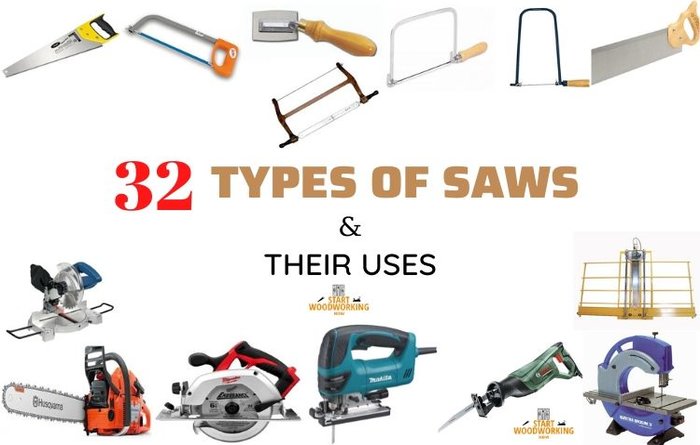

32 Types of Saws and Their Uses

Circular saw, table saw, band saws or miter saw? Fixed or mobile? For detail work or rough cutting? Find out in this article what type of saws you can buy and where each types of saws have different and multiple uses.

The most common questions that arise are those about the saw because they are complex work equipment.

One of the most common tasks in most craft projects is the cutting or cutting of different materials, often in the form of sawing.

Whether wood, metal or plastic, sawing is a popular method of bringing a wide variety of materials into the required shape and size.

Some types of saws are therefore mainly found in professional use and in industry and an acquisition for private use rarely makes sense.

A main distinguishing criterion for saws of all types is the type of their power. Other types of saws, however, can be used universally and are therefore widely used.

In this post, I will present you 32 Different Types of Saws and Their Uses.

| Types of Saws |

|---|

| 1. Hand Saw |

| 2. Back Saw |

| 3. Fine Saw |

| 4. Bow Saw |

| 5. Coping Saw |

| 6. Crosscut Saw |

| 7. Japanese Saw |

| 8. Hacksaw |

| 9. Frame Saw |

| 10. Jab Saw |

| 11. Veneer Saw |

| 12. Fretsaw |

| 13. Pruning Saw |

| 14. Drywall Saw |

| 15. Two-man Saws |

| 16. Electric Circular Saw |

| 17. Jigsaw |

| 18. Plunge Saw |

| 19. Alligator Saw |

| 20. Saber Saw |

| 21.Reciprocating Saw |

| 22. Chainsaw |

| 23. Electric Circular Table Saw |

| 24. Band Saw |

| 25. Miter Saw |

| 26. Compound Miter Saw |

| 27. Multi-blade Electric Saw |

| 28. Scroll Saw |

| 29. Radial Arm Saw |

| 30. Panel Saw |

| 31. Plunge Saw |

| 32. Tile Saw |

Different Types of Saws :

To help you when using saws in your activities, we have prepared a list of the most used types of saws:

15 Different Types of Hand Saws :

A distinction is made between hand-operated saws, their size and weight and, last but not least, their performance are limited by the use of simple muscle power of the craftsman and motorized models, which are also referred to as sawing machines.

Hand saws are rarely used these days – the electric types of saw are faster, more convenient and work costs significantly less power.

The hand saws usually work pushing, which means that the saw teeth remove the material when pushing.

However, a good fox tail saw or a fine saw should actually be in every tool box. You can read about the different types of hand saws in this article.

We will examine different types of hand saws before we proceed at the next type of saw category.

1.Hand Saws

Hand saws have evolved as needed. Some of them are considered general-purpose tools, such as a traditional hand saw, while others were designed for a specific purpose.

This types of saws are designed for cutting raw wood. The gaps between the teeth are necessary so that the wet chips do not clog the cut and can be easily removed during work.

No set of tools will be complete without at least one of them, while individual craftsmen can purchase exactly those tools that meet their individual needs, for example, for framing or decoration.

Uses of Hand Saws:

- the hand saw is intended for cutting solid wood plates and boards, chipboards, etc.

2.Back Saw

A back saw is a relatively short type of saw with a narrow blade that is reinforced along the top edge.

