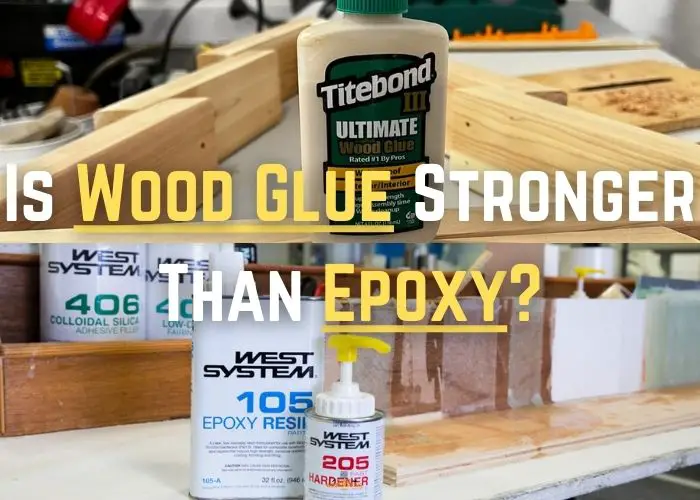

Is Wood Glue Stronger than Epoxy? Finally Answered!

When you’re working on a woodworking project, one of the most critical choices you will make is selecting the right adhesive. The decision often comes down to two popular options: wood glue and epoxy. Both adhesives have their own set of benefits and limitations, and understanding these factors will help you choose the appropriate adhesive for your project.

No, epoxy forms a stronger bond. It chemically bonds to wood at a molecular level, fully integrating. This creates an extremely durable moisture and stress-resistant seal. Wood glue relies on a weaker physical bond prone to failure over time. Testing shows epoxy’s tensile strength is 2-3x greater, 3000-4000 PSI vs 800-1500 PSI for wood glue. Epoxy is recommended for structural joints, moisture areas, or bonding different materials, while wood glue suits most indoor/non-structural applications not requiring maximum strength or weather resistance due to its easier workability.

Generally, epoxy is stronger than wood glue for bonding wood. Epoxy forms a very strong chemical bond with wood, forming a waterproof and heat-resistant seal. The molecules of epoxy literally fuse together with the wood at a molecular level, making the bond incredibly strong.

Wood glue relies on a physical bond instead of a chemical one. While modern wood glues like Titebond III are very strong, the adhesive bond is not as thoroughly integrated into the wood structure as an epoxy bond. Wood glue joints are prone to eventually failing if exposed to long-term stresses or moisture. Epoxy bonds maintain their strength long-term even in wet conditions.

There have been studies that tested the strength of different adhesives joining wood. According to this source, epoxy has a tensile strength between 4,000-6,000 PSI, making it significantly stronger than typical wood glues that fall in the 3000-4000 PSI range. Epoxy truly forms the strongest possible bond between wood surfaces or other materials.

However, wood glue is still an excellent choice for many applications that don’t require maximum strength or resistance to weathering. It is easier to work with than epoxy and more forgiving if adjustments need to be made. For general indoor furniture construction and light-duty outdoor projects, wood glue is sufficient. But for applications that involve long-term structural stresses, moisture exposure, or bonding different material types, epoxy is the better choice for its unparalleled durability and strength.

With good technique, wood glue can certainly achieve durable joints for furniture and other indoor projects. But in situations where gaps need filling, or projects will see long-term moisture exposure, the unparalleled strength of epoxy makes it the clear choice.

In the end, while wood glue has its place, epoxy should be your go-to for any application where absolute maximum bond strength is a priority. From complex gap-filling repairs to heavy-duty outdoor structures, I’ve seen first-hand how epoxy consistently excels when strong, long-lasting performance is what truly matters.

In conclusion, for precision-fitted joints and traditional woodworking, wood glue might be the go-to option. For projects demanding structural strength, versatility, and waterproof characteristics, epoxy could be the preferred adhesive.

