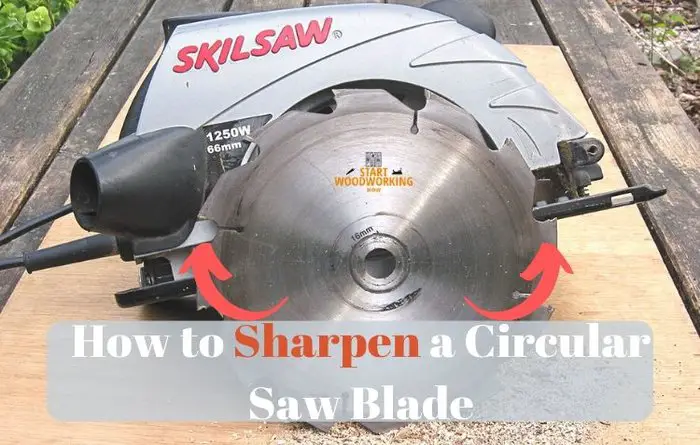

How to Sharpen a Circular Saw Blade[Step by Step]

In most cases, saw blades will be replaced rather than actually sharpened or even limited. Basically, it doesn’t hurt to know how to sharpen a circular saw blade. You don’t necessarily have to throw away circular saw blades if they have become blunt – this also saves costs and lengthy ordering of spare parts.

You can learn how to sharpen a circular saw blade following the instructions in this article.

How to Sharpen a Circular Saw Blade Step by Step

Before we start to sharpen the circular saw blade, the blade must be removed . Click here to see exactly how to remove a circular saw blade.

Be sure to turn off the power before you start working on your circular saw. Handheld and plunge saws often use a spindle lock , with which you can change the blade quickly.

These tools are used to sharpen circular saw blades

There are special grinding devices for sharpening circular saw blades. However, these are usually associated with relatively high acquisition costs and are generally not worthwhile for the hobby handyman.

Alternatively, you can sharpen by hand old circular saw blades. Here you can get by with just a few tools. You will need:

- a ring spanner

- two screw clamps

- a flat file

- a set of pliers

- a triangular file

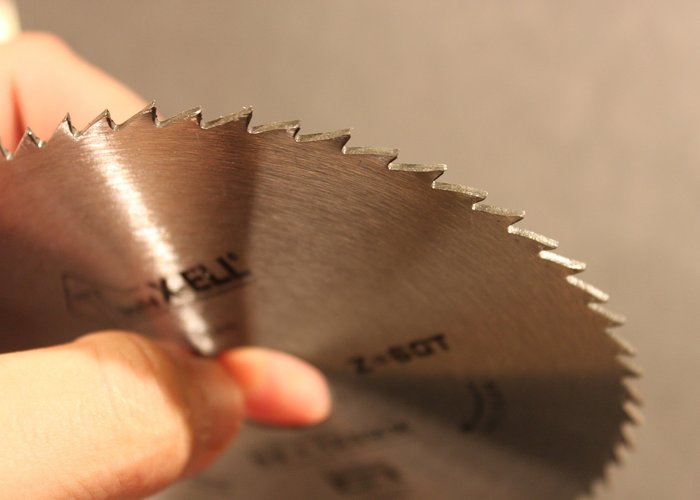

However, the manual sharpening of the circular saw blade only works with saw blades whose teeth have not been specially hardened.

Because blades that have been provided with hard metal are just as hard as the files that are used for processing and cannot be shaped with them.

For saw blades with carbide tips , a special sharpening device must be used, which, for example, has a professional grinding service.

The sharpening of circular saw blades is possible in just a few steps:

Step 1: Remove the saw blade

The saw blade must first be removed from the circular saw. To do this, loosen the nut with a clockwise turn using the ring spanner and safely remove the blade from the circular saw body.

Step 2: Fix the saw blade

The saw blade is fixed to the workbench for sharpening. This is done using the two screw clamps. Make sure that you clamp the blade strong that it later vibrates as little as possible when sharpening and that there are no disturbing vibrations.

Step 3: Make a Mark

Make a mark with the felt on the side of the blade, which will allow you to identify when you have sharpened all around the circular blade.

Then take your file, tilt it around 20 ° and file 4 times up and down along the bevel.

This will make it easier for you to find your way around the saw blade.