The back saw is a cutting tool with a strip of steel or brass running along the back of the knife.

This area is called “back”. The weight of the back and the sharp, serrated teeth make the rear saw blade good for cutting wood.

Back saws should always be used with a clamp or vise. To cut joints in the wood, a carpenter or woodworker must first ensure that his project is firmly clamped, and then use his index finger to grasp the handle of the rear saw over the top of the saw blade for additional support.

The first cuts should be made gently, with the blade sweeping away from the body. After a groove is made, it becomes easier to move back and forth in the traditional saw motion.

Uses of Back Saw:

- In fact, back saws are typically used to create joints or grooves in wood. They are a good choice for carpenters and woodworkers because they are versatile and efficient, and they are usually smaller than a table saw.

- Back saws are a commonly type of saw used for cutting at an angle and in areas where a constant, direct, direct cut is required.

3.Fine Saw

Another type of hand saw is the Fine Saw.

The saw blade of the fine saw is relatively thin and rectangular in shape. A bar on the top gives the narrow leaf the necessary stability.

The handle is often slightly offset so that you can also saw along edges. With the fine saw, straight and precise cuts can be made.

4.Bow Saw

Another type of crosscut saw, the bow saw, is used more often on the outdoor than inside home.

It uses a relatively long blade with numerous transverse teeth designed to remove material when pushing and pulling. Bow saws are used for trimming trees, sawing logs, as well as various rough cuts.

The blade of a bow saw is stretched over a steel hoop. Bow saws are available with different teeth.

Uses of bow saw:

- Cut out the branches.

- Trimming trees

5.Coping Saw

Having a thin narrow blade, the copy saw is ideal type of saw for finishing work, rounding and any other types of cutting that require high precision and complex cutting operations.

Coping saws can be used to cut various materials, and they can be found in tool kits of various craftsmen, from carpenters and plumbers to manufacturers of toys and furniture.

6.Crosscut Saw

Designed for rough cutting of wood, the crosscut saw has a relatively thick blade with large beveled teeth. Traditionally, cross saws are made two-handed (so-called felling saws).

They have a handle at each end of the blade and are intended for use by two people to cut (perpendicularly) the trunk of a tree.

The less common type of one-handed cross-cut saw is great for coarse trimming of boards or branches and an excellent saw for fast trimming work on a construction site or in a forest.

Uses of Crosscut saw:

- A crosscut saw is a specialized type of handsaw used for manually cutting wood across the grain. Crosscut saws include a blade and a handle.

7.Japanese Saw

This type of saw from the Far East (in Japanese: Nokogiri) is also becoming increasingly popular in Europa and North America.

The blade is therefore relatively thin and, with its extremely sharp teeth, enables very fine cuts with little effort.

The main difference is that the Japanese saw works on a pull and the European saw works on a push.

The Japanese hand saw is thus pulled through the wood towards the body , while the European saw is pushed through the wood away from the body.

Saws that work on butt have a particularly wide and rigid saw blade , whereas Japanese saws use a particularly thin and flexible saw blade.

Uses of Japanese saw:

- Japanese saws are primarily used for the processing and processing of wood .

- On the one hand, it can be solid wood such as round wood or lumber, and on the other hand it can also be wood-based materials such as plywood or chipboard.

- Furthermore, Japanese saws can also be used for the processing and processing of various soft plastic materials such as PVC, ABS or GRP as well as for polystyrene .

- Under no circumstances may Japanese saws be used for metal, as this would damage the fine saw teeth.

8.Hacksaw

Ideal for cutting pipes and rigid hoses,hacksaw is one of the most common types of saws.

Being lightweight and versatile, hacksaws are capable of cutting wood, metal, plastic and other materials using cutting blades for various materials with the number of teeth from 18 to 32 per inch (from 7 to 13 per centimetre).

Uses of Hacksaw:

- the hacksaw is used to saw small pipes and light metal profiles.

9.Frame saws

The wooden construction of the frame saw, also called a tension saw, consists of 2 vertical bars (saw arm) and a saw bar, arranged in an H-shape.

The frame saw can be used universally: for cutting to length, trimming, slitting and setting down.

Stainless steel blade and pulse hardened, with teeth for fine cutting, ideal for green or dry wood.

The tip of the blade is sharp, for safe and trouble-free work in tight spaces. The blade can be replaced easily and quickly without tools.

Cutting to length is the cut across the grain to shorten a board. Trimming is the removal of the edge of the tree from the board, the cut goes length ways to the grain.

10.Jab saw

The jab saw (“alligator”) is also known in English-speaking countries as the “keyhole” (keyhole) is a round handle with one blade protruding from the top of the handle.

A jab saw is a type of saw used for rough cutting circles or patterns. It can be indispensable for drywall, especially when the cutting area is removed or inaccessible and the shape of the wall does not allow the use of power tools.

11.Veneer saw

The veneer saw is used to cut veneers, which are 0.4 to 0.6 mm thick sheets of wood, which are separated from the trunk with a veneer cutting machine and which are glued or glued to a carrier material – block board, particle board or MDF board.

Veneer saws are not restricted! For cutting, the veneer is first placed on a flat table top made of wood-based material and a ruler (may be a wooden strip) is attached to the cut edge with screw clamps.

Then the veneer saw is pulled along the ruler, pressing the saw blade against the ruler with the left hand and pulling with the right hand.

12.Fretsaw

Fretsaw is another type of saw used for all fine work where you have to saw very precisely. With the fretsaw, shapes made of wood can be sawed out very precisely, also because of the thin saw blades.

The fretsaw, very similar to a copy saw, has a long thin blade used for complex cuts.

The fretsaw has a longer and larger frame, which allows you to cut further from the outer edges, but the blade cannot rotate, which leads to more tiring and difficult conditions when performing complex cutting.

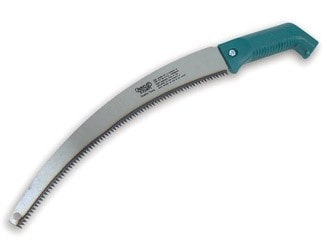

13.Pruning saw

The pruning saw strongly resembles a knife, but with a slightly curved blade that allows you to saw in the right angle, quickly and easily.

The teeth are arranged in such a way that the saw cuts during the withdrawal movements, which is advantageous when working at a height above the head.

The carbon metal blade is stainless. You can extend the saw by screwing a wooden prop into the handle.

Uses of Pruning saw:

- cutting branches difficult to reach or selective cutting, which is not possible mechanically.

14.Drywall saw

Outwardly similar to a jab saw, a drywall saw typically has a shorter and wider blade and fewer teeth per inch and is often executed as a forked edge.

Drywall saw is designed to be pierced through panels or drywall and is sometimes used to create initial holes for power tools.

15.Two-man saws

These large types of saws, also known as “farm saws” or “forest saws”, which are operated by two men, were mainly used for forest work. Today they are no longer used – except for the maintenance of traditions.

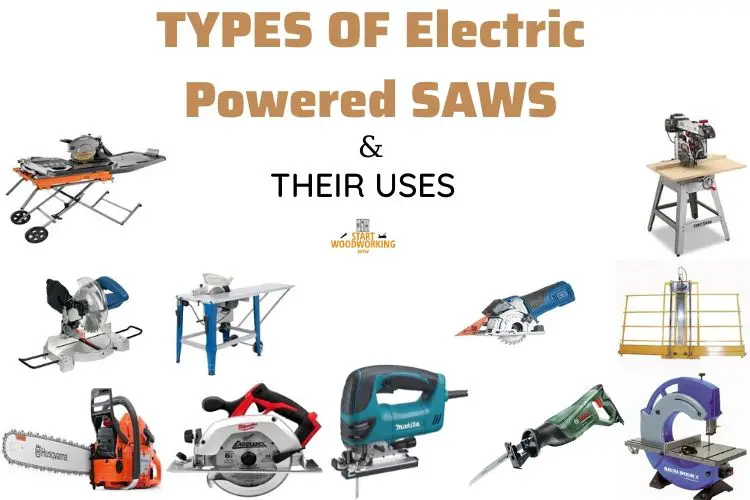

Different Types of Electric Power Saws :

Electric saws, also called machine powered saws, work either via a power connection or a battery.

The possibilities of a hand-operated saw are limited.

Machines are used wherever muscle strength and endurance are not sufficient.

Numerous specialized, mostly electric sawing machines have been developed in the course of the craft history, some of which are widely used, both in the professional and in the DIY sector.

Basically, sawing machines are differentiated according to how they are operated.

We will look at the most common types of electric saws to get an idea of their working capabilities and application features.

The engine of many chainsaws, on the other hand, requires fuel.

Now we will present the main types of electric power saws that exist today and their uses.These electric power saws presented below are particularly popular.

Depending on the type of cutting and the work to be done, you can have these types of saws:

- Handheld electrical power saws

- Electric bench power saws

9 Handheld electrical type of power saws:

Different types of circular saws are used in wood processing workshops, depending on the specific operations they can perform.

The types of circular saws that we present to you is addressed to both amateur users and professional users of woodworking workshops with mass production.

1.Electric Circular Saw

This saw model uses a disc-shaped blade, provided with sharp teeth, which rotates around a shaft, making precise cuts in a variety of materials.

It can be used to make straight line sections or following a curved path, providing good stability over long distances. But it is less suitable if it is small cuts, sharp angles or tight curves.

The electric types of saws are available in models with cable power, more powerful and recommended for professionals, and respectively, in variants with battery, easier to handle, optimal for hobbyists of DIY projects.

It works very well with almost any material, from wood planks to metal sheets and concrete, if you choose the right blade and you bought a quality model, with a power of over 1.7kW.

Uses of Electric Circular Saw:

- Ideal for all work on site and / or in the workshop. Perfect for carpenters, cabinetmakers.

- The circular saw can also be used for miter sawing, using the guide supplied to obtain straight cuts.

For example, there is an indication on the machine that allows you to miter at 45 °. There are also models for sawing thin metal plates, obviously using a suitable blade.

2.Jigsaw

The jigsaw is also an all-rounder type of power saw that is used in many areas. It can be used to cut wood or plaster.

Such models can also be used outdoors and indoors. In addition, they are particularly handy and compact, which makes their use as convenient as possible.

Due to its small size, the engine is not particularly strong. In addition, the saw blade is relatively thin, which is why jigsaws cannot cut harder materials such as concrete or stone.

But it can also work very precisely with such models. After all, you can also make round cuts with the thin saw blade.

In addition, many different saw blades are sold, with which the device can be adapted to different purposes and materials.

These versions are available in cable and battery versions, respectively, in small, easy to handle and stored formats.

They belong to the category of models with manual support, so the saw is moved along the sectioning path, and the material is in place, well fixed.

Uses of Jigsaw:

- The jigsaw makes it easy to saw curved lines or other flowing shapes in wood, synthetic materials, metal and even tiles (special blade).

- For a clean cut, it is necessary to disconnect the pendulum function (for example for thin plates).

- For hard materials, it is advisable to start by drilling a hole inside the part to be sawn.

- A jigsaw is exactly what you need if you work frequently with projects that involve making fine cuts, in tight curves or sharp angles, with small brittle lines.

- It can also be used to cut a piece, of any shape, from a larger wood or PAL board or MDF.

3.Plunge saw

In a wood processing workshop, situations may occur frequently where it is necessary to cut a piece of wood, longitudinally or crosswise.

For the different cuts of the wooden parts we can used successfully plunge saws models.

A plunge saws is a type of wood sawing machine provided with a circular disc that ensures cutting of the wood material on a straight axis.

Such a hand-held circular saw offers numerous advantages, being lightweight and allowing mobile use when appropriate.

These hand-held circular plunge saws models are recommended for use on construction sites or during assembly work.

These wood cutting saws are extremely useful to facilitate the processing operations quickly and without additional costs.

These types of wood saws can be used for cutting, cutting, chopping, angle cutting and inclined cutting of different types of materials, such as: multiplexes, PAL plywood, solid wood, aluminum profiles, etc.

These hand saws can be equipped with optional guide rails up to 800 mm in length, which can be joined using joint elements.

