Sandblasting Wood: All You Need to Know

A good solution for those who have old furniture and want a refurbishment, is to sandblast what they already have, using the sandblasting wood process.

The definition of sandblasting wood comprises the process by which, using pressurized air that involves abrasive matter, in the most possible and available ways, to sand and remove from the surface the upper surface.

Furniture restoration workshops can do real wonders when it comes to wooden furniture that you have in the house and not only.

Let’s look more into that!

What is Sandblasting?

Sandblasting or Abrasive blasting is the operation by which the metal surfaces are cleaned, smoothed or scratched using a sand jet sprayed with compressed air. It comes from French, from the word “sable” which means sand.

If it was initially used only for metals, with time the blasting began to be used also for wood, for removing paint and varnish from the older finished surfaces or for printing various signs with the help of templates.

How superficial, that is, the depth at which the surface layer is removed, depends on the pressure applied and the abrasive material used.

For sandblasting wood the method used, which has the most delicate effect, with the least dangerous and harmful effects, and then in increasing order of abrasion you can use shredded shells of walnut, or fragments of pumice stone.

That’s about the maximum recommended level to apply to wood, but depending on the strength of the wood, differentiated between resin and oak, the wood allows a harder treatment, for a more “aging” look.

Sandblasting Wood – what does it mean?

Sandblasting refers to the mechanical process that aims to remove residues from various surfaces. It can be about paint, rust, aspects that require a difficult removal, especially when the surfaces that exist are stone, metal, glass, and other solid materials, respectively.

The recommendation is to perform the sandblasting before the operation of priming, painting or others industrial operations. In doing the blasting,considered the use of abrasive particles, before cleaning.

For this purpose, compressed air is used, using specific equipment, equipped with hydraulic hoses, for blasting, anti static, made of special materials.

Regarding the abrasive materials that will be used to perform the specific operation, it may be about metal clippings, sand etc.

Sandblasting Wood and its Characteristics

- By definition, it refers to the cleaning action, which covers surfaces such as stone, metal, wood, etc. This is more than a manual job, an advanced level of cleaning.

- At the base of the process is the compressed air.

- Sand blasting is recommended for quick and efficient cleaning.

- Extensive material can be used, and the hose provided has specially adapted features. Sand is the most common. It is used as a substitute for water, but at an increased pressure.

- Made properly, the blasting has the modeling ability, being a solution even for engraving on stone or glass, wood also.

- It can be based on carbon ice, ensuring optimum hygiene.

- Cleaning of machinery, equipment or equipment of various types according to the standards, by reference to the need not to interrupt processes that would cause losses.

- It is also valid where you want to clean buildings, remove mold, glue, graffiti, oil and others.

Sandblasting Wood Furniture

Sandblasting is a sought-after process for cleaning old paint or finishing objects.

It is a difficult operation that requires a lot of attention from the worker because the safety rules used are very strict.

As an operation, sandblasting is performed on any surface only as the material abrasive is dedicated.

For wood, sandblasting is done without attacking the wood fiber, with granules that do not deform or dislodge wood fiber, therefore it is a gentle pickle without depth of very high penetration.

It is used especially on sculpted surfaces for removal as much as possible. This is not applied on structurally unstable surfaces or in the process of restoration of objects classified in cultural heritage.

It is a procedure used exclusively in the reconditioning of furniture or especially of wood in order to change color and to completely remove multiple layers of paint.

It is used only by trained and specialized personnel it is parked only in enclosures with special protective equipment (suit and full mask).

Attention to which companies you take the wooden objects for sandblasting. They are very high chances to irreversibly damage the wood material.

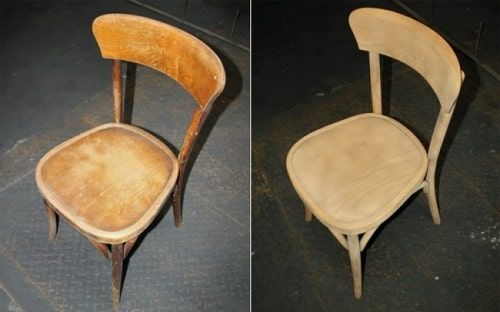

After a correct sandblasting, the furniture will return to the state it was before the varnishing and its color will be the natural color of the wood.

From this point before you decide how your furniture piece will be transformed to the end.

Even though the blasting was initially a process intended for cleaning wood surfaces and not only, it is currently used to make finishes inside a home.

Therefore, if you want a change in the house at the level of finishes then you can consider wall plating and sandblasting to get a completely natural, slightly rustic look with small industrial accents.

Types of sandblasting

These are the following types of sandblasting methods used:

- The mechanical sandblasting is mainly used on well-consolidated surfaces and without chromatic decorations, it is used when the paint layers are extremely thick and old.

- The variant of ultrasonic blasting with different characteristics of the device but with much safer and non-invasive results can be used.

- By mechanical blasting, a rather brutal process in working with wood, we can achieve good results in terms of cleaning time but losing meticulousness and proper control of pickling.

By blasting, the wood does not suffer deformation if the sandblasting technique is applied correctly.

Observing the working pressure and the granulation size of the abrasive material, blasting becomes a controllable and often efficient process.

Blasting can be part of the brutal pickling-cleaning operation, but it cannot be called a restoration process.

Depending on what we want to achieve, we can sometimes opt for sandblasting the old layers of paint and sometimes the lake adhering to sculptures and surfaces made of solid wood.

When you desired to opt for the application of the mechanical blasting operation of the wood, it is indicated to seek the advice of some specialists in the field of reconditioning / restoring the wood if the blasting is indicated on the respective piece.

It is not a method that can be easily used by anyone. It is practiced by specialists, because it involves the use of special pistols, under pressure.

