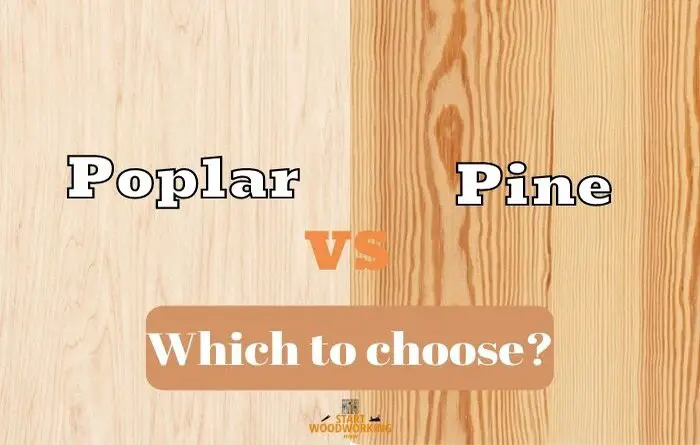

Poplar vs Pine (Which is the Best? | Pros & Cons)

The answer to the question Poplar vs Pine is not that easy! Both have pros and cons and I invite you to discover them in this complete guide I wrote!

Belonging to the Salicaceae family and comprising 35 species, the poplar is a very tall tree with a slender habit. It is currently very widespread throughout Europe.

Pine is the second most common type of wood in Central Europe after spruce . The pine belongs to the conifers and is known by different names.

Poplar wood has some interesting areas of application and also interesting properties throughout. You can find out what properties you can expect from pine wood and what you should pay attention to when processing, as well as much more about pine wood, here.

Let’s see the differences and resembles of these types of woods.

Poplar vs Pine: Color

Poplar Color

Poplar wood is light in color, the sapwood is creamy white, and the veins of the heartwood can vary from yellowish brown to olive green. The green color in the heartwood darkens on exposure to light and turns brown.

Poplar heartwood has light cream to yellowish brown in color, with occasional streaks of gray or green while sapwood has a pale yellow to white color which often cannot be clearly separate from the heartwood.

The wood has a fine texture, with a straight grain. The size of the sapwood and some physical characteristics vary according to the growing regions. Wood has many desirable characteristics and is suitable for a wide variety of important uses.

It can have colors ranging from dark purple to red, green or yellow which tends to darken when exposed to light. Poplar typically has a uniform, straight grain with a medium texture.

In the primary poplar species and the hybrids, the light sapwood is clearly separated from the yellowish to reddish brown heartwood; the wood of the poplar is yellowish white throughout.

Pine Color

The color of pine wood is whitish-yellow to reddish-yellow and darkens to a reddish-brown shade over time. The sapwood of the pine is usually lighter in color. Heartwood, on the other hand, tends to be darker. This natural re-coloring of the wood can be slowed down by treating it with wood preservatives.

Wood browning occurs in any form and regardless of the treatment of the wood. This process is especially favored by direct sunlight. Staining can only be slowed down by using appropriate protective agents and sealants.

The clear grain of pine wood is characterized by contrasting medium brown annual rings, small irregularities and knotholes. The resin channels in the pine wood are visible to the naked eye, and fresh pine wood smells intensely of tree resin.

Sapwood and heartwood poorly distinguished by color, yellowish-white heartwood, often with pinkish-reddish broad spots (in older trees, the heartwood may be brownish in color), moderate brightness, little accentuated smell and taste, characteristic of resin, pleasant , low density, soft to cut, straight grain, fine texture.

The color of the pine can also vary from region to region. Due to the alternation between early light wood and late dark wood, pine wood usually has a strong structure.

Here is a guide how to stain a pine wood doors in 5 easy steps!

