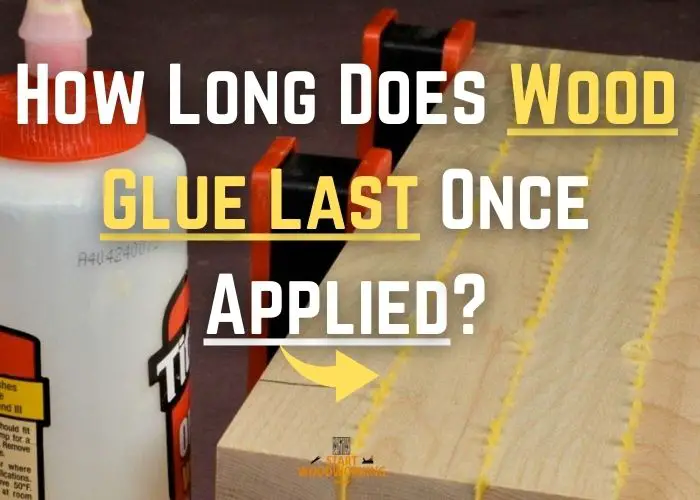

Durability Guide: How Long Does Wood Glue Last Once Applied?

In my extensive experience with woodworking projects, one question that often surfaces among enthusiasts and professionals alike is regarding the longevity of wood adhesive after it has been applied.

Wood glue bonds typically last:

- Interior furniture – 20+ years with PVA glues like Titebond I/II. Epoxy may outlast the wood.

- Outdoor structures – 5-10 years for PVA, 10-15 years with waterproof formulas like Titebond III. Epoxy provides 10-15 years longevity.

- Remodeling projects – 10-15 years for standard PVA indoors. Epoxy or construction adhesives ensure 15+ years.

| Glue Type | Shelf Life | Furniture Durability | Outdoor Durability | Remodeling Durability |

|---|---|---|---|---|

| Titebond Original | 1-2 years | Excellent, 20+ years | Good, 5-10 years | Very Good, 10-15 years |

| Titebond II | 1-2 years | Excellent, 20+ years | Good, 5-10 years | Very Good, 10-15 years |

| Titebond III | 1-2 years | Excellent, 20+ years | Very Good, 10-15 years | Great for wet areas 15+ years |

| Gorilla Glue | 1-2 years | Very Good, 15-20 years | Fair, 2-5 years | Good, 5-10 years |

| Elmer’s Wood Glue | 1-2 years | Good, 10-15 years | Poor, <2 years | Good, 5-10 years |

| Liquid Nails Heavy Duty | 6-12 months | N/A | Very Good, 10-15 years | Recommended for remodeling |

| Weldbond | 1 year | Excellent, 20+ years | Fair, 2-5 years | Good, 5-10 years |

| Epoxy | 1-2 years | Excellent, 20+ years | Very Good, 10-15 years | Excellent, 15+ years |

Keeping wood glue in optimal conditions before using it is a key factor that contributes to the adhesive retaining its properties once applied. This ensures that the integrity of the bond will remain strong over time.

While it’s challenging to pinpoint an exact expiration date post-application, my experience and observations support the notion that wood glue can remain effective for several years.

If the adhesive was stored correctly and applied following the manufacturer’s guidelines, it supports the creation of durable, lasting connections in woodworking projects.

Manufacturer’s Guidelines vs. Real-World Usage

Although manufacturers often state a shelf life of one to two years, I’ve seen PVA-based glues remain viable well past these conservative estimates. It is a testament to the fact that with the right adhesive storage conditions, these products can defy the printed expiration dates.

My tried-and-true approach? A steadfast commitment to a cool, dry storage setting, thereby circumventing the extreme temperature variations that would otherwise spell doom for my stocked adhesives.

| Storage Factor | Optimal Condition | Result if Maintained |

|---|---|---|

| Temperature | Cool and consistent | Prevents premature chemical breakdown |

| Moisture | Dry environment | Inhibits mold growth and water-induced spoilage |

| Air Exposure | Airtight seal | Limits oxidation and extends shelf life |

I assert that when these conditions are met, the real-world performance of wood glue can surpass the expected lifespan, sometimes by a significant margin.