The guide rails of these manual circular saws are provided with anti-slip rubber layers that facilitate optimal processing.

These models of wood saw allow cutting of pieces with thicknesses up to 85 mm at 90 ° and up to 60 mm at 45 ° ensuring a high processing power due to powerful motors.

The ideal cost-benefit ratio offered by these saws recommends both for exploitation by amateurs, as well as for professional exploitation, in intensive regime.

These types of power saws guarantee accurate cutting and straight cutting.

4.Alligator Saw

For carpenters and builders. Outwardly, this type of saws resemble chain saws, but having a shape of an alligator, cutting equipment is not an endless chain, but two narrow blades.

They are guided by the tire, which ensures stable cutting without dragging the canvases to the side.

The teeth of the tool move towards each other, while vibration is not felt in operation.

Alligators power saws are designed to solve carpentry and construction tasks, but not carpentry.

A long tire makes work easier if you can’t reach the board you need with your hands (you can cut it with the end of the tire).

Alligators power saws are less productive than chainsaws, but safer. Available in various designs (for sawing wood, brick or aerated concrete).

5.Saber saw

Sometimes called an electric handsaw, the saber saw is a type of electric power saw used to cut wood, steel or plastic. Handy and light, it has the great advantage of being able to be used in corners that are inaccessible with other saws.

Thanks to its power, the saber saw allows difficult cuts while being very versatile with the possibility of changing blades easily.

Benefiting from exceptional power, the saber saw is a device capable of withstanding extreme stresses in the context of renovation, DIY and gardening or DIY work.

This type of saw also offers a high quality finish. To make the saber saw work, it must be permanently connected to an electrical grid.

This is its disadvantage, because it is therefore not suitable for a site with a remote source of electricity. If this is the case, you can opt for another more suitable saw model or provide a large extension.

Anyway, having a saber saw is really ideal for quickly completing a cutting task.

Uses of Saber Saw :

- The saber saw is mainly used when there is a need to achieve greater cutting depths.

- The cutting depth for these devices depends solely on the length of the saw blades and the power of the motor. Saber saw blades are available in lengths of just under 300 mm.

6.Reciprocating Saw

Initially, this saw was called reciprocating, which is due to the principle of its action. The electric motor, which is the drive of the mechanism, transmits torque to the gearbox, which reduces the number of revolutions.

And the rotational movement of the shaft under the action of the crank mechanism is converted into a reciprocating motion of the rod (with a saw fixed at the end) which is placed in the mechanism housing on rigid guides.

The rod moves along the axis of the handle, which is the main difference between an electric saber plate and a jigsaw.

This type of saw is universal for various materials and is used for cutting pipes, wood and plastic, as well as for cutting combined materials, such as nailed wood shields, since one blade can cut both metal and wood.

This makes the reciprocating saw an invaluable tool for dismantling walls.

Advantages of Reciprocating Saw:

- Minimal physical effort.

- Quick work.

- Performing curly cuts.

- Wide area of use.

Uses of Reciprocating Saw:

Reciprocating saw is a universal tool, and can be used for various tasks:

- Joinery and repair work.

- Pipe cutting.

- Sawing up logs.

- Pruning trees.

7.Chain Saw

Using this tool, you can quickly cut many materials used in home construction. A narrow saw blade allows you to cut shaped. This greatly expands the scope of use of this type of powered saw.

As the name implies, this saw uses a chain closed in a ring with numerous teeth. Despite the fact that chain saws have a number of features, they are often classified as band saws.

Chainsaws are much more commonly used in woodworking than in any other area. The chain and guide bar are removable, which is why they call the “headset”.

We did not take out the chainsaws in a separate section, because by their knowledge they repeat similar electric saws, but the chain saw is very popular in the “gasoline” version, so let’s say a few words about their differences.

All-weather – chainsaws do not need a dry room, they can be used in conditions of high humidity and even in the rain.

Mobility – a chainsaw will not take up much space and you can take it out of town without thinking about additional power sources, the main thing is not to forget to refuel the tank!

Power – a chainsaw is able to cut a huge tree of any breed, which puts it in a much more advantageous position relative to electric saws. The duration of work.