Poplar vs Pine: Comparison Table

| Parameters | Poplar | Pine |

|---|---|---|

| Appearance | Not a big difference between heartwood and sapwood. Light brown heartwood and pale yellow sapwood. | Pine has a pale yellow sapwood, the heartwood is darker, ranging from rich yellow to reddish brown. |

| Durability | Classified as a non-durable species against rotting and susceptible to insect attack. | Sensitive to attack by fungi and insects. |

| Density | Light wood, with a density approx. 450 kg / m 3 at 12% humidity. | Approximately 500 kg / m 3 at 12% humidity. Light to medium-heavy wood. |

| Harness | Poplar wood has a Janka Hardness of 2400 N / 540 lbf. Hardness (Brinell) of 10-15 MPa | Depending on the type of pine it has a Janka Hardness of 2200-5100 kN / 490 – 1150 lbf. Hardness (Brinell) of 78.0 MPa |

| Workability | Poplar wood is easy to work with both manual and mechanical tools. | Pine wood has a lower density and it is easy to work with tools and machines. |

| Suitability for finishing | Can be easily stained and painted. | Can be easily varnished and painted. |

| Suitability for assembly | Easy glued. Can be nailed and screwed without difficulty. | Pine can be easily milled, sawed, glued, screwed, stained or painted. |

What is the difference between Poplar and Pine?

The main difference between poplar and pine is that poplar is a hardwood while pine is a softwood. Poplar being a hardwood means they have a more complex woody structure than that of softwoods with fibers.

The colors of hardwoods are very varied from pale to dark brown while softwoods are resinous, soft, with marked annual rings and are of a smooth and uniform pale color and can be impregnated very easily. Normally hardwoods, they are dense woods, little porous so they are very difficult to impregnate.

Poplar, it is fibrous, clear and not very dense with a gray bark with a smooth to slightly rough structure and small, round leaves. Finally, the visible rings of softwoods allow them to be identified quite easily. Do not rely on the weight of the wood to try to identify it.

If it is light, it does not necessarily mean that it is a softwood. Pine wood has a gray-brown, rough trunk with a typical structure of large scales. In addition, depending on the species, it can be easily identified by the long needles.

Poplar vs Pine: Hardness

Poplar is consider a hardwood with a soft to medium hardness which means that it can be processed very well. Pine is a softwood with low hardness. The Monnin hardness index puts Poplar on a 2.6 value while Pine stands at 1.8 to 2.1. This means Poplar is harder and stronger than Pine. Neither pine nor poplar is as strong as a fir, but both weigh less than a fir.

Poplar vs Pine: Durability

Poplar Durability

The wood of the poplar is not very durable. This makes it susceptible to the effects of the weather or to fungus and insects. For this reason, it is not suitable for load-bearing structures outdoors.

Hybrid poplars are specifically bred to improve resistance to disease and insects, as well as to increase production volume under special conditions. Poplar wood is not resistant to core decomposition, however it is extremely resistant to preservative treatments.

Poplar wood is also not well suited for underwater construction. On the other hand, it is often used in interior construction due to its good properties. The wood of the poplar can be worked well with sharpened tools.

Poplar wood is neither weatherproof nor particularly durable. It is also not resistant to fungal and insect attack and must therefore be protected accordingly.

Pine Durability

Pine wood showed low resistance to fungi decay and to the attack of dry-wood termites. Wood is very susceptible to blue stain fungi, termites and marine borers. Occasionally damage can occur from borers from the weevil group. Sapwood is not susceptible to Lyctus wood borers.

When it comes to waterproofing durability pine wood is moderate, with the exception of Mountain Pine which has a higher waterproof resistance.

Pine wood is only moderately to little resistant to fungi, which can destroy the wood. It may therefore not be possible to process it untreated. Outdoor use also requires the wood to be treated with chemical wood preservatives.

Pine wood should not be used in areas where direct splash water can occur, as it can form mold faster when it is damp.

The hardness of the wood is rather mediocre, but that makes it easy to work with, except for resin-rich types. These can be difficult to surface finish.

Between types of pines the Oregon pine is the hardest but even then it still must be pressure treated which increases the resistance to fungi and insects attack. This pressure treat method allows the wood to be suitable for exteriors use in a more economical way.

