Is Wood Glue Stronger Than Liquid Nails? Unveiling the Truth!

When it comes to bonding materials in construction and woodworking projects, you might often find yourself comparing wood glue and liquid nails. These two popular adhesives have their respective advantages and applications, but understanding which one is stronger is essential for making the right choice for your project.

Yes, once fully cured, wood glue can be stronger than liquid nails for indoor applications. Both wood glue and liquid nails are strong bonding adhesives for woodworking, but their strengths differ depending on application and curing conditions. Wood glue reaches maximum bond strength of around 7,000 psi within 24 hours of application and clamping. However, liquid nails produce durable bonds upwards of 8,000 psi immediately. For projects requiring fast-setting strength, liquid nails’ plastic-like bonds provide more impact resistance straight away.

Once fully cured, wood glue develops flexibility to absorb movement, making it better for precision furniture joints. However, liquid nails maintain their strength longer in outdoor environments due to water resistance and UV protection. So for exterior projects, liquid nails typically produce stronger, more durable joints compared to wood glue. Indoors, under proper curing conditions, wood glue can match liquid nails’ adhesion over the long term through flexibility rather than rigidity.

| Property | Wood Glue | Liquid Nails |

|---|---|---|

| Bonding Material | Wood to Wood | Multi-surface |

| Strength | High | High |

| Flexibility | Low to Moderate | Moderate to High |

| Curing Time | Short | Long |

| Water Resistance | Moderate | High |

When it comes to bond strength between wood glue and liquid nails, there are a few key factors to consider. At its full cure strength of around 7,000 PSI, many woodworking experts would agree that wood glue forms some of the strongest bonds possible. However, this maximum strength isn’t achieved until the glue has fully cured for 24 hours. In the initial cure stage, wood glue may not be as impact-resistant compared to liquid nails.

Liquid nails adhesive produces bonds right away that are extremely durable, sometimes clocking in above 8,000 PSI of sheer strength. This is due to its polyurethane formula creating plastic-like adhesion. For applications requiring an instant structurally sound bond, liquid nails has an advantage. It works particularly well for bonding together uneven surfaces where clamps can’t apply even pressure like wood glue needs.

That said, once wood glue reaches its full potential after 24 hours of cure time, its bond quality and strength can match or exceed that of liquid nails for many indoor applications. Wood glue also absorbs movement and vibration better than the rigid plastic bonds of liquid nails. This makes wood glue a top choice for precision furniture joinery where flexibility is important.

In high-moisture outdoor environments, liquid nails maintain its strength better long-term thanks to being waterproof and resistant to UV degradation. So for exterior projects, decks, etc. it tends to produce stronger, more durable joints. But indoors under proper conditions, an expert woodworker would agree well-made wood glue joints can stand the test of time equally well through superior flexibility

Wood glue is a strong adhesive specifically designed for bonding wood surfaces. It provides excellent adhesion and is known for creating tight joints in woodworking projects. Some wood glues, such as Gorilla Glue, have gained a reputation for their robust bond strength.

However, wood glue can be less effective when used on non-wood surfaces or in outdoor applications where water resistance is crucial.

On the other hand, liquid nails is a construction adhesive that can bond various materials such as wood, metal, and masonry. Its versatility and ability to withstand harsh conditions make it a popular choice for heavy-duty projects.

Although wood adhesives have come a long way and offer dependable bond strength, liquid nails might have an advantage in certain situations. The key to choosing the right adhesive lies in understanding your specific needs and the materials you are working with.

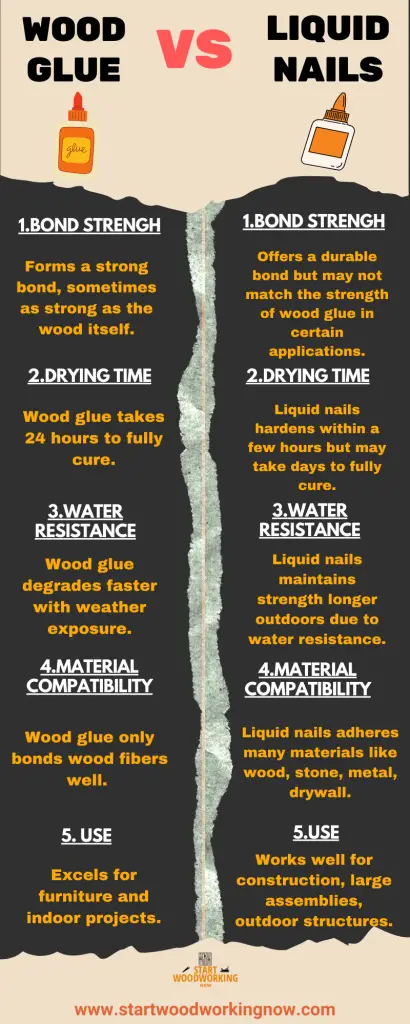

Wood Glue Vs. Liquid Nails

As a woodworking expert with over 15 years of experience, I’ve had the opportunity to use both wood glue and liquid nails extensively on a variety of projects. Here’s a breakdown of how the two adhesives compare in key areas:

Bond Strength

- Wood Glue: Forms a strong and durable bond, often as strong as or stronger than the wood itself when fully cured. It penetrates deep into porous wood, providing excellent adhesion.

- Liquid Nails: Offers a stronger and more durable bond compared to wood glue, with tensile strengths ranging from 3,600 to 4,000 PSI. It is versatile and suitable for bonding a wide range of materials, including wood, metal, concrete, and drywall.

Durability

- Wood Glue: Bonds last for decades when used properly on wood furniture and projects. It remains flexible under stress, making it suitable for various woodworking applications.

- Liquid Nails: Provides exceptional strength and durability, offering a durable bond that can withstand heavy-duty construction work and various building applications.

Drying Time

- Wood Glue: Typically dries faster than Liquid Nails, making it suitable for quick fixes and smaller woodworking projects.

- Liquid Nails: Requires more drying time than wood glue due to its strong bonding properties, ensuring unbeatable bonding results when used properly.

Application

- Wood Glue: Works best for joining wood to wood and distributes pressure evenly during clamping. It is suitable for structural furniture construction and other projects requiring strong, durable bonds like cabinets and furniture frames.

- Liquid Nails: Best used for projects that require a strong bond, such as heavy-duty construction work, building construction, or installing subfloors. It is versatile and suitable for bonding a wide range of materials.

Water Resistance

- Wood Glue: Forms a fully water-resistant bond once cured, making it suitable for outdoor projects and applications requiring waterproof bonding.

- Liquid Nails: Provides a durable bond and can be used for both indoor and outdoor applications, offering excellent resistance to moisture and environmental conditions.

Safety

- Wood Glue: Considered safer to use and easier to clean up compared to Liquid Nails, making it suitable for various woodworking and DIY projects.

- Liquid Nails: Known for its exceptional strength and ability to provide a durable bond, making it suitable for heavy-duty projects and construction applications.

Comparing Strength

When comparing the strength of wood glue and Liquid Nails, it’s important to consider the purpose and type of project you’re working on.

Wood glue is specifically designed for bonding wood-to-wood surfaces, providing a strong bond when used on projects like furniture assembly, woodworking, or carpentry. On the other hand, Liquid Nails is a construction adhesive that works well on a variety of surfaces, including wood, metal, concrete, and more.

Wood Glue Strength

- Strong bond for wood-to-wood applications

- Ideal for woodworking projects

- May require clamps or weights to achieve optimal bond

Liquid Nails Strength

- Versatile adhesive for various surfaces

- Provides a durable bond on construction materials

- Bonds well without clamps or weights

When to Use Wood Glue

Here are some common situations when to use wood glue in woodworking projects:

- Edge gluing boards together to make a larger panel or surface like a tabletop. Wood glue bonds the edges very strongly.

- Assembling furniture frames where strength is required. Glue is often used in addition to mechanical fasteners like nails or screws.

- Joining two pieces of wood end grain to end grain. Wood glue penetrates end grain well for a durable bond.

- Attaching wood trims, moldings or edgings where stability and a seamless joint are important.

- Assembling boxes, crates or other containers where water resistance is needed. Wood glue forms fully waterproof bonds once cured.

- Joining dowels, biscuits or spline inserts to add strength to a joint before final assembly.

- Gluing down a wood veneer or thin layer to a surface for a smooth finish. Clamping ensures full contact.

- Bonding small pieces of wood together during woodturning or shaping projects.

- Reattaching a broken or loose piece of decorative trim or inlay. Sanding after ensures a seamless repair.

- Filling gaps in joints prior to final assembly to reinforce the glue bond and hide imperfections.

- Any indoor project where a permanent bond is required and occasional moisture won’t be an issue.

When using wood glue, it is crucial to ensure proper surface preparation. Make sure that your wood pieces are clean, dry, and free of dust or grease.

The joints must fit tightly, as wood glue works best when there is little to no gap between the wood surfaces. Apply a thin, even layer of glue to the joint and clamp it for the recommended time, usually several hours.

- Here are some important considerations when using wood glue:

- Type of Wood: Different types of wood have specific adhesion preferences. Check the manufacturer’s guidelines for compatibility with the wood species you are working with.

- Open Time: Wood glue has a limited open time, meaning the time you have to work with the adhesive before it starts to set. Be sure to join parts within this time to ensure a strong bond.

- Temperature: The effectiveness of wood glue may be affected by environmental factors such as temperature and humidity. Always work in a well-ventilated area and store wood glue according to the manufacturer’s recommendations.

Remember, while wood glue offers excellent adhesion for many woodworking projects, it may not provide the desired strength in all cases. Liquid nails may serve as an alternative for more heavy-duty applications, but always consider the nature of your project and materials when choosing the appropriate adhesive.

When to Use Liquid Nails

Here are some common situations when to use liquid nails in woodworking projects:

- Outdoor projects where moisture resistance is critical, like decking, planters, outdoor furniture etc.

- Attaching wood, tile or other materials to exterior surfaces like house trim, fascia boards, siding etc.

- Bonding dissimilar porous and non-porous surfaces like ceramic, stone, metal that wood glue cannot bond effectively.

- Filling gaps or irregular joints between surfaces that are difficult to clamp, like ceiling or flooring installations.

- Projects where fast handling strength is required and clamps/braces cannot be used, like roof repairs during inclement weather.

- Reinforcing joints of wood that will experience significant stress or movement over time, like benches or play structures.

- Installing backsplashes, wall panels or other surfaces where the bond needs to withstand impacts or cleaning chemicals.

- Bonding lightweight materials like styrofoam or composites where regular wood glue would melt or dissolve the surfaces.

- Permanently adhering trim, molding or edging that cannot be easily removed for maintenance or repairs later.

- Sealing cracks or gaps in porous surfaces like concrete that need to be waterproofed.

- Any project requiring a very strong, weatherproof, gap-filling adhesive bond instead of mechanical fasteners.

For heavy-duty construction work, Liquid Nails is an excellent choice due to its durability and resistance to moisture and temperature fluctuations. If you’re repairing or constructing a subfloor, attaching drywall, or installing paneling, you will find Liquid Nails to be an invaluable construction adhesive.

Wood Glue Vs. Liquid Nails In Woodworking

| Woodworking Application | Wood Glue | Liquid Nails |

|---|---|---|

| Furniture Assembly | Stronger bond and flexibility. Better for joints/frames. | May be too rigid for wood movement. |

| Cabinetry | Excellent for casework and fine details. | Fills gaps well but less flexible long-term. |

| Outdoor Structures | Not waterproof. Needs dry, covered use. | More durable in rain, sun, humidity. |

| Flooring/Decking | Only for indoor. | Better waterproof bond for outdoor use. |

| Trim/Molding | Penetrates surfaces well for strength. | Fills gaps on non-porous trim materials. |

| Panel Construction | Requires even pressure application. | Self-levels on uneven surfaces/seams. |

| Rapid Prototyping | Needs time to fully cure. | Immediate handling strength. |

| Reinforcing Joints | Strong but flexible. | More rigid reinforcement at stress points. |

Wood glue provides a stronger, more flexible bond ideal for indoor furniture, cabinets, and fine woodworking joints that need wood movement. Liquid nails is generally more suitable for outdoor structures and applications requiring an immediately