During the operation, the sand and pieces of wood jump everywhere, and the sandblaster must wear protective equipment.

Do you know how a sandblaster works? If not then check this article!

Due to the fine sand present everywhere, the air must be filtered. Such activity is carried out in special spaces – cabins.

Sandblasting of Wooden Surfaces

Cleaning wood surfaces such as floors, panels or furniture is quite a difficult task. Cleaning dust or moping these surfaces is not enough to clean them, nor to give them a quality finish.

Wood blasting is essential in maintaining clean, elegant and practical working or living spaces.

Not only does this process smooth the wood surface, but it also gives it a shine, making it look cooler and look like new.

Whether it’s the wooden floors, the parquet, the wooden furniture, the wooden upholstery or the wooden bench from the outside, a good emerald can do all the best for all the areas involved.

However, there is also the solution of calling a specialist.

Sandblasting Wood Equipment

In general, the sandblasting equipment is composed of :

- compressor

- sand tank (or other materials used for blasting)

- a long hose that allows movement around the object to be blasted

- the gun and the nozzle (of various shapes and sizes, depending on purpose).

The bigger the compressor the longer you’ll sandblast before stopping, while expecting the compressor to catch up, so it is recommended to use a 7 to 10 hp compressor. With this one you can blast uninterrupted for about half a hour.

When using a bigger compressor it is recommended to use a bigger air tank (up to 110 gallons) so you can blast for a longer time.

The only drawback is that will take time for the compressor to fill up again the bigger air tank.

You can extend your blasting time by going to smaller nozzles but that will result in smaller areas being covered.

Other abrasive materials can be used not only sand (silicates). The least aggressive material, initially used for blasting copper, is baking soda (sodium bicarbonate).

It is used to clean wood, not to structure it. Due to the action with bicarbonate, the wood remains clean and fiber unpolished.

For structuring, more aggressive materials are used, such as sand, natural materials (walnut shells, coconuts, shredded corn chips).

Being an abrasive material, the granulation of the sand is also expressed in numbers, as in abrasive paper.

Also, small numbers mean big, coarse grains, and big numbers are fine grains.

The sand is found with grains between 30 and 220, but for wood it is recommended that with grains between 30 and 80.

Sandblasting Safety!

Over time, it has been found that the use of quartz sand in blasting has led to a large number of lung diseases and deaths among operators, as a result of silicosis diseases.

Silicosis is a deadly, non-healing disease that is caused by exposure to crystalline free silicon dioxide, particles found in dust generated during blasting operations with quartz sand.

The quartz sand used for blasting operations is particularly dangerous even when the workers wear protective equipment.

A very good alternative is the red garnet which for blasting is a highly efficient, environmentally friendly and non-toxic abrasive material (free silicates content less than 0.1%).

Due to the high hardness, about 8 on the Mohs scale, the red garnet has a high productivity in the blasting processes, is chemically stable, does not impregnate the blasted surfaces.

It can be used successfully, including in blasting materials that do not allow ferrous contamination, such as: stainless steel, aluminum, copper surfaces.

In addition to the use of non-toxic and environmentally friendly blasting agents, the risks of lung disease are reduced by the use of protective equipment in accordance with the provisions in the field.

Choosing a certified blasting hood is of major importance to the health of operators.

Thus, a blasting helmet compliant with the provisions issued by OSHA (US) and / or ANSI provides high impact protection against noise and dust that is formed during blasting.

At the same time, an optimal blasting helmet should evenly distribute the weight on the shoulders so as not to put pressure on the operators neck, to allow the free movement of the head during work, good visibility during blasting operations through the observation window and heating or cooling the air breathing.

Can I sandblast Wood?

Yes, you can sandblast wood and sandblasting is a skill learned thru practice. This process involves manual sanding using the appropriate brush or grinder by rubbing the wood surface to improve its quality.

The sandpaper is a kind of hard paper with an abrasive material applied over it.

This method is preferred for small and medium pieces of furniture through the house or for smoothing the floors and offering a shining look to them.

Those who work with this process need a protective equipment similar to the divers, and the air or oxygen tube is not a mess, because near the spray area, the air is very difficult to breathe, but I refer to the power machines, those for more domestic applications they are easy to use without many precautions.

The advantage of Sandblasting Wood Surfaces

The sandblasting process involves several advantages besides smoothing the wood surfaces. Here are some important advantages in wood sandblasting:

- Sandblasting the wood upholstery gives the surface a glaze-like appearance, which gives the wood a special gloss and gloss.

- It also removes traces of wood chemicals that are present there as a result of chemical treatment for the manufacture of wood parts.

- Blasting also helps to close the wood pores by pushing the fibers back into the wood.

- It also improves the quality of rough surfaces because it straightens the small cracks on the wood and smooths them.

- Allows the use of a wide variety of abrasive materials.

- Provides flexibility in terms of wetting pressure.

- Does not affect hardwood. If the pressure is adjusted, it is effective even on soft woods, without accentuated wear.

- Many people choose wet sandblasting to restore old wood furniture, wooden constructions or bridges, benches and other items.

Conclusion

Dust-free sandblasting is therefore a very good solution for more aesthetically pleasing wood elements. This solution greatly increases the lifetime of a piece of furniture or construction, leading to substantial long-term savings.

After blasting, wood is obtained with the structured surface, meaning the late wood is highlighted by removing the early wood.

The process is very much applied to the wood of resin and oak or similar essences.

Depending on the granulation of the material used in sandblasting, we obtain more accentuated or discrete structured surfaces. After blasting, a lot of broken fibers appear which can remove water.

As a result, after sandblasting, the wood must be sanded and finished to prevent water loss.

RECOMMENDED READING: