13 Essential Tools For Woodworking – A Detailed Guide

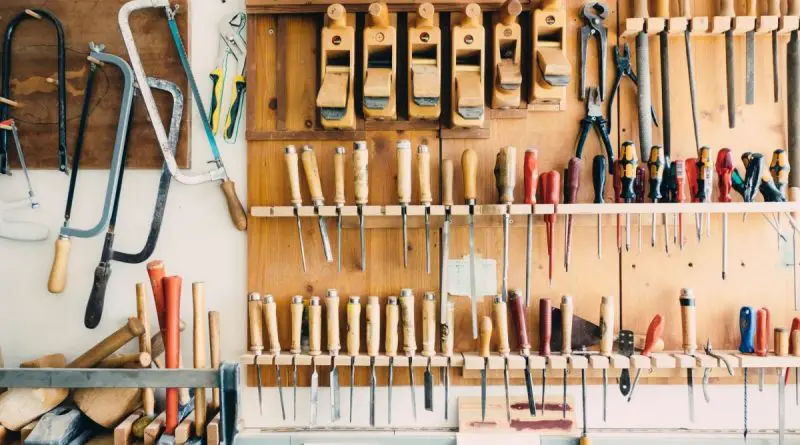

Don’t know which tools to use for woodworking? Once уоu start, уоu will nееd a variety оf woodworking tools but don’t have tо spend a fortune. These tools for woodworking are classified according to the way of wood processing.

In the field of woodworking or wood carpentry, a great variety of woodworking tools and machines are used. We find tools for woodwork processing, tools and accessories for them. Most of the machines and tools used in woodworking, carry out different operations of wood processing through cutting, grinding, carving.

A quality tool or woodworking machine has an appropriate price and guarantee, different from a lower quality woodworking machine.

In small workshops we will meet the ones operated manually and when we work at a larger volume or need very high precision when cutting we will use those controlled by the computer.

A professional usually has a well-developed collection of quality tools for woodworking, with the proper tool for each job.

The range of tools for woodworking and equipment available is best highlighted in terms of material path from its beginnings as a tree trunk to the final product.

In this article, we present a list of some basic woodworking tools, in order to help you open your own woodworking workshop, either professionally or as a hobby.

Woodworking tools and their main characteristics

Some of the most important woodworking tools are presented in detail below:

#1. SAWS

Miter Saw

The miter saw is a type of circular (circular) saws, the main purpose of this specialized power tool is precise cross-cutting of workpieces.

Thanks to the use of a miter saw with a broach, the cut is obtained evenly at the desired angle.

Thus, miter saws are designed for angular and oblique cutting of workpieces from a variety of raw materials (wood, plastic, iron, etc.) under all kinds of inclinations.

Miter saws are used to process various materials. From wood to soft non-ferrous metals such as aluminum and its alloys. For cutting plastics and other plastics. For each type of work, special saw blades are used. They differ in type, size of the tooth, material of the cutting edge, angle of sharpening (attack).

Jigsaw

The jigsaw in your home will be one of the most essential cutting and sawing tools. It is indispensable not only for a professional furniture maker, but also for household chores and crafts.

Here it should be said about battery models of tools. So cordless jigsaws are considered simply irreplaceable in the absence of constant power lines, especially with Li-Ion batteries, and the rubber handle allows for safe operation and low noise level.

The jigsaw is mainly used to make curved cuts in plywood, chipboard, fiberboard and similar materials.

This tool is suitable for shaping miniature workpieces, and due to the possibility of curving linear passage of the web over the material, it is convenient for them to round corners on the workpiece.

Chainsaw

A chainsaw is a special tool used for cutting and further processing wood. In most cases, a chainsaw is a versatile chain saw that has a two-stroke engine.

The chainsaw headset includes: a chain, which consists of links of various shapes and sizes, closed in a ring; bus (metal plate to which the chain is fixed); chain wheel. The fuel is a special mixture designed for two-stroke engines made of gasoline and oil.

The chainsaw is primarily intended for sawing wood: prepare firewood, cut down a fallen tree, cut off thick tree branches. It is no coincidence that chainsaws, especially light ones, are in great demand.

It is worth choosing a chainsaw based on the tasks that it plans to perform. All models of chainsaws can be divided into professional, semi-professional and household.

Professional chainsaws are much more powerful devices that can be used twelve to sixteen hours a day.

They can be used to cut and saw large trees. Such models are necessarily equipped with ergonomic handles, their body is balanced and has increased vibration protection. The natural high cost is due to their high performance. For construction professionals, just such a tool is suitable.

Semi-professional, as their name suggests, is an intermediate option. They can perform all the same work as professional ones, only for a limited time.

Circular Saw

The types of circular saw for wood can be classified according to numerous criteria.

