Is Wood Glue Waterproof When Dry? The Ultimate Guide!

As woodworkers, one of the most common questions we grapple with is whether wood glue maintains its bond once fully cured or if it degrades when exposed to moisture.

Yes, wood glue can be waterproof or water-resistant depending on the type of glue. Polyurethane glue is waterproof and suitable for outdoor projects, while cross-linking PVA glue is water-resistant and ideal for indoor use. Epoxy glue is also waterproof and suitable for marine applications. The ANSI/HPVA Type 1 and Type 2 certifications indicate the waterproof and water-resistant capabilities of wood glues. Type 1 is almost entirely waterproof, while Type 2 is water-resistant in most cases.

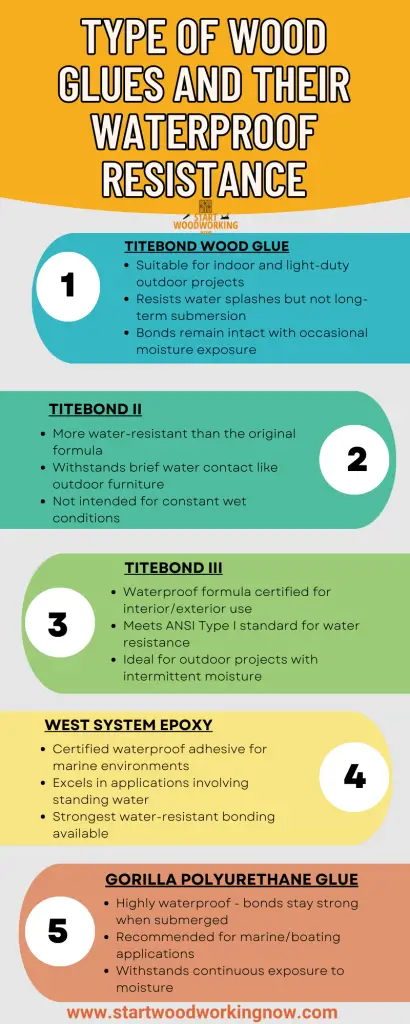

Which types of wood glue are waterproof/water-resistant when dry?

As a woodworker, I know that choosing the right type of wood glue is crucial for a successful project. There are different types of wood glue available on the market, but not all wood glue is waterproof. Some types of wood glue are water-resistant, while others are not:

| Glue Type | Water Resistance | Suitable Applications | Bond Strength |

|---|---|---|---|

| Polyurethane (Gorilla, etc) | Highly Waterproof | Boat building, outdoor furniture, planters – withstands long term submersion. | Very Strong |

| Epoxy (West System, etc) | Highly Waterproof | Boat building, water features – certified waterproof for marine use. | Very Strong |

| Titebond III | Waterproof | Interior/exterior projects requiring occasional moisture exposure – meets ANSI Type I standard. | Strong |

| Titebond II | Water Resistant | Interior/exterior projects sheltered from constant moisture – resists brief water contact. | Strong |

| Titebond I | Water Resistant | Interior projects, light duty exterior use – not suitable for prolonged moisture exposure. | Strong |

| Elmer’s Glue-All | Not Water Resistant | Basic indoor woodworking only – bond will degrade with moisture. | Adequate |

| Cyanoacrylate (CA) Glue (Super Glue) | Some water resistance | Indoor projects, bonding small surfaces, prototypes – not suitable for prolonged submersion. | Very Strong initially, but brittle long-term |

Key things to note when selecting a glue:

- Polyurethane and epoxy are most waterproof once fully cured

- Consider your project’s water exposure level

- Follow manufacturer drying times for maximum resistance

- Surface preparation and application technique matter

- No glue maintains strength under constant long-term submersion

However, prolonged exposure to water can compromise the glue’s strength and cause it to break down.

1. PVA/Titebond Glues

PVA (polyvinyl acetate) glue, also known as white glue or school glue, is one of the most popular types of wood glue. It is water-resistant and perfect for indoor projects that do not require water resistance. PVA glue forms a strong bond and is easy to use. Titebond is a popular brand of PVA glue that is known for its durability and strength.

The glue is absorbed into the wood fibers and forms a strong bond as it cures. As the glue dries, it releases water, which is absorbed by the wood. This process causes the glue to shrink and create a tight bond between the two surfaces.

2. Epoxy

Epoxy is a two-part adhesive that is known for its resistance to water and other chemicals. It is resistant to weather and can be used for outdoor projects.

Epoxy consists of a resin and a hardener that are mixed together to create a strong bond. It is ideal for bonding wood to other materials, such as metal or plastic.

3. Polyurethane Glue

Polyurethane glue, also known as Gorilla Glue, is a waterproof glue that is perfect for outdoor applications. It is durable and can withstand extreme weather conditions.

Polyurethane glue is moisture-activated, which means that it expands as it dries, creating a strong bond. It is ideal for bonding wood to wood or other materials.

4. Cyanoacrylate Glue

Cyanoacrylate glue, also known as super glue, is not waterproof. It is a fast-drying adhesive that forms a strong bond but is not recommended for outdoor use or projects that will be exposed to moisture.

In conclusion, PVA/Titebond glues are great for indoor projects, while epoxy and polyurethane glues are more durable and waterproof, making them ideal for outdoor projects.

How can you identify waterproof wood glues?

Here are some steps to identify waterproof wood glues:

- Check the Manufacturer’s Claims – Look for terms like “waterproof”, “water resistant”, or “marine” on the glue label or product page. Reputable brands will clearly state water resistance properties.