Signs Your Wood Glue Is Nearing the End of Its Useful Life

1. Changes in Consistency and Texture

One of the first symptoms that caught my attention was a change in the glue’s consistency. An optimal adhesive should be smooth and easy to apply.

When I detect that the texture has thickened deeply, becoming stringy or pasty, it’s clear that the adhesive consistency changes suggest the glue is no longer at its best.

Similarly, if lumps or gels appear that do not smooth out upon stirring, this is a strong indication of an expired wood glue identification.

2. Altered Coloration and Odor

Another sign I look for is a change in coloration. A reliable adhesive like Titebond II is characteristically a certain hue when fresh. If I notice it turning a shade of orange, for instance, that’s a strong visual cue of degradation.

Likewise, an uncharacteristic odor—whether it’s a sour or rancid smell—often reveals that a glue has expired and may no longer be effective.

3. Weakened Bonding Power

To further assess the quality, I occasionally perform performance tests, which involve applying a small amount of glue to a test piece of wood to observe bond strength firsthand.

If the results are underwhelming, it may be time to part ways with the current bottle and invest in a fresh supply to guarantee the success of future adhesive applications.

Maximizing the Usable Life of Your Wood Glue

As a committed craftsman, I’ve discovered that the key to optimizing wood adhesive longevity lies in meticulous storage and preservation.

To safeguard the viscosity and reliability of my adhesives, I follow a set of guidelines that maintain each product’s effectiveness well beyond the expected time frames.

Effective Storage Techniques

- I ensure my wood glue is kept in a place that remains consistently cool and dry. Significant temperature swings, especially those found in unregulated workshop environments, are detrimental to the chemical stability of wood adhesives, so climate control is essential.

- For partial bottles of glue left over from projects, I transfer them to small sealed glass jars. This way I use up the leftovers within a couple of months while sealing out the air. Less waste that way.

- Additionally, I verify the seal of the container is airtight after each use, shielding the contents from air and moisture that can precipitate a premature chemical reaction.

Practices to Prevent Premature Expiration

One practice I find particularly effective is labeling each bottle with the date of purchase. This habit assists me in implementing a first-in, first-out rotation system, which I combine with visual and physical inspection cues to assess usability.

I organize my glue collection by the date opened and then use the older bottles before they expire. Following the FIFO principle( for first in, first out) maximizes the shelf life of each bottle.

Furthermore, if my wood glue begins to thicken, a minimal addition of water can sometimes rejuvenate it, restoring its original consistency.

However, I apply this practice sparingly, as altering the formula can potentially impact the glue’s strength. With these wood glue storage tips, I effectively extend the life of my adhesives, making my woodworking projects both durable and dependable.

Differences Between PVA, Polyurethane, and Other Glue Types

Having used an array of adhesives, I’ve observed that PVA glues are beloved in the woodworking community for their long-term usability and resilience. PVA is a water-based adhesive and under ideal storage conditions, it can maintain its efficacy well beyond its stated expiration date.

This is quite the contrary when it comes to PVA versus polyurethane glue. Polyurethane, often required for its waterproof properties and strong bond strength, does not share the same generous longevity due to its moisture-sensitive nature.

| Glue Type | Base | Water Resistance | Shelf Life | Sensitivity to Moisture | Usage Considerations |

|---|---|---|---|---|---|

| PVA Glue | Water | Limited | Years past expiration if properly stored | Low | Needs to be kept in cool, dry conditions to prevent spoilage |

| Polyurethane Glue | Chemical | High | Shorter, if not precisely maintained | High – cures with air moisture | Storage requires expulsion of all air and prevention of moisture ingress |

The longevity of polyurethane glues is heavily dependent on keeping them sealed from the air and moisture. Any negligence in storage can lead to the glue curing within the bottle itself, defeating its purpose before ever being applied.

Thus, when advising others, I always emphasize the careful consideration of the adhesion requirements of their project and the critical nature of glue storage.