The working time of the chainsaw can reach up to 10 hours. The gasoline engine is less moody, it will not overheat and is not afraid of high humidity.

Click here to see a comparison between Gas vs Electric Chainsaw

At the same time, a gasoline engine requires more careful maintenance. If in power saws it is only necessary to monitor lubrication and chain tension, then in chainsaws it is necessary to regularly service engine components, monitor lubrication and prepare the mixture.

Therefore, newcomers are sometimes frightened by the purchase of chainsaws, although modern chainsaws from reliable manufacturers (Stihl, Husqvarna) are assembled and executed very well thought out, so they do not require long training and caring for them does not create great difficulties.

The service life of branded chainsaws can reach 10-15 years, which on average doubles that of electric saws.

Uses of Chainsaws:

- Wood processing.

- Construction works.

- Joinery and carpentry.

- Repair work in the garden.

10 Electric bench type of power saws:

1.Electric Circular Table Saw

That might be a personal opinion, but I think the circular table saw is the first machine needed in a woodworking workshop. The larger, the more massive / rigid and the greater the cutting depth, the better.

A table with saw can be purchased or built. Some circulars saw with trade table are very efficient, safe and quiet. The list of accessories of this type of circular saw are many, but the most helpful are those of mechanical advance, movable part of the table and incisor.

It is a version specially designed for workshops that work with wood, but is also used for PAL, MDF, plastic and even some less hard metal variants, such as aluminum.

The cutting disc, provided with sharp teeth, is integrated into the countertop of a work bench and connected to a motor that spins it at high speed.

It cuts easily in straight lines, being very useful when you have to cut boards or cut into two large PAL boards.

However, it requires a larger work surface for installation and is a fixed version, which you can not easily transport if you need to work elsewhere.

It is also among the saw models that have associated one of the highest accident rates, so be careful how you use it and carefully observe all safety rules.

Uses of Table Saw:

- A table saw is suitable for cutting boards, wood and laminate panels. Thanks to the large work table, the workpieces can be placed on the saw blade easily and securely.

- A table saw enables you to cut logs into small, handy and combustible portions.

- Another area of use for table saw is for example series cuts. These are cuts with exactly the same dimensions and sizes.

Table saw

The engraver is very useful only if plywood or foil products are processed on them. Solid wood does not need an incisor. The dangers of operating such a circular, like any blade cutter, are a major test.

I recommend following an instructional period before switching to use. Next we will see other machines, but the circular table can handle the way the others do.

The utility of the other machines appears when we want additional functions, quality, performance and lower material losses.

Depending on your needs and financial possibilities, you can justify additional purchases.

2.Band saw (vertical treadmill)

The second machine I would recommend for purchase is the band saw. The blade of this saw is very thin in relation to the depth it can cut.

Band saws work with a ribbon blade, and they come in all shapes and sizes. Most of them have two wheels and others have three or four wheels.

Some are so large that they are anchored in the foundations of the production halls, and others are so small that they fit into a shoulder bag.

The ribbon blades may have teeth on one or both sides as seen in the image below. In other words, this machine is very flexible and is used for high efficiency and lower material losses.

I say this by comparing it to the circular with the table. The circular blade with the table can cut irregular shapes.

That is, by turning the material you can go on a contour, which can not be done on the circular table. The band saw usually has an upright position when used for cutting wood.

Uses of Band saw:

- The bandsaw is ideal for working wood quickly and precisely. Can also be used to saw complex shapes.

- The band saw offers the advantages of a jigsaw and also makes it possible to cut relatively complex shapes from materials that are neither too large nor too thick.

- Cutting thick pieces of wood resting on the saw table, possibly against a blade guide, is more comfortable than with a hand saw.

- Depending on the width of the band saw, you can saw thicker material. If you do not use the correct blade width, the cut will not be vertical.

3.Miter saw

A miter saw is similar to first view as a hinged circular saw that is attached to a stationary platen.

They are designed to cut angles ranging from 45 ° to 90 ° to form a finished angle with another part. Today, most modern miter saws are also called “radial” to allow better cutting width for large pieces.

These angles are adjusted by turning the table relative to the stop and tilting the “head” of the saw to the side. There are also combined “trimming” with the upper table.