- Consider the Chemistry – Polyurethane glues are generally the most waterproof as they form a durable chemical bond. Epoxies are also very water-resistant once fully cured. Avoid plain PVA/Titebond for water applications.

- Review Independent Testing – Search online for third party glue tests that compare water resistance, such as how long bonded joints withstand submersion. This can confirm manufacturer claims.

- Inspect Active Ingredients – Waterproof glues will contain hydrophobic chemicals that repel water molecules. Check product MSDS/TDS sheets to ID key ingredients like polyurethane or epoxy resins.

- Check the product information for details on the recommended drying and curing times. Waterproof wood glues may have longer drying times or curing periods.

- Cure a Sample Joint – Apply the glue between scrap wood, allow full cure, then submerge in a bucket of water for 24-48 hours. Waterproof glues should show no signs of delamination or degradation.

- Consult Experts – Talk to other woodworkers experienced with marine/exterior applications. They can recommend glues proven to withstand long term moisture exposure.

Here are some of the main certifications and standards related to testing and verifying the waterproof/water-resistant properties of wood glues:

- ANSI/HPVA Type I – Developed by the Hardwood Plywood & Veneer Association, this is one of the most common standards for water-resistant wood glues in North America. It requires glued joints to withstand 24 hours of water submersion without delaminating.

- EN 204/D4 – A European standard (EN 204) that establishes durability classes (D1 to D5) based on resistance to water and other factors. Class D4 is the highest rating, indicating waterproof performance even after long-term exposure.

- ASTM D5572/D5573 – ASTM International standards that test wood glues specifically for exterior applications. They evaluate properties like resistance to ultraviolet light, water immersion, heat aging, and more.

- Marine Epoxy Certification – Epoxy resin manufacturers may obtain certifications confirming a product’s suitability for marine/boat building according to ASTM standards. This ensures strength and longevity under water.

- LEED Certification – The LEED green building rating system awards points for using glues that meet ANSI/HPVA or ASTM exterior standards, recognizing their reduced environmental impact.

- SGS Testing & Certification – An independent laboratory that performs standardized testing on glues to certify water resistance ratings according to global standards like EN 204 Class D4.

Proper Application Techniques for Waterproof Wood Glue

Here are steps to ensure the effective application of waterproof wood glue:

- Surface Preparation: Sand surfaces smooth and remove any dirt/debris. For porous woods, raise the grain with fine sandpaper and wipe clean.

- Apply Thin, Even Coat: Use a high-quality brush or roller to spread the glue in an even, thin layer over both surfaces. Too much glue can weaken the bond.

- Clamp Tightly: Apply sufficient clamping pressure to squeeze out excess glue and bring surfaces into full contact. This is critical for epoxies and polyurethanes.

- Allow Full Cure: Follow manufacturer cure times, usually 24 hours or more for waterproof glues. Avoid disturbing the joint until fully set.

- Water Testing: For critical applications, test sample joints by submerging in a bucket of water for 2 days before use.

- Filling Gaps: Epoxies and polyurethanes can be thickened for gap-filling. Apply in layers for gaps over 1/8″.

- Dry Completely Before Use: Waterproof glues may still be curing on the inside for weeks. Let bonded projects dry fully before prolonged moisture exposure.

Proper surface prep and applying/curing waterproof glues as directed by the manufacturer will yield joints that withstand long term submersion.

How long does the glue need to fully cure/dry before it achieves waterproof properties?

The drying time and curing time are also important factors to consider when applying wood glue. Drying time refers to the time it takes for the glue to dry to the touch, while curing time refers to the time it takes for the glue to fully cure and create a strong bond.

| Glue Type | Cure Time to Achieve Waterproof Bond |

|---|---|

| Epoxy (West System, etc) | 24-48 hours |

| Polyurethane (Gorilla, etc) | 24-48 hours |

| Titebond III | 24 hours |

| Titebond II | 24 hours |

| Titebond I | 24 hours |

| Elmer’s Glue-All | 12-24 hours |

Insights from My Hands-On Tests and Reviews

I have tested various wood glues to find the best ones that provide both strength and durability. In this section, I will provide insights from hands-on tests and reviews and highlight specific wood glues rated for indoor and outdoor use.

In my experience, the best wood glue is one that is easy to apply, dries clear, and provides a strong bond. One of the most popular wood glues is Titebond Original Wood Glue, which is ideal for indoor projects. It has a strong initial tack and dries quickly, making it easy to sand and stain. Plus, it is water-resistant and can withstand heat and solvents.

If you need a wood glue for outdoor projects, Titebond II and III Ultimate Wood Glue are excellent choices. Both are waterproof and provide a strong bond that can withstand extreme temperatures. Titebond III is the most durable and can be used for projects that require maximum strength.

Another wood glue that I highly recommend is Gorilla Wood Glue. It is versatile and can be used for indoor and outdoor projects. It dries clear and is water-resistant, making it perfect for projects that may be exposed to moisture.

Frequently Asked Questions

Whether the glue can withstand getting wet depends on the type. Epoxies and polyurethanes maintain bonding when wet, while others may degrade with prolonged moisture exposure.

In general no, gluing wet wood is not recommended. The moisture content needs to be stable for a durable bond. It’s best to allow boards to fully air dry before gluing to avoid bonding failures

While finishes provide some protection from moisture, they do not make regular wood glue fully waterproof. Epoxies or polyurethanes are stronger choices for projects that will see long-term wet conditions even when painted/stained.