Depending on the technological operation they perform, they can be:

- Circular saw for cutting logs – this model is used for cutting logs and obtaining timber pieces;

- Circular saw (or circular saw) – this model is used for cutting and carving timber pieces;

- Formatted circular saw – this model is used for the processing of semi-finished panels (PAL, PFL, MDF, OSB, etc.) to give them the final dimensions;

The models of circular saw with manual advance are used mainly in the small woodworking shops, as well as in the companies with activity of wood processing being the basic equipment in the factories of small production volume or with the production of unique pieces and small series.

The models of saw with automatic advance (mechanical advance) realize the advance of the work piece by means of mechanisms with rollers, tracks, chains etc. and are ideal for factories with mass production activity with high productivity

Timber factories

Stationary woodworking machines, such as chainsaws and circular saws, are often used in sawmills for cutting logs in easy-to-handle dimensions. The circular saws used are often of considerable size.

Band saw

Band saw is the ideal tool for splitting wood in sections. Instead of a rotary disc, the band saw uses a live circular saw band which makes it less durable than circular saws. However, saw bands are very cheap.

Handsaw

A handsaw is used for sawing wood workpieces. Its design is very simple,a blade with sharp teeth and a handle.

Cutting is carried out with a reciprocating motion provided by the user. A handsaw is used in small-scale repair and construction works, as well as in home workshops.

Handsaws are used not only for sawing wood materials, but also for other, more durable ones, for example, metal and concrete.

Of course, tools vary in design and size based on what you have to cut. The correct choice greatly influences not only the quality of the cut, but also the productivity, as well as the durability of the tool.

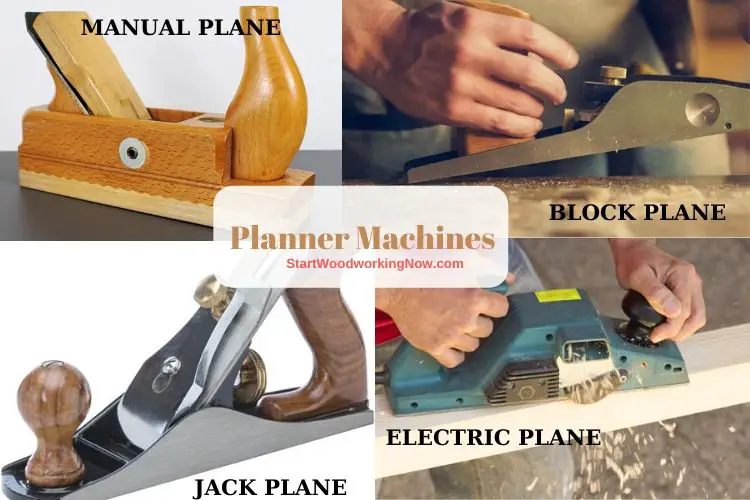

#2. Wood Planning Machines

Bringing a piece of solid material to the right length requires special woodworking tools, such as a large-scale wood plane machine:

- Hand planes are made from steel or wood and are used for a variety of purposes.

- A jack plane is used for rough shaping and comes in twelve to fifteen inch sizes.

- A block plane is used for trimming. Smoothing planes are good for fine cuts and are eight or nine inches long.

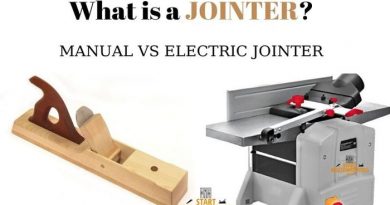

Manual Planers

Manual planers are very old tools in the field of woodworking. The classic model is the hand planer that is still used by many carpenters. The device gives the wood a smooth surface.

Manual planers are cheaper and come in different styles and sizes. You’ll also find that it gives you more control when performing a task, making it ideal for smaller, more detailed projects.

When you decide to buy a manual planer, you should look for one that has good quality, strength, and most importantly, comfort.

Since you will be the one providing the power for the manual planer, it is best to purchase one that matches your comfort level so you don’t get bored very quickly when using it. So be sure to test out the different styles if you can before making your choice.

Jack Plane

The name Jack Plane comes from the saying “jack of all trades”, which implies that it can be used for dressing timber down to the correct size, smoothing and edge jointing especially on smaller pieces of work..

The Jack Plane is the first plane used on rough surfaces and can take over from the scrub plane, shaving small amounts of wood.

A jack plane is a general-purpose bench plane often used by woodworkers as a planer for fitting components. This tool is used for the machining of wood.

Electric planers

Today, there are also electric powered planers that accompany the traditional version.

Electric planers are more powerful tools and are suitable for both large and small woodworking projects. Since you don’t get the kind of control you would get with a manual planer, you should practice using an electric planer when working on smaller, more detailed jobs.