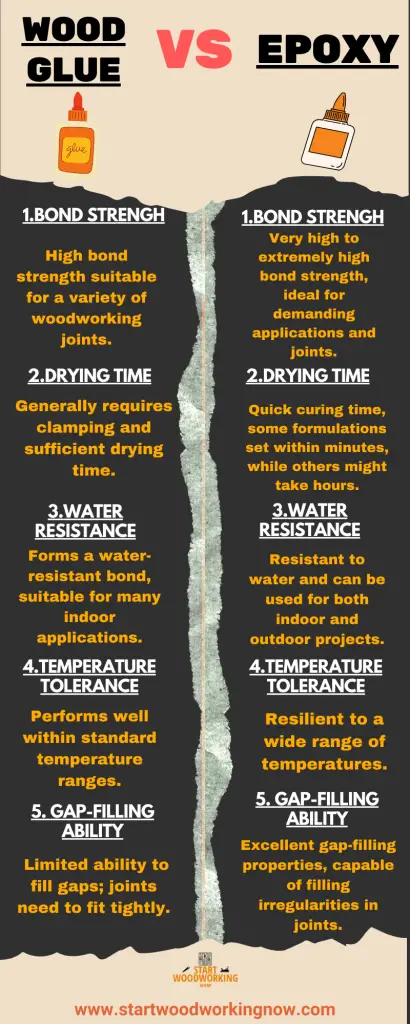

Wood Glue vs Epoxy: Bond Strenght

| Joint Type | Suitable Adhesive | Notes |

|---|---|---|

| Butt joints | Epoxy | Epoxy fully fills gaps for a strong structural bond. |

| Edge-grain joints | Wood glue | Wood glue provides a strong bond for non-structural joints. |

| Face-grain joints | Epoxy | Epoxy penetrates end grain better than wood glue for structural joints. |

| Miters | Epoxy | Epoxy is resistant to seasonal wood movement to prevent cracks. |

| Splines/biscuits | Wood glue | Wood glue bonds well to reinforce edge-grain joints. |

| Cross-grain joints | Epoxy | Epoxy forms the strongest bond across wood grain. |

| Joints under stress | Epoxy | Epoxy maintains strength under long-term structural stresses. |

| Outdoor joints | Epoxy | Epoxy forms the strongest bond across the wood grain. |

When comparing the inherent bonding strength of wood glue and epoxy, epoxy creates a stronger bond. Tests have shown that epoxy routinely forms bonds that are 2-3 times stronger than wood glue. On average, wood glue can achieve bonding strengths of around 150 pounds per square inch.

Epoxy, however, is capable of bond strengths ranging from 3000 to 4000 pounds per square inch or more. The chemical reaction that occurs when epoxy cures allows it to better adhere to a wider variety of surfaces than wood glue. It bonds not only to wood, but also to materials like metal and stone that wood glue cannot join.

While factors like wood type, joint design, application technique, and environment play a role, epoxy forms a tougher and more rigid bond than flexible wood glue. For applications requiring maximum strength transfer across a bond line, epoxy provides inherently stronger performance than wood glue. In situations demanding high structural strength, epoxy is generally the superior choice of

Wood glue is a common choice among woodworkers due to its ease of use, availability, and strong bonds with wood surfaces. It is specifically formulated for wood and contains ingredients that allow it to penetrate the wood fibers, creating a strong and lasting bond.

In contrast, epoxy is a versatile adhesive that can bond various materials, including wood, metal, plastic, and ceramic. It is typically a two-component system, mixing a resin and a hardener, which cures to form an extremely durable bond.

When choosing between wood glue and epoxy, it is essential to consider the specific requirements of your project, such as the materials being bonded, exposure to moisture, and the need for gap filling. For example, epoxy may be a better fit when you need to fill gaps or bond non-wood materials, while wood glue’s strength and compatibility with wood make it an ideal choice for projects that solely involve wooden surfaces.

Another factor to consider is the durability of the bond. Wood glue is known for being moisture-resistant, but not entirely waterproof, and may deteriorate under extreme environmental conditions. Epoxy, on the other hand, is both waterproof and resistant to chemicals, making it a more suitable option for projects exposed to harsh conditions.

Comparing Wood Glue and Epoxy

Here is a comparison of wood glue vs epoxy from my woodworking expert’s perspective:

| Characteristic | Wood Glue | Epoxy |

|---|---|---|

| Curing Time | Slower curing time; requires clamping | Faster curing time; sets quickly, especially epoxy putty |

| Water Resistance | Resistant to moisture but not waterproof | Generally waterproof, making it suitable for submerged applications |

| Temperature Tolerance | Limited resistance to extreme temperatures | Resistant to a wide range of temperatures; suitable for both hot and cold environments |

| Gap-Filling Qualities | Requires tight joints for optimal bonding | Excellent gap-filling capabilities, ideal for uneven or irregular surfaces |

| Strength of Bond | Strong bond for well-fitted joints | Exceptionally strong bond, especially in load-bearing or stressed applications |

| Versatility | Primarily for wood-to-wood bonding | Versatile; bonds various materials including wood, metal, plastic, etc. |

| Transparency | Dries clear, but the bond may be visible | Can be formulated to create transparent or colored finishes |

| Application Time | Sufficient time for adjustments during clamping | Limited working time; attention to application precision is crucial |

| Ideal Use Cases | Woodworking projects with well-fitted joints | Versatile applications, including heavy-duty repairs, multi-material bonding, and gap filling |

| Common Applications | Furniture assembly, joinery, woodworking | Automotive repairs, bonding metal and plastic, structural reinforcements |

Drying Time

The drying time of wood glue depends on factors such as humidity and the amount of glue applied, which typically ranges from 24 to 48 hours. On the other hand, epoxy often takes less time to dry, usually setting within 5 to 60 minutes. However, epoxy’s full strength might need 24 hours to develop.

Flexibility

Wood glue is flexible, allowing for some wood movement in response to temperature and humidity changes, which is essential for woodworking applications. In contrast, epoxy produces a rigid bond, making it suitable for applications where flexibility is not required, such as in wood waste-based composites.

Water Resistance

Once fully cured, wood glue forms a water-resistant bond suitable for indoor/outdoor use. Epoxy provides superior water and moisture resistance, forming very durable long-term bonds even in wet conditions.

Suitability for Projects

Wood glue is ideal for woodworking projects, such as furniture making, where pieces require strong adhesion and can be clamped until the glue dries. In contrast, epoxy’s versatility makes it suitable for various projects, including marine and outdoor applications where moisture resistance and strength are essential.

Application

Wood glue is easy to use, cleans up with water. It requires tight joints and clamping. Epoxy fills gaps extremely well, adheres to many surfaces, but requires more precise application and can be difficult to remove if uncured.

Durability

Wood glue bonds are very durable, lasting decades with proper use. The flexible bond allows for wood expansion and contraction. Epoxy bonds are extremely durable due to resistance to temperatures, moisture, and chemical damage. However, an epoxy bond is more brittle and can fail if stresses from wood movement are applied.

Safety

Wood glue is non-toxic when dry and cleans up easily. Epoxy resins and hardeners require safety equipment like gloves and ventilation due to chemical fumes. Proper curing of epoxy eliminates most risks.

When to Use Wood Glue

- Wood-to-Wood Joints:

- Wood glue is specifically designed for bonding wood to wood, providing a strong and reliable connection.

- Structural Wood Projects:

- Ideal for applications where a robust and durable bond is required, such as in furniture construction, cabinets, and wooden frames.

- Longer Clamping Time Needed:

- When a longer working time is essential for precise alignment and adjustments during the clamping process.

- Water-Resistant Outdoor Projects:

- Suitable for projects exposed to outdoor conditions, as wood glue forms a fully water-resistant bond when cured.

- Flexibility Requirement:

- In situations where a degree of flexibility in the bond is desired, as wood glue remains flexible under stress.

- Ease of Application:

- For projects that require a straightforward and user-friendly adhesive application without the need for complex mixing.

- Minimal Safety Concerns:

- When safety and ease of use are a priority, as wood glue, especially water-based formulations, tends to have minimal health risks.

- Projects with Limited Exposure to Harsh Environments:

- In scenarios where the bonded materials won’t be subjected to extreme temperatures, chemicals, or excessive stress.

- Budget-Friendly Applications:

- Wood glue is often more cost-effective than epoxy, making it a preferred choice for budget-conscious projects.

- Educational and Hobbyist Woodworking:

- Suitable for educational purposes and hobbyist woodworking due to its simplicity and ease of use.

In summary, wood glue is best for indoor furniture while epoxy excels for outdoor use, gap-filling, strength or situations requiring maximum durability.

When to Use Epoxy

- Versatile Material Bonding:

- Epoxy is suitable for bonding a wide range of materials beyond wood, including metals, plastics, ceramics, and more.

- High-Strength Requirements:

- In applications where an exceptionally strong bond is needed, especially in load-bearing or high-stress situations.

- Gap Filling:

- Epoxy is effective for filling gaps and irregularities between materials, providing a strong, seamless bond.

- Quick Curing and Setting:

- When a fast-setting adhesive is required, epoxy typically cures more quickly than traditional wood glue.

