How to Sharpen a Table Saw Blade[Step by Step]

The sharpening of table saws is hardly carried out today, most saw blades can be easily exchanged. But earlier, when it was not easy to change the saw blades, sharpening was just as much a job as sawing. Even today, it can still make sense to know how to sharpen a table saw blade, for example to save some money.

We will explain exactly how to sharpen a table saw blade in this article. The sharpening itself is not as difficult as you might think.

How to Sharpen a Table Saw Blade Step By Step

A table saw is one among the most expensive woodworking tools, and unfortunately when they broke it is expensive to repair them.

There may come a time when you need to replace the table saw blades, but you can use it more if you sharpen the table saw blade yourself.

A dull table saw blade can not only ruin your work, but it can also be dangerous because the blade can cut wood and cause it to burst and fly on you or others.

Read this article which will show you how how you can sharpen your table saw blades step by step!

The sharpening of table saw blades is possible in just a few steps:

Step 1. Prepare the sharpening tools

Sharpening by hand requires only a few tools:

- a flat file

- a triangular file

- a set of pliers

- screw clamps

- a ring spanner

Step 2. Take the necessary safety precautions before you start sharpening

You should never sharpen your table saw blades with the blade attached to the table saw.

Choose a flat and safe surface where you can work, then remove the blade from the saw and place it on the flat surface.

Just because the table saw blades are not attached to the saw does not mean that they are safe. They are always sharp so be sure to wear your work gloves to sharpen and handle the table saw blades.

This can be a messy job, so make sure that you place a tarp on the floor where you are going to work and that you wear your goggles and face mask.

As you begin to sharpen the table saw blades, you will drop pieces of metal. These shards of metal and metal dust can become very slippery on a concrete or wood floor.

If the metal shavings get into your eyes, they can cause blindness and if you take them in your lungs you can choke and get very sick, so it is dangerous for your health.

Step 3. Sharpening the table saw blades

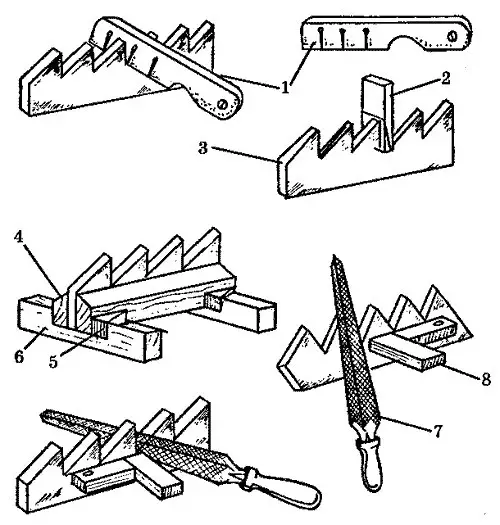

First the table saw blade to be sharpen must be clamped. You can use a filing clip, or if it is not available, a simple vice. Clamp a piece of wood between the table saw blade and the vice so that the table saw blade is not clamped directly into the vice. This will prevent any damage to the blade.

Of course, the teeth must face up. Make sure that they only protrude as far as is necessary for sharpening.

It can be an arduous process that does not need to be rushed. Use your sharpening file and start to sharpen the table saw blade.

Use strong back and forth strokes across the section. Take several minutes for each section of blade. Rotate the blade and continue sharpening until you are satisfied with the result.

Dressing

Start with the dressing. This means that the teeth of the table saw blade are all brought to a level so that they form a horizontal line.

To do this, use a simple flat file with which you rub evenly over the tooth tips until they are slightly flattened. The tips of the teeth are blunted. This is done until all teeth have the same length.

The sharpening

With the now flattened table saw teeth, of course, no clean cuts can be made. Therefore the teeth of the table saw must now be sharpened again. We are now using a so-called triangular file.

The tips are now sharpened until the flat surface disappears. More is not necessary and should not be refined.

You do the whole thing with each individual tooth. Make sure that the table saw teeth are sharpen evenly.

The closings

With some saw blades, the teeth do not only point in one direction, but alternately to the left and right. If this is the case and the teeth only protrude unevenly, then they must be cut off. A special set of pliers is used for this.

However, this process cannot be carried out on fine saws because the teeth on the blades are too fine and would be damaged by the pliers.

Sharpen saw teeth

Now we come to the actual sharpening process. The triangular file is the most important tool for this. If a cross-sectional saw is to be sharpened, the file must be placed diagonally and horizontally to the saw blade in the tooth gaps. In the case of rip saws, however, the file is placed at right angles and horizontally.

One table saw tooth after the other is sharpened. Use only light pressure and file each tooth over the same period to ensure uniformity.

If the saw is only lightly closed, the process of dressing, sharpening and cabinets can be omitted and the sharpening can be started directly.

Step 4. Lubrication and fixing

To keep your table saw blades sharp and free from rust, you need to lubricate them. Since the blade is freshly sharpened, you don’t need a lot of oil.

Press a small amount of lubricating oil over the entire blade, including the sharp edge. Take a bundle of newspaper and rub the oil into the blade.