The electric planer is used to obtain a flat face of the work-piece, as well as to straighten the edges of the work-piece (using the parallel adjustable angle), and the grinding machine, the thickness planing machine, is used to obtain the other face. of the work-piece perfectly flat and parallel to the first.

When shopping for an electric planer, you can choose between a corded version or a cordless version. If you are on a budget and are concerned about costs, keep in mind that the cordless electric planer can be more expensive in the newspaper run.

Thickness planers are used to reduce large volumes of panels and sleepers to a consistent thickness.

Stationary planers

Stationary planers are ideal woodworking tools for larger and more complex projects. In order to maintain the planer, you should clean it periodically or it will stop working properly.

Stationary planers are large and sit on their own tables. Due to their strength and weight, they can be fed into larger panels than manual and electric planers.

When buying a stationary planer, ask for one that comes with a good quality table extension and depth adjustment, especially if you plan to tackle more difficult projects.

#3. Hammers and Mallets

Carpenter Hammer

It is a piercing tool, for example being used to drive a nail.

The hammer is made of a head and a handle. The head consists of a metal mass, it acts by inertia, increased by the length of the handle and that of the manipulator’s arm. A good hammer is designed so that the grip matches the center of percussion.

Claw Hammer

It is a metal tool used to drive nails or extract points from boards or various woods. (Also called a “nail puller” or “formwork hammer”)

Joiner’s Mallet

It allows you to strike a tool (chisel, chisel, etc.) in order to strengthen the working force, it can also be used for the assembly of certain parts (using a piece of soft wood).

The Rubber Mallet

It has the same use as the wooden mallet but is softer and therefore risks marking the wood less during use, however it can leave black marks that are difficult to remove, so it is better to use it mainly on tools.

#4. Tools for Precision Wood Processing

Milling Machines

The milling machine is also a major tool in woodworking operations. Instead of a saw blade, the milling machines operate using a rotary cutting head whose design determines the milling profile.

A wide selection of tools for wood drills has been designed. The smallest and simplest milling machines are known as vertical milling machines, which are used as woodworking machines by many craftsmen.

Once equipped with a work bench and a mechanical stop system, the vertical milling machines are transformed into bench milling machines.

This is the standard tool for the manufacture of wooden profiles such as window frames or curbs.

CNC Milling Machines

The highest quality milling machines are CNC (computer numerical control) milling machines. They have a milling head that can pass through a block of wood on all sides using three or five axes to create any type of product imaginable

Are used to create complex contours of serial quality and differ from metalworking machines in terms of rigidity.

The wood being a rather soft material means that the machines do not need to withstand the enormous strength of the milling machines for metal.

Instead of a lubricant cooling unit, CNC milling machines rely on a powerful extraction system. Extraction is especially essential for woodworking because complex machines are very sensitive to dust.

However, CNC technology is very important in 2D woodworking and that is why most CNC woodworking machines are in the panel processing sector.

They are used to mill precise and consistent contours in specific panels for a wide range of sizes.

#5. Tools for Assembling

Drill Machine

Drilling is a woodworking tool required for the insertion of bolts, threads, screws and others on wood products.

Drills are available corded or cordless models. Corded drills work well and are less costly .

Great features to look for include reverse, variable speed controls and attachments for a drill press.

If you would like a cordless drill, search for high voltage batteries to make certain it’ll have adequate power.

Search for a model with two batteries, so one will be charging while you work with the other. You may need a range of drill bits for woodworking projects.

Wood drilling, nowadays, is made with specialized woodworking machines called:

- wood drilling machines

- grooving milling machines

- hinged drilling machines

- multiple drilling machines

- wood grinding machines.

Hand drill

Is one of the oldest types of woodworking equipment that has been developed since then in many powerful electric drills and very efficient drilling stations.

Using these, any type of drilling can be performed in a material with precise constant results.

Drilling machines are ideal tools for furniture production and especially for the processing of chipboard.

Cordless drill

The cordless drill is a tool equipped with an electric motor running on a battery , it is used to drill holes in different materials.

Its power is less than a corded drill, but its usefulness (in case of lack of current) and its maneuverability (no wire to drag behind you) make it an essential tool. The removable batteries are recharged on a specific base, comprising an electrical transformer, and a thermal safety cutout.

The cordless drill that runs on a battery is light and handy. Its autonomy and power depend on the voltage and intensity of its battery.

This type of drill is preferred for screwing and unscrewing work such as mounting a piece of furniture, for example, or for drilling and screwing in hard to reach places.

Corded drill

A corded drill is a tool that will allow you to drill all types of materials: wood, furniture, stone, concrete.

The corded drill allows you to carry out a variety of drilling jobs. These drills allow you to work with power both indoors and outdoors, for any drilling, screwing or unscrewing work . This is why we also speak of a screwdriver or screwdriver.

For corded drills, the power is evaluated in watts. The majority of drills have an average power between 600W and 1000W.