Poplar vs Pine: Drying

Poplar Drying

Poplar has shrinkage and swelling values in the middle range and result in a satisfactory to good stamina. The natural as well as the technical drying are largely unproblematic, as the poplar wood has little tendency to throw or crack.

However, due to the high initial moisture content, slow drying is recommended. Larger proportions of tensile wood can lead to more pronounced deformations.

Since poplar wood has a fairly even structure, it only shrinks to a small extent when it dries. However, deformations can occur during drying, the so-called “throwing”. Furthermore, the poplar wood is quite soft and susceptible to the effects of the weather.

The wood of the poplar is also susceptible to fungal and insect attack. So that it does not freeze when drying due to moisture, it should be stored in a dry and protected place in a shed, for example.

Pine Drying

In the case of pine wood, drying in the open air is not very recommended, it is necessary to do it in greenhouses and everything must be very well controlled.

Air drying is difficult as it tends to twist and crack. The kiln drying process must be carefully controlled in order to obtain quality wood.

In contrast to woods such as spruce, pine shrinks much more. At the same time, however, the wood deforms less. However, warping of wood is very likely in changing climates. However, wood tends to crack or warp much less than spruce wood.

When drying pine wood, however, care must be taken to keep the temperature low. Higher temperatures are not recommended due to the resin content in the wood.

Is poplar better firewood than pine ?

Polar is not very suitable as firewood, being a particularly elastic and light wood, it is mainly used during the ignition phase because it burns quickly when dry. On the other hand pine is better as firewood, not the best, but acceptable, it develops a sparkling flame that heats quickly.

Being resinous it makes a lot of smoke during the first stages of ignition. Pine cones are a great fuel. Pine wood is a type of firewood that burns very easily and leaves a very good smell, which is why it is more advisable to use it for bonfires .

Poplar, on the other hand, is classified in the category of soft hardwoods, such as birch for example. Its calorific value is therefore limited (1,400 kWh / cubic meter).

Poplar vs Pine: Uses

Poplar Uses

Poplar wood is used in:

- carpentry;

- industrial and light rafters;

- furniture and parts thereof (eg, frames, sofa beds, cabinet boards);

- light packaging (cheese boxes, crates), heavy packaging (crates, pallets) and packing wool;

- various panels:

- plywood;

- veneer for decorative cabinetry and interior fittings;

For a long time, its wood was used for the construction of frames. Today, the beautiful logs are used in peeling: they are made into slatted or plywood panels; it is also made into cheese boxes, light wrappers for fruits and vegetables, oyster baskets or matches. The second quality is often used for the manufacture of pallets, crates or pulp.

Poplar wood is occasionally used as construction timber, but only for structures that are exposed to correspondingly low loads and do not require a high load-bearing capacity. It is problematic outdoors, so it is mainly used for indoor use. Poplar wood is also used comparatively often in the packaging sector.

Poplar is a light and soft wood but not widely used to build furniture, it is used instead to make matches or ribbons obtained from the veneer which is a system of obtaining from the tree trunk a sheet as high as the trunk and as long as the trunk it was a roll of paper. Basically, with the help of a long blade, the tree is unrolled. Paper is made with poplar pulp.

Pine Uses

Pine wood is used in many areas:

- for furniture production (solid wood or veneer wood)

- Round timber and sawn timber

- for the production of wood-based materials (chipboard)

- in house construction

- as firewood

- for paper production

- for packaging (boxes, pallets, etc.)

Pine wood is mainly used in furniture construction, for example in cupboards, tables or chairs as solid wood or as veneer. Is also available as round or sawn timber and is also used in the manufacture of chipboard and fiberboard.

Pine wood plays a central role in the manufacture of paper and cellulose. As a building and construction timber, pine is found in many roof structures, wooden cladding, window and door frames. Since pine wood has good burning qualities, it is used as fuel for appropriate heating systems.