On them, you can perform smooth longitudinal cuts. Another variety – miter saws with a broach, in which the “head” moves the guide rods, so that you can cut wide work pieces.

Uses of miter saw:

- The miter saw is used for sawing at an angle. A possible application for a miter saw is the manufacture of a frame for a table, but also of frames for example.

- Miter saw is used for cross cutting of boards, battens, bars, platbands. One of the varieties of stationary saws. Designed for precise crosscutting with given horizontal and vertical angles.

- It is used to cut at exact angles, dimensions, and lengths. For very detailed work, a scroll saw works great.

These are both quite common tools utilized in woodworking.

4.Compound Miter Saw

It is used for sawing wood, plastic, aluminum and other similar materials at specified angles.

Thanks to the easy and quick adjustment to different angles of the blade, which is mounted on the bracket, this saw is an indispensable tool in woodworking workshops and furniture production.

The compact size and light weight make it possible to use these saws for construction and finishing work at any facility.

A compound miter saw is one of the best ways to save time when you need to trim windows or dock a skirting board.

5.Multi-blade Saw

A multi-blade saw is ideal for cutting a wide range of materials: you need a single tool to cut many different materials. From wood to tiles, from laminated floors to aluminum and PVC.

The multi-blade saw cuts straight lines accurately and is also very useful for deep cutting. A multi-blade saw can be used with different types of saw blades, for example diamond discs, HSS blades and carbide tipped blades. These blades are all available in most DIY stores.

These multi-blade saws are used for sawing timber, equipped with several blades, fixed on the axis at predetermined distances (with the help of distances).

These multi-blade saws can be used for the production of semi-finished products, for the production of furniture, the manufacture of elements for construction in large workshops and for series production.

6.Scroll Saw

A scroll saw is specially designed to allow the cutting operation to be carried out, being equipped with an extremely thin and narrow cutting blade which facilitates cutting according to certain shapes.

A scroll saw is a table saw used to cut precise curves mainly on fine parts.

It is similar to a band saw, but uses a pendulum blade operated by a reciprocating motor.

The fineness of the blade allows it to cut complex patterns better than a jigsaw.

To create different pieces by the drilling enthusiasts, different templates are created or unloaded which can be subsequently cut using a drilling saw.

In order to make a cutting with the help of a scroll saw, it is necessary a careful preparation of the material to be processed, as well as of the shapes to be cut.

The operation of some saws involves pushing the work piece without applying excessive force to the saw blade.

In this case, the work piece is guided with ease because its teeth are oriented for cutting only when it descends.

The use of scroll saw for cutting different parts requires careful preparation of the material and molds to be cut.

In order to obtain the best results with the help of saws for drilling, it is recommended the appropriate choice of blades depending on the material to be processed.

The scroll saw models can be used for cutting and molding on the outside, in which case the operation involves the easy pushing of the molding part towards the cutting canvas and its simultaneous return.

At the same time, scroll saw can be used for cutting and molding inside the work piece. In this case, the cutting canvas is removed and the work piece is positioned on the work table after a cut has been made inside it.

Uses of the Scroll Saw:

- The scroll saw is used to cut difficult curves and complex shapes.

- The use of the scroll saw models for the execution of the cutting and modeling operations has taken on a very large scale, being preferred even by the amateur users.

- With a fine blade, saw the most complex shapes in a material no more than a few millimeters thick. The sawdust is blown by a small plastic tube, which allows you to see the cutting line. The work table can also swivel.

7.Radial Arm Saw

The engine and the blade in this saw are placed on the lever, which passes over the sawing table, which allows the saw with a radial lever to perform identical composite cuts, cuts at an angle and much more.

For various manufacturers, saw blades may be interchangeable, but it is imperative to check the recommended speed for each blade, as some radial saws rotate very quickly.

Uses of Radial Arm Saw:

- In practical operation, the modern radial circular saw offers the user numerous advantages.

- Not only is it ideal for use in the workshop of the hobby DIY enthusiast, it is also highly recommended for professional use in a commercial workshop.

The modern radial arm circular saw also guarantees the user extremely back-friendly work.