This drill is all-purpose! You can replace the bits to work with different materials: tile drill bit, concrete drill bit …

The corded drill may nevertheless have limited use by access to the current. If you are working at the back of the garden, plan a winder so that you are not limited by the short length of wire. Also indoors, an extension will often be necessary.

Ideal for regular and / or versatile DIY enthusiasts, corded drills can be used anywhere and anytime:

- You can drill a wide variety of materials (remember to adapt the bit)!

- You can screw and unscrew quickly, without a screwdriver.

- You can use your drill for other jobs : by adding a milling cutter, a wire brush, a mixer… your drill can turn into a small sander or mixer!

Machines for Inserting Dowels

The range of drilling machines also includes the machines for inserting dowels which are used for inserting dowels and bolts in holes already made.

They make it possible for flat-pack furniture where a number of different parts must be assembled together by the buyer to make the final product.

Without the boring machines, the furniture world as we know it today would be very different.

#6. Wood Turning Tools

Wood lathes

The wood lathe tool is the basis of any woodworking operation. Whatever requires rounding can be worked on this predecessor of the lathe.

The wood lathe is a woodworking tool that allows many people to combine DIY and creativity. Indeed, the wood lathe offers the possibility of working volumes of wood so that they are not only rough, but that they adopt rounded or worked shapes.

The advantage with a wood lathe is that you can quickly have a rendering, a desired shape, but it will be the finishes that will require you a little more know-how and hours of practice.

The principle of the wood lathe is very simple, a motor turns a drive shaft to which the piece of wood to be worked is attached. The wood will occupy an entire space called an between-point until the part is held at the other end by the tailstock.

Using a wood lathe and mastering it requires many hours of trial and error before you can do exactly what you want.

The wood material is fixed and rounded longitudinally. A chisel can then be used to create a contour around the entire circumference of the article.

The simplest lathes for wood are extensions for drilling machines. The lathes for wood today are numerically controlled and can be trusted for the processing of pieces of consistent size.

Chisels

The wood chisel it is a carpenter and cabinetmaker’s tool composed of a hardened steel blade, called a plank, one end of which is bevelled and extremely sharp to allow woodworking.

The other end, called tang, is stuck in the axis of a handle, in wood or in synthetic material, for a better grip.

The chisel is a fragile tool, the end of the handle is only struck with the palm of the hand or a mallet to facilitate penetration.

You’ll need a range of chisels in sizes from ¼ to 2 inches wide, depending on the project. Chisels are often used by hand or you can tap them with a wood mallet.

Mortise Chisels

It is a tool close to a wood chisel, but thicker, which gives it more resistance. The mortise chisel is used to make the mortises allowing to accommodate the tenon, the base of the assembly of the furniture.

The mortise chisel is also used as a cutting tool for the realization of wooden parts turned between points. Like the chisel, it exists in different widths.

Router

One of the most important electrical tools for home woodworking is the hand router. They grind the edge, making it rounded, curly, cut out grooves, drill holes.

They produce various types of milling cutters with a wide and narrow spectrum of action.

They differ in power, cutter shank diameter, maximum rotation speed. In addition to wood, drywall, plastic, and acrylic are processed with a router.

#7. Wood Finishing Tools

Sandblasting and grinding machines are the tools responsible for carrying out the final processes in wood processing.

They remove the slightest imperfections and create a smooth and smooth base for subsequent machining.

The machines used are grinding machines with tape and disk that can take the form of hand tools to industrial machines for large series production.

Belt sander

The belt sander, also known as roller sander, is a power-portable machine specially designed for sanding. It walks back and forth, and it is equipped with 2 parallel rollers on which is attached a strip of sandpaper.

Is very heavy and offers good power, it is perfect in the case of beams and joists.

The belt sander is an essential tool for any handyman who wants to have professional renderings. It helps to carry out complex and large-scale work.

In the house, it is very useful for carrying out renovations and for making crafts. It allows you to renovate a room and repaint it, give the parquet a facelift, polish old furniture before varnishing them, cut the tiles

Orbital sander

The orbital sander is a portable manual tool that is used to sand different materials such as glass, metal or wood. It consists of an electrically powered turntable, which is equipped with a disc. The latter may have different diameters.

Is light, you use it to sand curved shapes and it is also very efficient in finishing.

The orbital sander is a hand-held power sander primarily used for coarse to fairly fine sanding of surfaces to be sanded.

The orbital sander allows you to perform finishing and semi-finishing work. It is not only effective on wood or glass.

Depending on the abrasive used, this accessory can act on several types of metals , on PVC and synthetic materials, aluminum and even ivory.

Eccentric sander

The eccentric (or roto-orbital) sander does not stand out for its extravagance, but rather for its versatility!