Renewing and Salvaging Aging Wood Glue

I’ve been faced with the dilemma of whether to revive an old bottle of wood glue or simply replace it. Through experience, I’ve learned when it’s feasible and advantageous to rejuvenate wood glue, as opposed to discarding it in favor of a new adhesive. Both methods have their place in the workshop, the decision largely rests on the condition of the glue in question.

When to Rejuvenate vs. When to Replace

If the glue has separated into layers or shows evident clumps, it’s a sign that you’re better off replacing it rather than attempting a revival. You should only consider rejuvenating wood glue if it has slightly thickened but remains homogenous without any signs of particle formation.

How to Properly Mix and Revive Old Glue

When I’ve decided to revive an adhesive, I do it with extreme care. The key to properly reviving old glue is adding a small amount of water—just enough to reattain its original viscosity.

Here are my steps to properly mix and revive old wood glue:

- I first check the expiration date on the glue bottle. Most glues only last 1-2 years after opening, so if it’s past the date, the glue has likely dried out too much to be revived.

- I scrape off any dried glue that has accumulated on the lid and rim of the bottle. Getting a clean mixture is important.

- Then, I add a small amount of water, usually around 5-10% of the total volume. Too much water will weaken the bond, so I go slowly.

- For epoxy or polyurethane glues, I use acetone instead of water since it does a better job of dissolving any dried particles. But I only use it sparingly.

- I seal the bottle tight and vigorously shake it for 2-3 minutes. This helps break up any dried chunks and mix them back into the liquid.

- After shaking, I let the glue sit for 30 minutes before checking the consistency. It should be smooth and thin enough to pour easily.

- If it’s still lumpy, I add a tiny bit more water, shaking well in between. I’m careful not to make the glue too runny.

- Finally, I test the revived glue on scrap wood, letting it fully cure before pulling apart to check the bond strength. If it’s still weak, I discard the glue and use a fresh batch instead.

- Proper mixing takes patience but reviving old glue can work if done correctly. Of course, nothing beats using a new bottle when possible.

The critical step is to mix thoroughly, ensuring that the water is fully integrated. For this, a robust stirring stick and a keen eye for consistency are indispensable.

Assessing Bond Strength and Performance of Aged Glue

Let’s delve into the methods I use for identifying potential weak bonds and points of failure that could compromise the structural integrity of finished projects.

Conducting Tests on Glued Joints

I put aged glue to the test by applying it to a sample joint and monitoring how it performs under stress. This real-world assessment helps me gauge the current strength of the bond.

It’s a practical approach that offers a clear perspective on whether the aged glue can still meet my woodworking standards.

Identifying Weak Bonds and Potential Failure Points

Detecting and addressing any underperformance in glued joints is crucial. I meticulously inspect each bond, probing for any signs that could indicate weakened adhesion.

Through these careful evaluations, I can determine whether the glue still has the capacity to hold a project together securely, or if it’s time for a replacement using the table below:

| Type of Wood Glue | Performance After 1 Year | Performance After 5 Years | Performance After 10 Years |

|---|---|---|---|

| PVA Glue | Excellent | Good | Fair |

| Polyurethane Glue | Good | Fair | Poor |

| Epoxy | Excellent | Excellent | Good |

https://www.gorillatough.com/faq

https://www.westsystem.com/ss/epoxy-shelf-life/

The durability of wood glue in your woodworking projects depends on various factors such as the type of glue used, storage conditions prior to application, and environmental factors during and after the application. Proper storage and application can significantly increase a glue’s lifespan, maintaining its strength for several years.

Factors that affect the shelf life of wood glue include storage temperature, exposure to moisture, and whether the container is well-sealed. To maximize the shelf life, store your wood adhesive in a cool, dry place, tightly sealed and away from direct sunlight.

To assess the effectiveness of applied wood glue, look for signs of a solid bond in the joints of your woodworking projects. If the bond remains strong without signs of cracking or weakening, the glue is likely still effective.

While manufacturers provide guidelines for an expiration date, often one to two years, with proper storage, PVA wood glue in particular can last much longer, even up to a decade, without losing effectiveness.

Maximize the usable life of your wood glue by storing it correctly—in a cool, dry place at a consistent temperature, in an airtight container. Consider labeling the container with the purchase date to keep track of its age.

Leave a Reply