Provided it has sufficient power, it always enables particularly precise cuts. It guarantees an overall safe stand and usually has a significantly high engine and ultimately cutting performance.

8.Panel Saw

The vertical panel saw is also called a standing panel saw.

As the name suggests, the vertical panel saw stands or is mounted on a wall. The vertical panel saw makes work easier, as (wooden) panels are cut in the standing position.

The first vertical panel saws could only be used manually. Over time, it became more and more automated.

Most vertical panel saws can now be operated by one person. The latest models can be conveniently controlled via touchscreen. Due to the standing position, this type of panel saw is very space-saving.

Panel Saw are split in two types of saws:

Horizontal panel saw

Horizontal panel saws are also known as horizontal panel saws. Due to their design, horizontal panel saws require a large footprint.

In terms of area and structure, the horizontal panel saw is comparable to a sliding table saw for large systems.

With the horizontally working panel saw, series production is easier to manufacture due to the horizontal work piece.

Vertical panel saw

A special category of circular saws used especially in the furniture processing industry are called vertical saws for formatting panels.

These formatted type of saws are characterized by the special construction, they are equipped with sturdy frames on which are supported the panels to be cut and a system of sliding the cutting head on the length and width of the piece to be cut.

Uses of Vertical Panel Saw:

Vertical panel saws are used for cutting panels from these materials:

- Aluminum composite panels

- Wood and wood-based materials (MDF, particle board)

- Ceramics

- Plastics

- Laminate

- Sandwich panels

9.Plunge saw

In a wood processing workshop, situations may occur frequently where it is necessary to cut a piece of wood, longitudinally or crosswise.For the different cuts of the wooden parts we can used successfully plunge saws models.

A plunge saws is a wood cutting machine provided with a circular disc that ensures cutting of the wood material on a straight axis.

Such a hand-held circular saw offers numerous advantages, being lightweight and allowing mobile use when appropriate.

These hand-held circular plunge saws models are recommended for use on construction sites or during assembly work.

These wood cutting saws are extremely useful to facilitate the processing operations quickly and without additional costs.

These models of wood saws can be used for cutting, cutting, chopping, angle cutting and inclined cutting of different types of materials, such as: multiplexes, PAL plywood, solid wood, aluminum profiles, etc.

These hand saws can be equipped with optional guide rails up to 800 mm in length, which can be joined using joint elements.

The guide rails of these manual circular saws are provided with anti-slip rubber layers that facilitate optimal processing.

These models of wood saw allow cutting of pieces with thicknesses up to 85 mm at 90 ° and up to 60 mm at 45 ° ensuring a high processing power due to powerful motors.

The performances of a circular saw are directly influenced by the quality of the circular disk with which it is equipped, which is why the use of quality consumables is recommended.

The ideal cost-benefit ratio offered by these saws recommends both for exploitation by amateurs, as well as for professional exploitation, in intensive regime.

These multifunctional saws guarantee accurate cutting and straight cutting.

10.Tile Saw

When laying tiles on floors and walls, one thing should not be missing: the tile saw.

At first glance, it looks like a conventional jigsaw. However, if you take a closer look at the tile saw, you will quickly see that the bracket for the saw blade is set higher. But why?

Quite simply – the high holding bracket enables a more pronounced cutting depth, so that the craftsman can also devote himself to larger tiles if necessary.

The tile saw blade also has another special feature. It is wire-like because ceramic, glass or clay tiles tend to splinter. Due to this special nature, it is even possible to cut tight curves.

If rooms have certain models, such as rounded walls or columns, it is all the more important to use this valuable tool.

Either electric tile cutters or the cheaper manual tile saw can be used.The tile saw is specially equipped for ceramics.

This saw is in the form of a sawing machine on a steel cutting table equipped with a removable water recovery tank.

The type of saw is equipped with a water-cooled diamond disc .

Conclusion

Most saws are long lasting and durable.Because saws are very powerful tools you always should were protective equipment when you used them.

In this article we present you 32 of the types of saws and their uses. As you can see each types of saws have different uses. Always take some time to investigate the right type of saw to use for your woodworking project.

Choosing the right saw will be easy now that you know the Different Types of Saws and Their Use 🙂