Repeat the sharpening and file the other side of the circular saw blade, so that the teeth are perfectly sharp.

Step 4: Trimmed the saw teeth of the circular saw

The teeth of the saw blade are trimmed before sharpening. This step is necessary because the originally straight row of teeth becomes uneven over time and through frequent use.

With the flat file the tooth tips are flattened and filed to the same height. This is done by repeated, horizontal file strokes over the rows of teeth.

Step 5: Set teeth

In order for the saw to be able to work properly again later and not to get caught in the workpiece, it needs set , i.e. mutually bent teeth .

This ensures a saw cut that is wider than the actual saw blade and prevents the material from getting stuck.

It is best to use a set of pliers for this . This helps to create a set that is evenly directed to the left and right, thus ensuring that the saw blade later works ideally in both directions.

Avoid bending a tooth that was originally set on the left to the right and vice versa, otherwise the teeth may break and the saw blade will become unusable.

Step 6: Sharpen the circular saw blade

Once the rows of teeth have been filed and the teeth set, the actual sharpening can begin. For this you use the triangular file .

With three to four filing strokes over each tooth, a uniformly pointed shape should be achieved so that all teeth later look identical.

Make sure not to remove too much material straight away, otherwise the other teeth will have to be adjusted again later.

It is advisable to first sharpen the left-hand tooth row, then turn the blade and then sharpen the right-hand tooth row.

Step 7: Install the newly sharpen circular saw blade

After sharpening, the saw blade can be reinstalled in the circular saw.

Pay attention to the correct, tight fit to avoid imbalance and thus a restless run of the blade. With the ring spanner, the nuts are tightened by turning them to the left.

Step 8: Test the resharpened circular saw blade

Snap check

After sharpening all the teeth, it is necessary to check the cutting properties. Fasten the equipment to the tool, turn on the power and saw a trial wooden block.

Indicators of quality sharpening is a light cut, smooth running, quiet operation. If there is loud noise and uneven cutting of the material, it is necessary to check the height of the teeth, perhaps it is not the same.

To align all cutting segments, raise the marker to the cutting edge and make a complete turn of the equipment in the direction opposite to the direction of rotation.

Inspect the surface: a mark should remain on each tooth to help compare the height of all segments. Find the teeth with the highest height and carefully reduce their length with a file.

Sharpening circular saw: by a pro or yourself?

Going through a pro does not incur very high costs.

The sharpener for circular saw is relatively expensive (around 600 $ for a table sharpener).

A specialist will sharpen your blade for less than $ 15.

The professional blade sharpening price varies according to the diameter and the number of teeth of the blade.

Here is an indication of the prices for sharpening carbide discs for circular saws:

| Diameter | Number of teeth | Price generally observed |

|---|---|---|

| 250 | 80 | Around 20 $. |

| 300 | 96 | Around 20 $. |

| 350 | 108 | Around 24 $. |

| 400 | 108 | Around 25 $. |

| 450 | 108 | Around 26 $. |

| 500 | 140 | Around 38$. |

| 600 | 144 | Around 40 $. |

How do I know if my circular saw blade is dull?

The saw blade rotates more slowly and therefore makes less progress in the workpiece.

You can recognize a blunt circular saw blade by these signs:

- Blade making only slow progress and turns slowly.

- Your circular saw suddenly generates unusual vibrations

- A poorer cut or frayed cut edges

- Instead of sawdust, the duller teeth produce finer sawdust

- Interfaces charred and start smoking because the saw blade rubs too hard

Broken or broken teeth are even more evident. This happens when a circular saw blade hits a nail or other metal. In this case, it is worth buying a new saw blade.

If your saw blade is “only” blunt, then re-sharpening your circular saw blade is worthwhile. There are various ways to do this. You can sharpen the saw blade yourself in various ways, or have the work done by a professional.

Maybe you decide you want a saw and don’t know which type of saw to get. I have written an in depth comparison between Circular saw vs. Miter saw here.

How much does it cost to sharpen a saw blade?

Is it worth sharpening circular saw blades?

With many tools, of course, the question arises whether sharpening the circular saw blade is actually worthwhile. In this article you will find out which prices you have to calculate when you sharpen circular saw blades and which price differences there are.

Prices

The prices can be very different. Traditional tool grinding shops often require more to sharpen a circular saw blade than a new one would cost. Prices of 20 – 30 Dollars for grinding are quite common.