Wood Glue Vs. Liquid Nails in Furniture

| Furniture Type | Wood Glue | Liquid Nails |

|---|---|---|

| Chairs/Stools | Excellent for frame joints that need flexibility. | May be too rigid for stress points on frames. |

| Tables | Best for tabletops and x-frame joinery. | Fills gaps on legs/aprons but less flexible. |

| Cabinets | Ideal for casework and drawers where flexibility is needed. | Also suitable, fills gaps well on boxes. |

| Beds | Strong bonds for joints that experience movement. | Consider wood glue for slats/joints. |

| Bookcases | Penetrates well for carcasses and shelves. | Also works but wood glue favors flexibility. |

| Entertainment Centers | Frames and panels benefit from wood glue strength. | Could work for panels/surfaces. |

| Window Seats | Provides durable flexible bonds. | Only if very rigid bond is needed. |

| Ottomans | Perfect for frame joinery and lid attachment. | Could work but wood glue is more flexible. |

Wood glue is generally best for furniture requiring strong, flexible bonds at joints – especially for chairs, tables, cabinets that experience wood movement. Liquid nails can work but wood glue may provide better long-term durability in furniture applications.

Wood Glue Vs. Liquid Nails in Cabinets

| Cabinet Component | Wood Glue | Liquid Nails |

|---|---|---|

| Frames/Carcases | Excellent for strong, flexible joints. | May be too rigid over time with movement. |

| Face Frames | Penetrates well for durable bonds. | Also suitable, fills gaps on surfaces. |

| Drawers | Ideal for joining sides/fronts/backs that expand/contract. | Could work but wood glue favors flexibility. |

| Doors | Provides strength that endures wood movement. | Sufficient if movement isn’t a concern. |

| Shelves | Deep bonding for weight-bearing surfaces. | Works as well but wood glue bonds more flexibly. |

| Toe Kicks/Aprons | Strong, pliable joints to resist impacts. | Also suitable to fill gaps on attachments. |

| Crown Molding | Penetrates profile well for a tight grip. | Fills gaps where wood glue can’t reach. |

| Hardware Attachment | Durable bonds that flex with the wood. | Immediate strength but more rigid over time. |

Wood glue is best for cabinetry where flexibility is important, especially at joints of frames, drawers and doors that experience wood movement. But liquid nails also works well for filling gaps, attaching surfaces, and reinforcing hardware.

Durability and Longevity

The longevity of the bond between wood glue and liquid nails can be affected by environmental factors such as moisture, temperature, and exposure to chemicals. Wood glue is typically more susceptible to moisture, which can cause the bond to weaken over time.

In contrast, liquid nails are generally more resistant to moisture and can maintain their bond strength in damp conditions.

Strong Bond Conditions

To achieve the strongest bond possible between wood glue and liquid nails, you must follow certain guidelines:

- Surface Preparation: Ensure the surfaces to be bonded are clean, dry, and free of debris, grease, or dust.

- Appropriate Adhesive: Choose the proper adhesive for your specific materials and project requirements.

- Application: Apply the adhesive according to the manufacturer’s instructions, ensuring even coverage on both surfaces.

- Clamping or Fixing: If necessary, use clamps or other tools to maintain pressure on the bond while the adhesive cures.

- Curing Time: Allow for ample curing time, as recommended by the manufacturer, to achieve the strongest bond possible.

Conclusion

To make the best choice between wood glue and liquid nails, consider your project’s specific requirements and conditions. For most woodworking projects requiring a strong, durable bond, you may want to choose wood glue. However, if your project requires versatility, the ability to bond different materials, or a flexible adhesive, you might consider using liquid nails.

If you’re solely working with wood, wood glue might be the best option due to its compatibility and strong bond. For projects involving a variety of materials or requiring greater flexibility, Liquid Nails could be the better choice.

While Liquid Nails is versatile, it may not be the best choice for all woodworking projects. Wood glue is often preferred for its strong, durable bond, especially in structural applications.

Liquid nails generally perform better than wood glue on outdoor projects like decks and sheds since it is more water-resistant and withstands weather fluctuations better over time.

Liquid nails has self-leveling properties that allow it to fill gaps more uniformly on irregular or non-fitting surfaces, like attaching panels or trim materials with uneven edges.

Both adhesives can work with various wood types, but the specific project requirements and wood characteristics may influence the choice. Some applications may favor one adhesive over the other.