Spread it out as much as you can and don’t worry if you remove some of the oil in the process. When you are done, replace the blade.

Step 5. Test the new sharpen table saw blade

Take a piece of wood and cut it into several pieces with the table saw to test the sharpness of the blade. You will know if the blade is sharp enough. If the blade is not as clean as you want, repeat the previous steps.

Maybe you want to change the blade of your circular saw! Click here to see how to change the circular saw blade in easy step by step instructions!

How do you know if a table saw blade is dull?

However, a saw blade is a so-called wearing part and must be replaced at regular intervals. In some cases, however, it is also possible to sharpen the saw blade.

The first signs of a dull saw blade:

- Saw blade rotates more slowly than usual

- Discolored or unclean interfaces

- Fine sawdust

- Very high or unusual noise

- strong vibration

A dull saw blade not only ensures poor cutting results, the risk of accidents also increases automatically. If your table saw shows a blunt saw blade, you should start to sharpen the blade or replace it.

A significant indicator of a dull saw blade is the appearance of heat marks on a workpiece. This increases the duration of the cut and the effort required to drive the saw blade into the workpiece also rise.

In addition, the corners are torn out and the result of the cut is unsatisfactory. The risk of jamming or recoil of the saw blade is increased. This creates a high risk of injury for you at the same time.

| Blade sharpening angle (°) |

| 15-25 ° (for longitudinal sawing/rip sawing) |

| 5-10 ° (for the transverse sawing) |

| 15 ° (for universal saw application) |

The front grinding angle not only determines the properties of the saw blade, but also its purpose:

- 15-25 ° – for rip sawing;

- 5-10 ° – for the transverse direction;

- within 15 ° – universal application.

The size of the angles is also determined by the hardness of the material to be cut – the higher it is, the less should be sharpened.

Sharpening angles are determined by the purpose of the saw, i.e. what cutting material and in which direction it is intended:

- Saws for longitudinal sawing have a relatively large rake angle (15 ° -25 °).

- For saws transverse sawing angle γ usually ranges from 5-10 °.

- Universal saws designed for transverse and longitudinal sawing have an average value of the rake angle, usually 15 °.

How do you sharpen a table saw blade at home?

You can sharpen the table saw blade at home and it is not at all necessary to have a special grinding machine in your workshop, which costs a lot of money and is used quite rarely from its intended purpose.

However, just holding the disc in your palm while weighing it is irrational to sharpen the teeth on the grinding wheel.

No hardness of the hand and excellent eye coverage is enough to make the cutting element perfectly sharp and applicable for effective work.

To keep the circular gear circle in a strictly given position relative to the grinding disc will help, for example, the most ordinary flat stand.

Its surface should coincide with the level of the axis of the grinding wheel. The gear wheel itself is located on the stand in such a way that the sharpened tooth planes are perpendicular to the saw blade.

To grind beveled teeth on the front and rear surfaces, the indicated device is made with a movable hinge.

But in this case, it is difficult to maintain a similar value of the front and rear sharpening angles.

To remove this problem, the center of the saw wheel is fixed in a suitable position in relation to the abrasive disc.

This is done either through the groove for the mandrel, which is mounted on the stand for placement of the sharpened saw on its surface, or by installing special stops on the stand that fix the saw blade at the required angle to the grinding wheel.

Is it worth sharpening table saw blades?

Being able to sharpen your table saw yourself and knowing that you don’t have to rely on spare parts on the go is a real gain in competence and self-confidence for every woodworker.

It was not for nothing that in the past, great importance was attached to the design and quality of a foxtail, for example – it was a carpenter’s companion for many years. How poor are the constructions made of plastic handles and Teflon-coated hardened saw blades.

Conclusion on how to sharpen a table saw blade

Even if it is not used very often, sharpening table saw blades can benefit both your wallet and the environment. The process itself is, as you could see in the article, not difficult at all.

It is important to ensure that the blade teeth are sharpen as evenly as possible so that a clean sawing result is guaranteed later.

As with many other jobs, it is important to be careful and careful when sharpening. Do not use too much force to avoid damage to the table saw blade.

When can I not sharpen the saw blade?

Saws that have a hardened saw blade can generally not be sharpened because the particularly hard teeth cannot be processed.

The wear on these saws from the factory is less, so that the service life is significantly longer than with conventional saw blades.

However, once they are closed, they must be replaced.

Can all table saws be sharpened?

In fact, one has to differentiate between saws with and without specially hardened teeth.

For hand saws with hardened teeth , sharpening is basically

out of the question – unless you have a special sharpening device.

All other saws can be sharpened by hand using a file.

When you should sharpen the table saw blade?

Sharpening is of course particularly useful for saws whose saw blades cannot be replaced.

This includes, for example, the foxtail , the manual counterpart to the electric saber saw.

The blade of the foxtail is particularly thick and wide so that it can be used to make heavy cuts.

For this reason, most models only have a rigid, non-replaceable saw blade.

The fine saw, on the other hand, is used for fine cuts.

This has a thin saw blade with very small teeth so sharpening makes sense.