Thanks to its plate which is not connected to the motor shaft but is eccentric on an intermediate plate, you can perform a wide variety of jobs. It can help you with coarse sanding as well as finishing work , even polishing and polishing.

Is recommended for finishes and flat surfaces. Having an ergonomics comparable to the orbital sander, it is easy to handle.

Giraffe sander

Like a giraffe with its long neck, a giraffe sander is suitable for vertical surfaces ! These sanders are perfect for sanding plasterboard strips or joints.

The giraffe or wall sander is reserved for sanding high surfaces.

The parquet sander

Is ideal for the latter, although other sanders can be used, it offers better performance.

Wood grinding machine

Is an electrical equipment used for grinding wood surfaces with the help of abrasives: abrasive tape, abrasive disc, abrasive stone, etc.

A wood grinding machine can be provided with many ways to fix the abrasive and its quick change, as well as a support or the possibility to be fixed on a work bench.

A wood grinding machine is usually powered by an electric motor and sometimes works with a compressed air system.

Models of planing and grinding machines also known as abrasive machines, grinding machines, machines coated with thickness, are woodworking machines used to straighten the faces of wooden parts.

#8. Files and Rasps

There are different shapes and sizes .

The difference between file and rasp is that the former is used for more delicate sanding and has a thinner teeth, while the file is used for roughing and more massive operations .

In fact, the rasp has a thicker and more powerful texture. However, both are very useful.

Flat File

It is a tool for machining material. It works by tearing off small pieces of the material, the work is generally carried out in multiple passes of the rasp on the workpiece. There are multiple shapes (flat, round, square) allowing to adapt to the shape to be obtained.

Flat Pointer File

Like the armchair rasp, this hand-stitched rasp is ideal for cabinetmaking work, but its profile allows for more hollow shapes.

Triangular File

It has the same application as the mid-round, but to carry out finer, more precise work. Rasp very popular with modelers, moulders. Available in lengths of 150 to 300 mm, stitches ranging from n ° 3 to n ° 15.

Straight or Curved Iron Rasps

Rectangular in profile, with 3 useful faces, these rasps with angled tang, are very popular for restoration work on furniture or for finishing bas-reliefs. Available in widths from 10 to 30 mm

Needle rasps

Indispensable for very meticulous work such as violin making, model making, model making or for all very small parts. Available in four forms:

- Half round

- Plate

- Rat tail

- Knife

Available in length of 180 mm.

#9. Tools and Instruments for Measurements

The following tools and instruments for measurements should definitely be a part of any woodworking workshop:

Folding Meter Stick

The folding rule is a measuring instrument used in the field of construction, woodworking and DIY in general .

Is made of wood or metal with a length of 1 m or 2 m. The wooden meter is made of hornbeam, beech blades, articulated with ‘rivets’.

It is made up of several 20 cm branches (5 for 1 meter, 10 for 2 meters) attached to each other by rivets equipped with a spring allowing the meter to be fixed in the closed or open position.

This folding rule is made of aluminum, but it can also be made of wood or plastic.

Both sides of the meter are graded from left to right, indicating mm and cm.

Pocket Tape

Is used when determining the dimensions to which the wood must be processed. It is made of an elastic steel blade, slightly curved in width to have rigidity, in progress. It has lengths of 1m, 2m, 3m.

Measuring Tape

It has the same functions as the folding rule but has the advantages of taking up less space and taking much larger measurements, it generally measures between 2 and 5 meters.

The caliper

Is a tool that measures the diameter of wooden objects as well as those of metal. They can also measure depth. The measurement accuracy is tenths of a millimetre

The caliper is a measuring instrument intended for the determination and control of small distances. This instrument is very precise, it allows to easily measure the external dimensions of a part or the diameter of a hole.

The protractor

Used for measuring or tracing angles. The use of the protractor is sometimes replaced by the use of a half-square .

The trigonometric protractor is a measuring instrument materializing the trigonometric circle and providing a degree-radian correspondence.

In woodworking and industry, metal protractors made up of a circular sector associated with a pivoting rule and a locking device are more readily used.

Micrometer screw gauge

Is used to measure the thickness of the parts.

Squares

Are important for accurate measuring. You’ll need a framing square or a carpenter square.

A try square

Usually utilized in furniture making. These come in sizes from three to 12 inches. search for squares that are marked in inches and metric. a mixture square has two pieces: a head on a steel blade. These are an excellent tool for measuring 45 or 90 degree angles.

The spirit level

It is a measuring instrument designed to indicate whether a surface matches the reference angle. for example

The spirit level is a very precise measuring instrument and very useful for carrying out many DIY jobs. It is this which will make it possible not to hang a crooked frame on the wall, not to mount shelves at an angle, to build a straight garden wall for example.

The purpose of the spirit level is to check that an element is plumb, horizontally or vertically. Every good handyman should have a spirit level in their tool kit .