- Waterproof Bonds:

- Epoxy bonds are generally waterproof, making them suitable for applications where the bonded materials will be exposed to moisture.

- Chemical and Temperature Resistance:

- For projects requiring resistance to chemicals, heat, or extreme temperature variations, epoxy is a more resilient choice.

- Transparent or Colored Bonds:

- When a clear or tinted bond is desired, epoxy can be formulated to create transparent or colored finishes.

- Heavy-Duty Repairs:

- Ideal for repairing heavy-duty items, such as automotive components, fiberglass, or other materials that require a robust bond.

- Artistic and Decorative Projects:

- In situations where the adhesive will be visible and part of the design, epoxy’s clear finish is advantageous.

- Wood Joinery Reinforcement:

- Epoxy can be used to reinforce and strengthen wood joinery, providing additional structural support.

Is wood glue stronger than epoxy for woodworking?

In my experience, epoxy is often considered to be stronger than wood glue for woodworking projects.

Wood glue is ideal for non-load bearing furniture, modeling, and picture frames where long-term durability is not critical. However, for projects that will see weathering or repeated stress, epoxy provides unmatched adhesion. Epoxy penetrates the wood to form a chemical bond, while wood glue relies on surface contact alone.

From my woodworking experience, epoxy truly shines for outdoor structures, large cabinets and heavy-duty joinery. The molecular bond epoxy forms is resistant to water damage and pressure that can cause wood glue joints to fail over decades. Applications like deck building, boat construction, and structural joinery demand maximum strength – for these, epoxy delivers bonds that truly stand the test of time.

| Project Details | Recommended Adhesive |

|---|---|

| Indoor furniture from solid wood boards/panels | Wood glue – allows for wood movement, easy application/cleanup |

| Outdoor furniture/projects | Epoxy – superior water and weather resistance |

| Large wood surfaces/panels with gaps to fill | Epoxy – excels at filling gaps up to 1/2” |

| Non-wood materials (metal, stone, composites) | Epoxy – bonds many surfaces wood glue cannot |

| High structural stress/load-bearing joints | Epoxy – stronger and more rigid bond |

| Small delicate repairs/intricate assemblies | Wood glue – more precise control of application |

| Tight joints between solid wood pieces | Wood glue – penetrates wood fibers for strong bond |

| Joints that may need to be disassembled | Wood glue – reversible bond allows future repairs |

| High temperature/chemical exposure | Epoxy – greater heat/chemical tolerance |

| Marine/nautical projects | Epoxy – waterproof and resists moisture absorption |

| Porous/low-density woods (balsa, pine) | Epoxy – fills voids wood glue cannot bridge |

| Hardwoods with minimal gaps (oak, maple) | Either – wood glue often sufficient for strength |

Is wood glue stronger than epoxy for furniture?

As a woodworker with decades of experience, I’ve seen that wood glue works well for non-structural furniture joints that experience little stress. However, epoxy creates stronger, more durable bonds better suited for furniture intended to last.

Epoxy fully penetrates the wood grain, allowing it to effectively transfer stresses without failing. Its chemical bond also makes it resistant to humidity changes that can cause wood glue joints to crack.

For furniture taking heavy use like chairs, Epoxy bonds are nearly as strong as the wood itself. While more difficult to apply, the increased durability of an epoxy bond is worthwhile for any furniture piece wanted in the home for many years.

Whether bonding table bases, entertainment centers, or chair seats, I’ve found these joints undergo more stress and movement than others. Epoxy fills gaps completely and fuses at a molecular level, forming exceedingly strong, long-lasting bonds. Its rigidity prevents cracks better than wood glue over decades of use. In turn, furniture joins bonded with epoxy can endure heavy family use.

Frequently Asked Questions

Epoxy is best for structural outdoor projects, joints that will experience repeated stresses, situations involving different material types, or when a waterproof bond is needed.

Epoxy excels at filling gaps due to its viscosity and adhesive properties, making it superior for projects with irregular joint surfaces.

The downsides to epoxy include being more expensive, requiring caustic chemicals for cleanup, longer setting and curing times, and limited pot life once mixed. Gluing more later requires accuracy in mixing more resin and hardener. Some varieties of epoxy may also require a respirator to work with.

Yes, you can apply epoxy over an existing wood glue joint. Just be sure to clean and roughen the surfaces first for the epoxy to bond effectively.