives and damage to the device. You will need to use a special metal planing tool to do this .

How does a wood planer work?

Technically, both variants work in the same way. The plane iron, which guides the removed chips upwards, is located at the chip passage embedded in the plane body. The rest is pure muscle power.

A wooden planer is more comfortable to hold and its sole protects the surface of the material when planing. A metal plane, on the other hand, is almost indestructible and there is hardly any wear and tear even with frequent use.

A so-called double plane is always useful for furniture construction. In this model, which is typical for joiners and joiners, the knife is screwed to another knife called a flap. This flap breaks the chip, you achieve an even smoother surface when planing. For left-handers, planes with a suitably shaped horn are available.

We will focus on the electric wood planer, the most used by users. What you should know is that this model has some features that make it possible for you not to do as much force as with the manuals, while you finish the work before. Its operation is similar to any appliance, we will show you:

- Switched on. When turning on the brush, take the handle or grip. We leave the index finger on the on and off button and the thumb will be on the lock button.

- Security. When we press the safety button, it is removed and we can turn on the planer.

- Cables. The front plate must rest on the part we are working on, but without the cutting wheel contacting. The cable must always be away from the tool.

- Speed. We have to wait until we reach maximum speed. When the time came, we began to carefully push the brush forward. Do not forget to always use both hands to guide the planer.

- Horizontality In order for the recess to be even, the tool has to be kept horizontal while we brush, and press in the same way, increasing said pressure at the rear end.

Conclusion

To answer the question what is a planer we conclude that the plane is a classic and traditional tool in woodworking. The hand plane is an indispensable tool for woodworkers, joiners and ambitious craftsmen, especially when working on wood surfaces.

Wood planers are simple and convenient tools to use. An ally for DIY enthusiasts or professionals in the sector. In addition to their practicality, they are inexpensive. With an average budget, you can buy a good quality wood planer with adequate performance to carry out countless jobs.

For which applications is a hand plane used?

With hand planes, wooden surfaces are generously removed, precisely aligned or finely finalized. When finalizing, the focus is always on the cleanly smoothed surface , which brings out the character of the wood in every facet.

What material is a plane made of?

Planes are made of wood or metal:

- Wood planes: are lighter and enable less fatigue to work.

- Metal planes : run more smoothly due to their higher dead weight, which is particularly advantageous when the grain is difficult.

How does a wood plane work?

With a plane, the plane iron protrudes beyond the sole of the plane. The protruding cutting edge removes coarse to very fine chips from the wood surface. The thickness of the chip is determined with the protrusion.