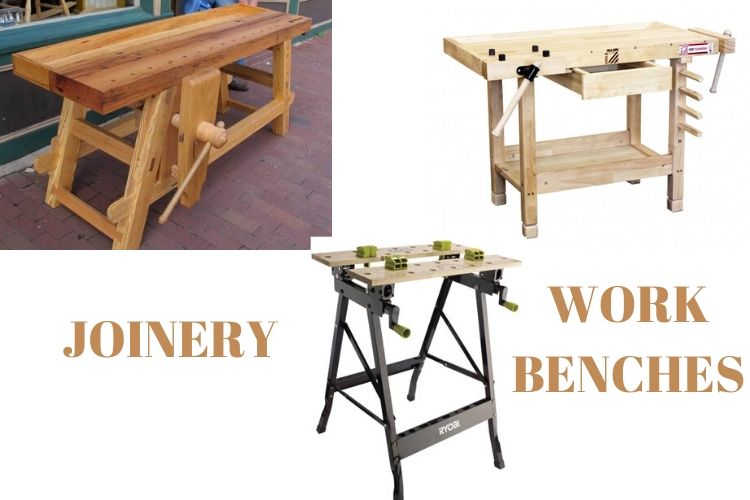

#10. Joinery Bench

A joinery bench is a work bench used by woodworkers to fix the work pieces.

There are many types of joinery benches, each reflecting the type of applications to be made by the carpenter and his way of working.

Most models of woodworking benches have two common characteristics, namely:

- they are sufficiently rigid to support the piece of wood to be processed and are equipped with systems for fixing the work piece so that the working position

- height are comfortable for carpentry so he can use both hands for processing.

The main criterion of differentiation between models of carpentry benches is the type of fixing of the piece.

From this point of view, a woodworking bench can be provided with:

- Limiter fastening system – this system is composed of a piece of wood or metal salt just above the work piece at its end.

- Quick fixing system – in this case the fixing is done with the help of hooks that press on the top of the carpentry bench at the top of the work piece.

- Hole fixing system – it is a common fact that the top counter top is provided with holes through which bolts can be inserted to fix the work piece.

Clamps

Another woodworking tool used is clamp. They are needed for gluing projects together.

Clamp is essential for assembling or gluing different wooden planks for example. There are different models such as the press clamp, the dead clamp, the clamps, the screw clamp

Clamps allow you to fix one or two assembled pieces in place on your workbench. In this way, you can weld, drill, cut or dry the part easily.

They differ by their opening which ranges from a few centimeters to several meters, by their clamping power and by their depth. The tightening is maintained by screwing in the frame of screw clamps, C, pump or fixed, by pinching for spring clamps, ratchet, pliers.

A large variety of sizes are available. These are generally inexpensive, so pick them up whenever you find them.

These can often be found utilized in good condition. Pick them up whenever you find them cheap to make your collection.

#11. Nail Guns

The pneumatic nailer: very practical

This type of nailer works from a cable connected to a compressed air device. This tool projects the nail into its magazine with the force of compressed air to fix the nail.

The gas nailer: works with combustible gas

It works with a combustible gas. The gas is brought to a certain temperature then explodes, this explosion pushes the piston which then propels the nail. To control this detonation, an electric battery is supplied with the nailer.

Electric nailer

If you don’t have an air compressor in your home, and you don’t want to buy a pneumatic model, the electric nailer may do the trick. Although it is generally less powerful than a pneumatic nailer, you will be able to use this tool for most cabinet work or on fabric.

The powder nailer: same function as a firearm

She and the split nailer are two types of materials that work with powders. You should know that the first uses gunpowder to work. Their operations are more or less reminiscent of the operation of a firearm.

#12. Sawdust Extractors

Worst of all, breathing saw dust can have a significant effect on your health. Most cities now have requirements that each one commercial woodworking shops have dust gathering and removal systems.

An over-arm blade cover with dust collection for your table saw are often just what you would like to control dust.

Coupled to an appropriate dust collection system the blade cover will collect the dust because it flies off the revolving saw blade, keeping your shop and therefore the air you breathe clean.

Secondary processing of wood in carpentry workshops generates a large amount of dust and sawdust.

To remove dust and sawdust from the workshops, sawdust extractors or vacuum cleaners for dust and sawdust are used successfully.

For some hand tools the use of a sawdust vacuum cleaner can be a suitable solution for dust and sawdust aspiration.

In contrast, for large-scale woodworking machines such as circulars, coat machines or wood thicknesses, milling cutters, etc, it will be necessary to use an exhaust system with a larger diameter and flow connection hood.

Sawdust collector for small workshops

For small workshops (for amateurs), a small dust collector with filter bag, usually a mobile dust collector, is an excellent choice for minor woodworking operations due to the low purchase price and suction capacity (usually up to 1000 m3 / hour).