The prices for online grinding shops are often quite high, depending on the number of teeth on the saw blade. Offers between 8 and 10 Dollars for a circular saw blade are also available (plus shipping costs, mostly return shipping).

Even at on-site grinders, you always have to take into account the costs (travel costs) for the take-in and pick-up, as well as sometimes the time required.

Price differences

In some cases, prices are also calculated on a different basis – for example, per tooth of the saw blade (around $.80 per in./ per tooth, if this is calculated). This also explains the price differences when grinding different saw blades

Reasons for the price

Professional grinding machines are very expensive (some devices cost almost $ 200,000). The grinding wheels used for grinding are mostly diamond wheels, which are also very expensive and wear out over time.

Do you know that are over 32 types of saws? Click here to see this huge list of saws.

How to sharpen a circular saw blade with a dremel

You certainly know the small Dremel multi-function grinder. The practical hand tools can be equipped with all kinds of attachments so that you can use them for sawing or grinding, for example.

So it makes sense to sharpen saw blades with the Dremel. When sharpening the circular saw blade with the Dremel, it is difficult to always maintain the correct grinding angle without tools.

Either you have a lot of experience and a steady hand, or you need a suitable device for clamping.

Incidentally, a suitable attachment from Dremel is available for sharpening saw chains for the chain saw, which considerably simplifies this work. Perfect if you want to sharpen your chainsaw.

What is the hook angle on a circular saw blade?

The teeth of a circular saw are sharpened taking into account the four main angles that are formed at the intersection of the planes:

- rake angle;

- rear corner;

- bevel angle of the front

- rear levels.

The sharpening angle is also taken into account as an aid ,which is given by the value of the front and back corners.

The sharpening angles depend on the intended use of the saw:

- a rake angle of 15 to 20 degrees is suitable for rip sawing;

- with cross saws – from 5 to 10 degrees;

- for universal use an average of 15 degrees.

When to sharpen a circular saw blade?

There are definitely certain signs by which you can judge the condition of the circular saw blade.

Sharpening of the circular saw blade is necessary when the following situation occurs:

- During operation, smoke arises, the specific smell of burning wood, the casing covering the teeth of the saw starts to heat up quickly.

- When moving the tool along the workpiece, considerable effort must be applied, as if to push the saw forward.

- After cutting the material and visual inspection of the sawn edge, black soot or many chips, fiber burrs, and chipped areas are visible.

- With a careful examination of the saw teeth in a magnifying glass, you can see that the cutting parts have not sharp, but rounded edges.

Conclusion

In many cases, independent, manual sharpening of saw blades is worthwhile, because it saves resources as well as money.

Repeated sharpening is possible without any problems, especially with unhardened sawing blades .

The worn saw blade is made ready for use again in just a few steps, and safe and flawless functionality is guaranteed. A double grinder with the appropriate grinding wheels can accelerate the grinding work.

If the other side is a saw blade with hardened tips, manual reworking is not possible.

But here, too, it is not necessary to buy a new one: special sharpeners also help here. A new saw blade is ultimately required if the old one has worn out too far or if it shows excessive damage.

How to sharpen a circular saw blade with a file

If you have a diamond file, here are the steps to sharpen the blade:

First, you need to remove the blade.

Generally circular saws have a system to remove the blade in complete protection.

For older models, you will need a wrench to remove the bolts

Afterwards, it is preferable to hold the blade in a vice in order to carry out the sharpening .

Turn the teeth of the blade in front of you but do not over-tighten so as not to risk damaging it.

Then you need to make a mark with the felt on the sides of the blade.

This will make it easier for you to find your way around the blade.

Finally bring your file which you will tilt around at twenty degrees and file four times from top to bottom.

Do the same on the other side.

For the fourth step, you need to file the point of each tooth and then to finish, you will only have to put the blade in place since it is now very sharp.

You can reinstall it on the circular saw.

What are the methods of sharpening a circular saw blade?

Sharpening masters know how to sharpen a circular saw blade correctly.

The services of a specialist will provide a good result, but you will have to pay money.

Having special tools at hand, the procedure can be carried out independently.

Sharpening methods of a circular saw blade:

– circles for sharpening saws with a diamond abrasive;

– file for sharpening and vice for fixing the disk;

– a professional machine is expensive, but the result is the highest quality.