In furniture production, pine wood is often used as a material for cupboards and beds, but also as a floor covering. Pine wood is used in house construction for roofs, terraces, fences, window frames, doors and facades. The interior work also often relies on pine, because it is suitable for stair, wall and ceiling cladding as well as built-in furniture

Furniture, solid wood beds, bedside tables, slatted frames and many other products are made from pine wood for the living and sleeping areas. Pine wood is very popular in everyday life as living room or bedroom furniture.

Poplar vs Pine: Workability

Poplar Workability

When we are talking about wood, workability is a very important concept, as it will dictate whether the material is good or not to be handled.

In this way, the wood of the poplar can be peeled or sawed cleanly. Likewise, the poplar wood can often be processed well with tools whose cutting surface is on the long edge (knives). The poplar wood does not tend to crack during processing.

Staining of the poplar wood is very possible because the wood can absorb the stain well. It can be glued well, but is not as easy to polish. Gluing with commercially available glues as well as surface treatment with common means do not cause any difficulties, but the high absorbency of the wood must be taken into account.

White, soft and light, poplar wood is easy to glue, stain, paint, nail or staple, but very difficult to sand or saw.

Poplar does not split when fixed with nails, it is easy to work mechanically but has a slightly irregular surface. It is possible to turn it over, screw it on, and sand it satisfactorily. It is easy to paint or varnish, producing a good finish, although it requires attention to uneven surfaces. The numbness ranges from low to moderate and offers good dimensional stability.

Pine Workability

Pine wood is one of the soft to medium-hard woods and is therefore very easy to work with. It’s elastic and doesn’t break easily. In the untreated state, pine wood is not very weather-resistant and quickly rots when it comes into contact with earth.

Treatment with wood preservatives therefore extends the lifespan of pine wood considerably. Pine wood is very sensitive to high temperatures and tends to leak resin.

In the case of pine wood , the species promotes softness to the cut and can be worked with machines or hand tools and very easy to carve.

In addition, it can also receive various types of finish and can be fixed with special glue. So, in short, it’s a great species to work with.

Pine wood is easy to work with hand tools or machines. If compression wood occurs, there may be distortion during planing. Easy to stick and accepts surface finishes well. It is easy to unfold, flatten and glue for a good finish.

Poplar vs Pine: Advantages and Disadvantages

Poplar Advantages

The advantages of poplar wood are:

- Good unwinding ability

- Fast drying

- Ease of processing (easily polished and painted)

- Uniform white texture (mat or satin)

- Easy to paint and stain

- Lightness

- Clarity and Homogeneity

- Perfect for the manufacture of plywood (acoustic and decorative) and slatted panels.

Poplar Disadvantages

The disadvantages of poplar wood include:

- Needs to be treated for outdoor use

- Vulnerable to humidify and fungi

- Brittle

- Soft and woolly

- Unpleasant odor when burned

Pine Advantages

Pine wood has the following advantages:

- Cheap

- Resistant to warpage

- Environmental friendliness

- It lends itself well to all types of processing

- Easy to paint

- Has a beautiful texture

- Light weight

- Does not accumulate or emit harmful substances

Pine Disadvantages

Here are the pine wood disadvantages:

- Not weatherproof

- Susceptible to blue fungus

- Sunlight changes the color

- Is very resinous, therefore, when working with it and on the final product, it can sometimes release resin

- Pine furniture is easily prone to dents or scratches

Conclusion

Pine wood is a good compromise between expensive premium wood and cheaper alternatives that are difficult to work with. It is one of the cheaper woods, but still feels of high quality. It is also easy to work with.

Poplars are fast-growing sources of wood for a wide range of uses. Mainly crosses of different poplar species are used for the industrial wood utilization. For the professional craftsman and hobby do-it-yourselfer, the wood of the poplar is suitable, for example, for interior construction, use as plywood panels and other things.

When deciding poplar vs pine wood you want to use for a project, be aware of the processing steps the wood has to undergo. You can also base your decision on color and the need for the wood to be weatherproof.