Sawdust collector for medium size workshops

If the workshop is medium in size or equipped with woodworking machines that require a higher suction rate, then the use of sawdust vacuum cleaners with engine power between 1.5 – 3 hp is recommended.

Sawdust collector fans in this category usually have a capacity greater than 2200 m3 / hour and develop a static pressure of 10+ inches.

The cleanliness in the wood processing workshops is ensured by the use of dust and sawdust vacuum cleaners, also known as sawdust collectors.

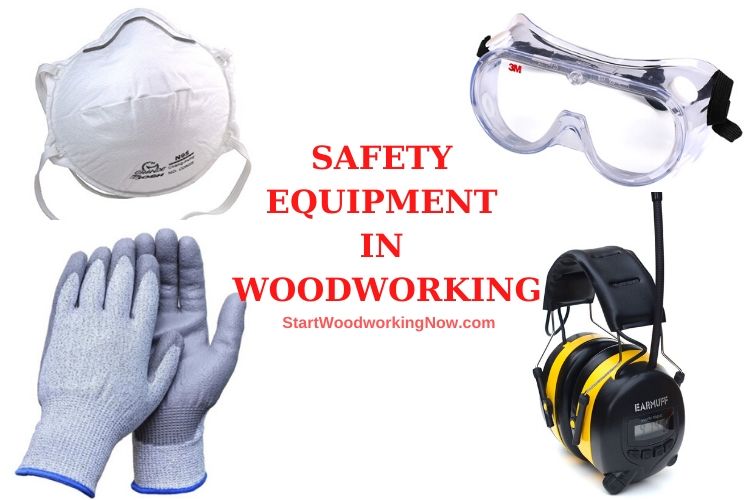

#13. Safety Equipment in Woodworking

With electric machines equipped with high cutting or drilling capacity, unwanted accidents can easily happen if you do not take all precautionary measures.

Thus, before using a woodworking tool for the first time, carefully read the manual provided by the manufacturer and strictly follow the instructions provided.

In addition to these you also need protective equipment, namely:

Safety Goggles

Safety glasses are the most important safety equipment. There are many types of goggles, but they all share the same characteristics, namely, impact-resistant lenses and side shields to protect against dust and dirt generated by power tools.

Ear Protection

When working with noisy power tools and machines such as cutters, planers, and carpenters, it is advisable to wear hearing protection. There are two common types: expandable earbuds and earmuffs.

Earmuffs tend to offer slightly better protection, but they can be very cumbersome and cumbersome.

Consistent use of hearing protection protects you from long-term hearing loss.

Respirators and Face Masks

Grinders, milling cutters, and other power tools can generate a lot of dust. When using these tools, you should wear a dust mask to keep these fine particles from getting into your lungs.

When spraying varnish or paint, a respirator is a better choice to protect you from the harmful effects of using these chemicals.

Face Protection

If you use a lathe you will likely create a lot of fly chips. Aside from using your safety glasses, clear full face protection is a good idea.

The shield is comfortable, can be flipped up when not in use, and will keep most of the flying debris away from your face.

Appropriate Clothing

When working with power tools, you should always wear appropriate clothing. Therefore, you should never wear loose-fitting clothing.

Comfortable, long-sleeved shirts and long trousers in combination with good work shoes with steel toecaps each provide a protective layer.

However, loose clothing can easily get caught in a very dangerous power tool. Sometimes a shop apron is also a good idea, especially when using a lathe.

Protective gloves

The hands are also very exposed to the risk so do not forget to use protective gloves.

Adjacent to the category of woodworking machines, sharp woodworking tools are used. They are divided into:

- sharpening machines for knife sharpeners

- sharpening machines for circular saws (sharpening machines for circular saws)

- universal sharpening machines.

Striking tools:

- Clippings;

- Claw hammer;

- Locksmith hammer;

Othеr woodworking tools уоu will nееd include:

Jet Power Tools For All Your Woodworking Projects

Setting up shop is simple once you have a supplier which will provide you with Jet power tools. The top-of-the-line woodworking and metalworking tools are often found at over 9,000 dealers world-wide.

All About Jet Power Tools

Jet power tools aren’t just made in one place, but are a set of the best technology and materials from round the world.

The tools are manufactured in areas where engineers have perfected specific crafts and designed the tools to support them.

One of the unique qualities about Jet power tools is that they need the accessories that are most useful to every tool.

For instance , power saws are supported by products like the Cyclone Dust Collector and Parallel Clamps. This makes working with the saw more efficient and creates a far better workshop environment.

Jet power tools are backed by warranties on each and each product. Authorized Jet distributors stand behind this warranty also .

All tools are often maintained and services at authorized Jet service centers round the world. If you ever need a part, it’ll be available once you need it.

Replacement and spare parts are well inventoried with over $3 million of parts available at any given time.

And the Winner Is…

Jet has been the recipient of the many prestigious awards within the power tool industry. Woodworking magazines are consistently rating Jet tools because the finest brand of power tools on the market.

The awards don’t come easily either. they’re supported a comparison of all tools within any given category from round the world and in the least price levels.

What you’ll Get From Jet Power Tools

In addition to quality you’ll get one among the widest types of power tools from Jet. The Jet lathe, Jet table saw and Long Bed Jointer are among the convenient woodworking tools by Jet.

One special item from Jet is the portable horizontal band saw. This lightweight series of saws are great for jobs outside of the workshop. They’re small, yet big on capabilities.

The blades are often adjusted to 45 and 60 degree angles great for miter cuts. The bi-metal blade makes it durable and ready to handle jobs that normally require much bigger saws.

There’s also an optional floor stand that instantly turns the band saw into a multi-functional table saw.

To get the most from these portable saws and every one of the tools carrying the Jet name, Jet has created training videos.

These videos feature all of the highest products by Jet in their training series referred to as the “Shopclass Series.”

Either WMH Tool Group or specific distributors can provide you with the list of titles to assist you complete any job.

Jet power tools are one brand supported by parent company WMH Tool Group. This long-standing leader in tools also provides the Powermatic and Wilton lines to serious craftsman and do-it-yourself homeowners alike.

To get an proper search close at the entire line of Jet power tools you’ll visit a distributor or attend one of the various industry trade shows where WMH Tool Group sets up their interactive booth.

Finding Woodworking Tools

Don’t rush out to shop for the most affordable tools you can find to supply your workshop. Wait until you’ll afford quality items which will last.

Buying cheap tools for woodworking may be a decision you may well live to regret. A decent set will last for years, unlike cheap tools which will need to get replaced repeatedly over the same period of time .

The internet may be a good place to look for discount woodworking tools. Search for renowned names, like Rockwell tools, Sears tools, Hitachi tools and Ridgid tools.

Rockler woodworking tools are renowned for quality. By purchasing major brands that are known for quality, you’re more likely to finish up with a product which will offer you years of dependable use.

One way to find quality tools for woodworking at a reasonable price is to buy them used. These are often found at flea markets, yard sales, antique auctions or your local classifieds.

Tools are often in good condition, particularly if they got little use. Hand tools are nearly always a good bet when purchased used.

Be careful when purchasing used power tools. they’re generally good if they were gently or rarely used.

Check them out thoroughly and take a look at them to make sure they’re in good condition. Ask about how often they were used and once they were first purchased to get a far better idea of the overall condition.

Advantages of Using the Proper Tools for Woodworking

By using woodworking machinery in the woodworking avoids the high level of noise and vibration felt during manual operation. Also the finishes are better, resulting in a higher quality of the final product.

The woodworker can use these machines and make pieces with an artistic sense, significantly reducing the working time.

They are often found in workshops that model, cut, sculpt, shape, drill wood material.

For all these different operations, specific machines are used. They should be chosen as best for the correct needs and level of technical knowledge of the users:

- Thus we will use a saw (circular or with table) when it must be cut with great fineness or at a very sharp angle, they can be inclined allowing adaptability in various and very useful machining providing accuracy when processing larger lengths.

- It is basic in any location where woodworking machines are used, especially of larger dimensions and can be cut angular, straight or round

- For finishing and finer we recommend a milling machine with which we will obtain more precise results. The workplace is fixed with a sleeve that allows the user to exact cutting it.

- A wood drilling machine will be used for several functions, not just for the main drilling machine. These holes can also be given in a different angle, allowing flexibility in the operation of the piece.

- Mechanical sawmill cuts the wood to various dimensions, making in this way all kinds of products from toys to decorative pieces, artistic elements of sculpture.

- When the space is not very permissive in the workshop, you can use a band saw, which is very compact and manageable.

CONCLUSION

Most tools for woodworking is divided into three basic categories:

- hobby type tools – for occasional low power work;

- semi-professional tools – for small workshops that have small wood processing works;

- professional tools – for those who only deal with such works and need high performance equipment and high power.

The range of machines and tools for woodworking, we presented to you is addressed both to domestic users and to the big producers in the wood processing industry.

The difference will be felt at the price and carefully choose the model to adjust to your needs, without investing too much if not necessary, but also a low power equipment used to the maximum will need frequent repairs.

Most woodworking machinery increases productivity, decreases eventual losses, allows precise cutting and quick shaping of wood.

These machines and tools will help us in the job and will shorten the working time, allowing to obtain quality works in any woodworking field: furniture manufacturing, toys making, timber processing.

Woodworking can also be done intuitively, with love and passion, with the right tools that will ease your work and help you achieve high results.